Unleashing Your Woodturning Dreams Without Draining Your Wallet

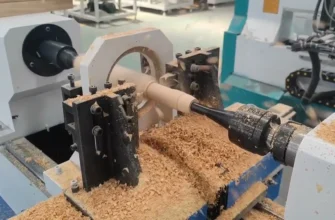

Woodturning captivates with its magic—the transformation of raw wood into beautiful, functional objects through skill and creativity. Many beginners assume this hobby always comes with a high price tag. Fortunately, the global wood lathe market, valued at approximately USD 0.22 billion in 2024, caters to a wide range of budgets and needs. This comprehensive guide will navigate you through the process of selecting a wood lathe that maximizes your value—delivering reliable performance, essential features, and durability for the money—so you can turn your creative visions into reality.

The Myth of Expensive Hobbies: Why “Value” Trumps “Cheap”

Choosing the cheapest wood lathe—or any power tool—is rarely a smart path for beginner woodturners. A “bargain” lathe that vibrates excessively, comes with an underpowered motor, or poor-quality tool rests can quickly turn woodworking dreams into frustration or even introduce safety hazards. Real value comes from finding an affordable lathe that’s robust enough to last as your skills grow. This trend reflects a broader movement: the entire DIY home improvement market is projected to reach USD 1.17 trillion by 2030, with increasingly savvy buyers seeking quality over short-term savings. In the woodworking world, investing in value—rather than just the lowest cost—is an investment in safety, learning, and satisfaction.

What You’ll Discover in This Guide

Expect actionable, jargon-free advice that:

- Defines what makes a wood lathe a “smart buy.”

- Details essential features for beginners and growing hobbyists.

- Offers curated recommendations across new and used markets.

- Covers what tooling and accessories you truly need to get started.

- Injects expert tips and answers to common questions you’ll find in forum rules and user discussions.

This article incorporates essential NLP keywords for discoverability and relevance, such as wood lathe, mini lathe, variable speed, tool rest, midi lathe, full-size lathe, distance between centers, tool rest stem, belt tensioning system, phase converter, and more.

Understanding True “Value” in Wood Lathes

Value is not synonymous with “cheap.” In woodturning, real value means maximizing performance, features, and longevity for your dollar expense—not just finding the lowest price.

- Performance: Smooth, accurate turning without excess vibration. Look for cast iron construction, not stamped steel, and a balanced motor—typically 1/2 to 1 HP for most starter models, more for ambitious projects or full-sized lathes.

- Features: Prioritize variable speed (either a manual belt/pulley system or, better, electronic variable speed control). This is especially relevant for tasks like roughing bowl blanks or pen turning, where control is critical. Helpful features include an adjustable tool rest stem, robust tool rests, and a clear variable speed knob or digital RPM readout.

- Longevity: Solid build quality, brand reputation, and support. Models such as the RIKON 70-105 and entry-level Grizzly G0462 are known for reliability and aftermarket parts support.

Price Range

Entry-level wood lathes range from $229 to $966 or more. The trick: find a model with cast iron or heavy-duty construction, motor capacity to match your projects, and high resale value—especially essential if you later trade up or sell on the used market.

The Cost of Ownership: Cheap Isn’t Always Cheaper

Low-quality, cheap lathes often come with hidden costs:

- Quick motor upgrade when tackling hardwoods (especially for projects like baseball bats or stackable bowls).

- Poorly machined tailstock or tool rest replacements for safety and accuracy.

- Down-time, repairs, and sometimes incompatible aftermarket accessories (e.g., headstock Morse taper or spindle thread size).

- Increased frustration, leading many to give up woodworking prematurely.

Investing a bit more in value-focused models (including budget options from Harbor Freight or Canadian Tire) often pays off: less downtime, more enjoyment, and better long-term results.

Essential Features for a Value-Packed Wood Lathe

Capacity: Swing Over Bed & Distance Between Centers (DBC)

- Swing Over Bed: Maximum workpiece diameter. 8–10 inches suits small projects like pens and olive wood pens; 12 inches or more allows for bowls and hollow forms.

- Distance Between Centers: The maximum spindle length—for furniture spindles, baseball bats, or longer projects, look for a DBC of 15–20 inches.

Power and Control: HP & Variable Speed

- Motor: Aim for 1/2–1 HP for mini/midi lathes, 1.5–2 HP or more for full-size models.

- Variable Speed: Electronic variable speed control makes wood turning smoother and safer. Some models use VFD (variable frequency drive) or a simple belt switching system. Digital readouts and a variable speed knob are helpful upgrades.

Construction and Stability

- Look for a cast iron bed, heavy-duty headstock, and a substantial tailstock chuck. Adequate weight (even for mini lathes) improves cut quality and safety.

- For reliability, ensure the tool rest and tool rest stem are solid and easy to adjust.

Compatibility: Spindle Thread Size & Morse Taper

- 1″ x 8 TPI and MT2 Morse taper are widely supported and compatible with most upgrade chucks (e.g., Nova 3G chuck set, Nova Neptune, or precision pen mandrel set).

- Verify these specifications for easy accessory upgrades.

Lathe Categories: Choosing the Right Style for Your Shop

| Type | Swing | DBC | Motor | Best For | Value Models / Tips |

|---|---|---|---|---|---|

| Mini Lathe | 8–10″ | 12–20″ | 1/3–1 HP | Pens, stoppers, small bowls | WEN 3421, RIKON 70-105, Delta Midi |

| Midi Lathe | 12–14″ | 18–25″ | 3/4–1 HP | Bowls, spindles, all-around | WEN 3424T, RIKON 70-150VSR, Nova Neptune, Harvey T40 |

| Full-Size Lathe | 16–24″+ | 36″+ | 2–3 HP+ | Furniture parts, platters, large bowls | Grizzly G0462, Oneway 2424, entry options from Harbor Freight, used market bargains |

Top Recommendations: Best Value Wood Lathes (2025 Update)

Best Value Mini Lathes

- WEN 3421 8”x12” Variable Speed Mini Lathe

- Variable speed (750–3200 RPM), digital readout, great for pen turning and DIY projects.

- Affordable, reliable, and widely available.

- RIKON 70-105

- Robust cast iron bed, easy belt changes, perfect for small to mid-sized woodworking projects. Reliable for olive wood pens and stackable bowls.

Best Value Midi Lathes

- WEN 3424T 12”x18” Variable Speed Midi Lathe

- Strong 3/4 HP motor, ideal swing and DBC, excellent for bowls and spindles.

- Electronic variable speed.

- Grizzly G0462

- Well-priced, sturdy, with a 16” swing—almost a full-sized lathe but at midi lathe pricing.

- Rikon 70-150VSR / 70-1420VSR

- Strong performance, digital speed controls, flexibility for future upgrades.

Used Market and “Hidden Gem” Bargains

The used market is ripe for those willing to inspect before buying:

- Vintage Delta and Powermatic, Record Power Herald, and older Craftsman models offer legendary durability.

- Seek on woodworking forums, Facebook Marketplace, local turning clubs, and specialty sites like Klingspor Woodworking Extravaganza.

- Always review forum rules about buying and selling.

- For metal-lathe converts considering woodturning, look for sturdy machines like the Precision Matthews 12×36 or Logan 200 metal lathe (with or without phase converters).

Inspection Checklist Before Buying Used

- Run motor through all speeds; listen for bearing noise.

- Test spindle for runout/wobble.

- Slide tool rest and tailstock across the bed—ensure smooth movement and secure lockdown.

- Check all adjustments and safety features (tool rest stem, belt tensioning system, tailstock chuck, max turning diameter and length).

- Ask for demonstration (especially using chucks like Nova 3G or Nova Neptune).

- Ensure all accessories (face plates, workholding tools, impact socket extensions, and dust collector) are included or budget to buy.

Essential Accessories and Tooling for Value Wood Lathes

Safety Gear

- Full-face shield (never rely solely on safety glasses)

- Dust mask or respirator for sanding

- Well-lit, clutter-free workspace

- Avoid loose clothing or jewelry while turning

Tooling and Workholding

- Starter set of HSS gouges (roughing gouge, spindle gouge, bowl gouge, parting tool, scraper)

- Optional: Carbide-tipped tools for ease of maintenance, especially for beginners

- Four-jaw scroll chuck for bowl turning and hollow forms

- Morse taper accessories (tailstock center, drill press attachments)

- Faceplates for larger blanks

- Pen turning enthusiasts: Pen mandrel set, pen press

Maintenance & Finishing

- Keep tools sharp; invest in a sharpening system or jig.

- Polish finishes: Renaissance wax polish, Yorkshire abrasive paste, Mylands friction polish for added shine.

Start Smart, Turn With Confidence

Getting started in woodturning does not require huge expense—just a smart, value-focused approach. Prioritize solid, proven basics like cast iron construction, appropriate power, and compatibility with common accessories. For most hobbyists, a well-chosen midi lathe or a thoughtfully inspected used machine will enable a vast range of woodworking projects far into the future. Invest sensibly in both your machine and basic safety gear, and let your creativity lead to beautiful, useful results.

Next Steps

- Define your workspace (mini, midi, or full-sized lathe?)

- Explore both recommended new and used options

- Prioritize safety and tool quality over quantity

- Connect with local or online turning clubs and forums for advice and deals

- Begin with starter projects (pens, bowls, spindles) and expand your capabilities as your confidence grows

By following this guidance and focusing on genuine value—rather than the allure of the lowest price—you’ll unleash your creativity, avoid common beginner frustrations, and join a thriving, supportive community of woodturners worldwide.

References

“Wood Lathe Market Size & Share,” Verified Market Research, 2024.

“DIY Home Improvement Market – Growth, Trends, COVID-19 Impact, and Forecasts,” Mordor Intelligence, 2025.