Unleashing Precision in a Small Package

The allure of shaping raw metal into a precise, functional part is compelling for hobbyists, model makers, and small-workshop owners alike. The mini lathe has democratized precision machining, opening doors to work once reserved for industrial facilities. However, one critical challenge separates casual metalworkers from those serious about their craft: working with steel.

Machining steel demands substantially more from a tool than aluminum or brass, requiring a combination of power, rigidity, and precision that separates capable machines from those merely pretending to be metalworking benchtop lathes. Steel’s hardness, resistance to deformation, and heat generation during cutting set it apart as the true test of any lathe’s capability.

The broader metal cutting machine market, valued at USD 6.10 billion in 2024, reflects growing demand for capable tools across industries. This comprehensive guide navigates the essential features of metal lathes designed specifically for steel, compares top brands and models, and provides the insights needed to choose a machine that will become the centerpiece of your metalworking workshop—not merely an expensive bench ornament.

What Is a Mini & Compact Lathe for Metal?

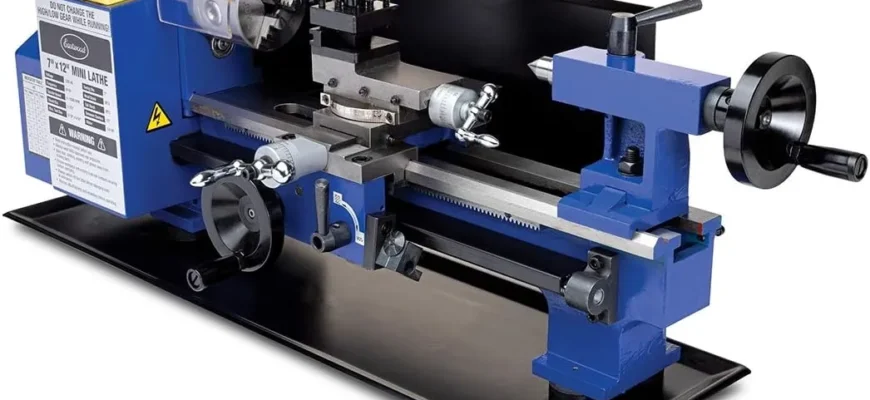

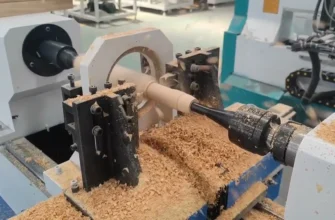

A mini lathe or benchtop lathe for metal is a scaled-down version of industrial machinery, engineered to fit into home workshops and garages while maintaining the precision required for serious metalwork. Often called a precision mini lathe or simply a metal lathe, this machine performs fundamental operations: turning, facing, drilling, knurling, and metal threading.

Unlike wood-turning lathes built with lighter construction, a true metal lathe features a rigid cast-iron bed, a precise leadscrew, and a powerful motor designed to handle the cutting forces inherent in machining ferrous metals. The spindle bore determines the maximum diameter of material that can pass through the headstock, while the distance between centers defines the workpiece length capacity.

Why a Dedicated Guide for Metal & Steel?

The difference between rigidity in a lathe and inadequate construction is dramatic when working with steel: a capable machine cuts smoothly and delivers excellent surface finishes, while a less rigid machine suffers from tool chatter, which ruins workpieces and damages tools.

Machining steel is the true test of a lathe’s capability. Steel is significantly harder and more demanding to cut than softer metals. It requires:

- Lower spindle speeds (typically 200-800 RPM for larger diameter workpieces)

- Higher torque at those lower speeds

- Exceptional rigidity to prevent deflection and chatter

- Precise feed rates and tool geometry

A benchtop lathe that excels with aluminum—where light cuts and higher speeds work well—may stall or produce poor results with steel due to insufficient torque, inadequate rigidity, or thermal issues. This guide focuses exclusively on machines and practices that possess the strength and precision necessary for steel machining, saving you from costly mistakes.

Why Choose a Mini & Compact Lathe for Metalworking?

The metal lathe market in North America is valued at USD 1.2 billion in 2024 and continues to expand, driven by the accessibility these machines offer.

Advantages for the Metal Enthusiast

Space Efficiency: The primary advantage is clear—a benchtop lathe fits into a garage corner, basement, or small workshop without requiring dedicated industrial space. This accessibility has democratized precision metalworking for hobbyists and small businesses.

Cost-Effectiveness: Mini metal lathes offer affordable entry into precision machining, allowing skill development and high-quality parts production without the five-figure investment required for full-sized industrial equipment.

Versatility: Despite compact dimensions, these machines handle an impressive range of components—from custom bolts and threaded rod work to bushings, model engine parts, and specialized tooling. A mini metal lathe can work aluminum, brass, steel, and stainless steel with appropriate technique.

Skill Development: Operating a lathe machine is foundational training in mechanical engineering and fabrication. Hands-on experience with spindle speed optimization, feed rates, and tool geometry builds expertise applicable to larger machines and professional work.

Realistic Limitations for Metal & Steel Machining

Workpiece Size: The swing (maximum workpiece diameter) and distance between centers are limited. A typical 7×12 mini metal lathe swings 7 inches and spans 12 inches between centers—suitable for small parts but not large projects.

Depth of Cut: Lower rigidity and mass compared to industrial machines necessitate lighter cuts in steel. Attempting aggressive material removal can cause chatter, damage the motor-drivetrain connection, and produce poor surface finishes.

Material Hardness: While capable of machining mild steel and many alloy steels, mini lathes struggle with hardened or exotic tool steels. Success depends on sharp tooling, correct speeds, and patience.

Duty Cycle: Most mini lathe motors are not rated for continuous heavy operation. Extended steel-cutting sessions may require cool-down periods to prevent motor overheating.

Key Features & Specifications for Metal Machining

When evaluating a mini metal lathe for steelwork, these specifications determine success:

Motor & Power: The Driving Force for Steel

The motor is the lathe’s foundation. For steel, you need:

- Sufficient horsepower with consistent torque at lower RPMs (where steel cutting occurs)

- Most entry-level benchtop metal lathes feature 250W to 750W motors (0.33 to 1 HP)

- Variable-speed control to dial in precise spindle speeds for different materials and diameters

- A digital RPM readout (or even a simple LED screen for readout) for accuracy and repeatability

Mid-range models often include 500W to 750W motors, while Harbor Freight’s Central Machinery and similar imports may start at 250W (1/3 HP). The torque curve—how power is delivered across the speed range—matters more than raw wattage for steel cutting.

Construction & Rigidity: The Foundation of Precision

Rigidity is paramount for steel machining. Any flex or vibration transfers to the workpiece, resulting in poor finishes and dimensional inaccuracy.

Essential: A lathe bed, headstock, and tailstock made from solid cast iron. The heavier the machine, the better it dampens vibrations. Hardened and ground bedways are a premium feature ensuring long-term accuracy and smooth carriage travel. Premium machines like the Emco Compact 5 feature ground steel dovetailed ways; others use cast-iron beds with adjustable gibs for wear compensation.

Spindle & Chuck: Secure Workholding

The spindle holds the chuck, which grips the workpiece. For steel work:

- A robust spindle with deep-groove bearings or sealed ball bearings

- A 3-jaw chuck (self-centering and quick) or optional 4-jaw independent chuck (for complex shapes and precision centering)

- Spindle bore size (typically 0.625″ to 1.25″ on mini lathes) determines the maximum diameter of stock passing through the headstock

- Hardened chuck jaws providing reliable, repeatable grip

The precision mini lathe category emphasizes chuck runout and concentricity—typically better than 0.01″ on quality machines.

Precision & Control: Achieving Tight Tolerances

Accuracy is the ultimate goal in metalworking. Critical components include:

- A precise leadscrew allowing accurate automatic feeds and specific thread cutting pitches

- Handwheel dials with fine graduations (typically 0.001″ or 0.025 mm)

- Minimal backlash (slop) in cross slide, compound, and carriage movements

- Adjustable gibs for wear compensation as the machine ages

The global precision machining market, expected to reach USD 180.25 billion by 2030, underscores the value of machines delivering tight tolerances.

Top Mini & Compact Lathes for Metal & Steel: A Comparative Review

The mini lathe market spans entry-level imports to precision European machines. Each tier serves different needs and budgets.

Entry-Level & Hobbyist Picks: Good Value for Metalworking

This tier is dominated by Chinese-manufactured mini metal lathes, often sold under various brand names including VEVOR Mini Lathe Machine and other imports. The most common configuration is the 7×12 or 7×14 mini lathe (7-inch swing by 12 or 14 inches between centers).

Pros:

- Highly affordable ($200-400 USD)

- Massive community support and aftermarket ecosystem

- Wide availability of replacement parts and upgrade kits

- Readily available metal gear upgrade kits for the stock plastic drivetrain

Cons:

- Inconsistent quality control and finish

- Require significant cleaning, deburring, and adjustment out of the box

- Stock plastic gears in the drivetrain are a known failure point under steel-cutting loads

- Many users quickly upgrade to metal gears to ensure reliability

- Base construction lacks the rigidity of mid-range or premium machines

Best For: Budget-conscious hobbyists willing to invest time in setup and comfortable performing upgrades.

Mid-Range & Performance-Oriented: Enhanced Metalworking Capabilities

Brands like Grizzly Industrial have established themselves by offering improved versions of import designs. The Grizzly G8688 (also available as the Model 5100/5200 in some contexts) represents a meaningful step up in quality:

Specifications (Grizzly G8688 example):

- Motor: 250W (1/3 HP), variable speed 100-2500 RPM

- Swing: 7 inches, Distance between centers: 12 inches

- Spindle bore: 0.78″ (20mm), Morse Taper: MT#3

- 3-jaw chuck (3 inches) with external jaws included

- Turret tool post, leadscrew (16 TPI), complete change gears

- Includes steady rest, MT#2 dead center

Pros:

- Better out-of-the-box fit and finish

- More reliable quality control

- Domestic customer support (US-based for Grizzly)

- Often larger spindle bore and more powerful motors than entry-level imports

- Superior surface preparation and paint

Cons:

- Higher price ($400-800 USD)

- Still may benefit from upgrades and refinement for optimal performance

- Not as rigid as premium or vintage machines

Best For: Serious hobbyists and small businesses seeking reliability and support without premium pricing.

Premium & Vintage Options: High-Precision Metalworking

This tier includes modern precision brands and revered vintage machines, each offering exceptional accuracy and rigidity.

Modern Premium Machines:

- Sherline lathe: Made in the USA, available in tabletop (8″ bed) and benchtop (17″ bed) configurations. Known for exceptional accuracy, hardened ground ways, and precision. Ideal for model makers and fine-scale work. Available with ball screw options for CNC conversion. Sherline precision lathes emphasize tight tolerances and smooth operation, though they may lack rigidity for heavier steel cuts due to their lighter construction.

- MicroLux 7×16 (Micro-Mark): The only true imperial (inch) feed screw mini lathe on the market. Features 500W brushless DC motor, electronic variable-speed control, and 0.050″ calibrated dials. Superior to metric-based competitors for traditional inch-system work. Ideal for precision work but with the size limitations inherent to mini machines.

- Taig Micro Lathe II: A precision machine featuring a precision ground steel bed, sealed ball bearings, and 6-speed positive vee-belt drive. Offers 0.0005″ overall working accuracy and 0.001″ cross-slide dial graduations. Maximum swing: 4.5 inches (extendable to 6.5″). Excellent for detailed metalwork on small-scale projects.

Vintage Machines:

- Emco Compact 5 (Austrian): A legendary small CNC or manual lathe from the 1980s, renowned for rigidity and precision. Center height: 65mm (2.56″), distance between centers: 350mm (13.78″), spindle speeds: 200-2400 RPM, motor: 500W. Highly sought by machine enthusiasts for its exceptional build quality. Original models command $1,000-2,000; found machines vary widely in condition.

- South Bend 9 (American classic): Manufactured since 1914, the South Bend 9 set the standard for small precision lathes. Multiple models exist (Model A, B, C, and specialized variants). Typical specs: 9-inch swing, 24-inch distance between centers, multiple speed options. A well-maintained South Bend 9 remains a benchmark for quality and capability in small-to-mid-size lathes. Availability and condition vary; prices $500-2,000+.

- Sieg SC4 (Chinese import, premium version): Offers infinitely variable speed, 110mm swing, 510mm center distance, 1.25kW motor (1.68 HP), and 1,000-2,000 RPM speed range. More rigid than basic imports despite Chinese manufacture. Better for serious hobbyists than ultra-cheap alternatives.

Vintage Advantages:

- Industrial-grade build quality with cast-iron beds and precision-ground ways

- Exceptional rigidity for their size

- Often available at reasonable prices (especially American machines)

- Parts ecosystem through enthusiast communities

Vintage Challenges:

- Availability varies; finding specific models requires patience

- Condition assessment requires expertise

- Replacement parts may require sourcing from online forums or specialized dealers

- No manufacturer support (usually)

What to Expect from Each Tier for Steel Metalwork

| Tier | Capabilities | Limitations | Best Practice |

|---|---|---|---|

| Entry-Level | Light cuts, aluminum/brass-ready, basic steel capability | Requires tuning, plastic gears fail on steel, less rigid | Plan for 250-500W motor upgrades; upgrade gears immediately for steel work |

| Mid-Range | Reliable steel cutting, better finishes, less setup needed | Still benefits from improvements; not industrial-grade | Out-of-box usable; upgrade gears for heavy steel work |

| Premium/Vintage | Excellent precision, rigid, handles steel well | Smaller swing/capacity than mid-range; vintage parts sourcing | Precision work in steel; excellent for model makers and detailed projects |

Essential Accessories & Tooling for Metal Machining

The lathe is only part of the equation. Proper tooling and accessories are essential for successful steel machining.

Cutting Tools: The Sharp Edge of Metalworking

For steel, two primary tool materials compete:

High-Speed Steel (HSS):

- More affordable ($5-30 per tool)

- User-grindable into custom geometries

- Forgiving of minor rigidity issues and chatter

- Lower cutting speeds required (100-200 SFM for steel typical)

- Excellent choice for learning tool geometry and metal threading

- Can produce sharp edges sharper than carbide

Carbide Inserts:

- More expensive ($15-100+ per tool)

- Superior hardness and heat resistance

- Allows faster cutting speeds (300+ SFM possible)

- Longer tool life on production runs

- Less forgiving of chatter and rigidity problems

- Ideal for production but overkill for hobby use

Recommendation for Mini Lathes: High-Speed Steel is typically the better choice, offering flexibility, learnability, and forgiveness of the rigidity constraints inherent to mini lathe machines.

Workholding & Setup: Securing Your Metal Workpiece

Beyond the standard 3-jaw chuck:

- 4-jaw independent chuck: Allows gripping square, rectangular, and irregular shapes; enables extreme precision centering

- Live center: For the tailstock, essential for supporting longer workpieces and reducing deflection

- Dead center: For fixed tailstock support (less common in modern setups)

- Collets (if compatible): For repeatable, precise workholding of round stock

Measuring & Inspection: Ensuring Metalworking Accuracy

Precision machining requires precision measurement:

- Digital calipers: Basic capability (±0.01-0.02″)

- Micrometer: Necessary for measuring to within 0.001″

- Dial indicator: Essential for lathe alignment, runout checking, and spindle centering verification

- Surface gauge: For layout and reference measurements

- Thread pitch gauge: For verification of threading operations

Specialty Metalworking Attachments

Quick-Change Tool Post (QCTP): One of the highest-impact upgrades. Allows tool swaps in seconds with pre-set positions, dramatically improving workflow and precision. Popular AXA qctp style fits most mini lathes.

Steady Rest / Follow Rest: Provides additional support for long, slender workpieces, preventing deflection under cutting pressure. Critical for precision work on thin material.

Threading Attachment / Change Gears: Essential for precise thread cutting. Most mini lathes include basic change gears; additional sets expand thread pitch options.

Mastering Metal Machining on Your Mini Lathe

Basic Metal Turning Operations

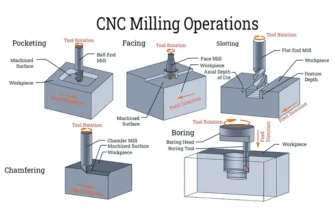

Facing: Creating a flat, smooth surface on the end of a workpiece using the cross slide feed.

Turning: Reducing diameter to specific dimensions; the most common operation.

Drilling: Using a drill bit in the tailstock to create holes along the workpiece center axis.

Parting: Using a specialized thin tool to cut finished sections from main stock.

Advanced Metalworking Techniques

Metal Threading (External & Internal): Using the leadscrew and change gears to cut precise threads. Requires careful setup, proper speeds, and patience. A threading attachment simplifies setup.

Taper Turning: Creating conical shapes by offsetting the tailstock or setting the compound at an angle.

Knurling: Creating textured, grippable surfaces using specialized knurling wheels.

Multiple-step Operations: Chaining operations (drilling, boring, threading) for complex part creation.

Safety First: Essential for Metal Machining

- Always wear safety glasses: Metal chips, especially from steel, are hot and sharp

- Never wear gloves, loose clothing, or jewelry: Rotation machinery catches these instantly

- Know the emergency stop: Every operator should instantly locate and be familiar with E-stop mechanisms

- Keep work area clean: Clutter invites accidents and interferes with work quality

- Never reach into rotating machinery: Wait for complete stop

- Secure workpieces: Loose workpieces become projectiles

- Support longer workpieces: Prevent deflection-related accidents

Maintenance & Longevity for Your Metal Lathe

Proper maintenance keeps your investment accurate and reliable. The value of well-maintained machine tools is projected to increase significantly in coming years as quality equipment becomes scarce.

Regular Cleaning & Lubrication

After every use:

- Brush away all metal chips, especially from bedways and leadscrew

- Steel chips cause rust if left in contact with cast iron

- Apply thin coating of way oil to all sliding surfaces

- Lubricate headstock gearbox and change gears per manufacturer specifications (typically monthly or quarterly)

Alignments & Adjustments

Periodically verify:

- Headstock to bedway alignment (should be straight, not producing tapers)

- Tailstock alignment (should be coaxial with spindle)

- Gib adjustments on cross slide and compound (remove backlash while maintaining smooth movement)

Sourcing Replacement Parts

Popular Import Lathes (7×12, 7×14 size):

- Extensive aftermarket ecosystem: metal gear kits, QCTP sets, specialty tooling widely available

- Online communities (Hobby Machinist Forum, CNC Zone Forum, Practical Machinist) provide guidance

Premium/Vintage Machines:

- Emco machines: Enthusiast communities, specialized dealers, some original factory support

- South Bend: Large spare parts ecosystem through dealers and forums; SouthBendLathe.com maintains catalogs and parts listings

- Sherline and Taig: Factory support and spare parts availability through manufacturers

Recommended Models by Use Case

Best Value for Steel Beginners

VEVOR 7×12 Mini Lathe (with metal gear upgrade): Entry price point with proven community support and easily available metal gear upgrades. Plan to upgrade gears immediately for steel work; budget an additional $100-150 for this critical upgrade.

Best Mid-Range All-Rounder

Grizzly G8688 (7×12): Superior out-of-the-box quality, US-based support, readily available parts. Sweet spot between price ($500-700) and capability. Suitable for serious hobbyists working in steel with reasonable expectations about workpiece size.

Best for Precision & Production

Sherline Benchtop Lathe (17″ bed): Made-in-USA precision, extensive CNC conversion support, excellent documentation. Premium pricing ($2,000-3,500) justified by accuracy, customer service, and upgrade path. Ideal for model makers, educational use, and precision work.

Best Vintage Find

Emco Compact 5 or South Bend 9 (if available in good condition): Exceptional build quality and rigidity at $1,000-2,500. Requires research and patient sourcing but rewards the effort with industrial-grade capability. Excellent for users comfortable with older equipment and willing to learn machine history.

Conclusion

Choosing the best mini or compact lathe for metal and steel work requires balancing ambition, budget, and realistic workshop constraints. The market offers solutions at every price point, from $200 entry-level machines to $3,500+ precision instruments.

Entry-level benchtop lathes from VEVOR and Harbor Freight offer unbeatable value for budget-conscious hobbyists, provided you are prepared to perform setup, tuning, and immediate upgrade to metal gears for reliable steel machining.

Mid-range machines from Grizzly Industrial provide the reliability and support desired by serious hobbyists, stepping up quality and out-of-the-box usability without requiring extensive initial modifications.

Premium machines from Sherline, MicroLux, and Taig, or well-maintained vintage classics like the Emco Compact 5 and South Bend 9, deliver the precision and rigidity demanded by professionals, model makers, and users requiring production-ready capability.

Regardless of your choice, success in metal machining hinges on prioritizing rigidity, ensuring adequate power with variable-speed control, using sharp and appropriate cutting tools, and maintaining realistic expectations about workpiece size. The journey into precision metalworking is deeply rewarding, and with the right lathe machine, your workshop becomes a hub of precision engineering and creative possibility.

As the overall lathe machines market is expected to reach USD 12.98 billion by 2032, investing in quality equipment and skills today positions you perfectly for a future in precision metalworking and fabrication.