Small Automatic Capstan Lathes

Small automatic capstan lathe machines represent a crucial intersection between manual precision machining and modern automation. These versatile tools have remained indispensable in manufacturing workshops, despite the rise of CNC technology, because they deliver rapid production cycles for repetitive small components at a fraction of the cost and complexity of computer-controlled systems.

A small automatic capstan lathe machine is typically defined by its spindle swing capacity of 100-300mm (roughly 4-12 inches), making it ideal for producing components like fasteners, fittings, and precision hardware. The term “automatic” refers to the sequential tooling indexing and often the bar feeding mechanism, which reduces operator intervention and enables semi-unattended operation during production runs.

Within the broader landscape of lathe machines, small automatic capstan lathes occupy a unique niche. Unlike traditional engine lathes that require skilled operators to manually position tools for each operation, capstan lathes use a rotating turret head to automatically index predetermined tools into position. This systematic approach accelerates production cycles dramatically while maintaining tight tolerances—a combination that makes them particularly valuable for startups, small manufacturing facilities, and specialized toolrooms.

Why small automatic capstan lathes remain relevant in 2025 manufacturing centers on economic pragmatism and production flexibility. CNC lathes, while superior for complex profiles and single-piece customization, demand substantial capital investment, specialized programming knowledge, and longer setup times. Capstan lathes, conversely, excel at producing thousands of identical small parts with minimal setup effort. A workshop producing brass electrical fittings can program a capstan lathe in minutes, then run production for hours with occasional tool changes and coolant monitoring.

The primary use cases for small automatic capstan lathes include mass production of precision small parts (under 50mm diameter), production in toolrooms and job shops, light engineering applications, and situations where automation must remain affordable. Industries ranging from automotive component suppliers to defense contractors utilize these machines for small-scale batch production that falls between traditional hand-turning and full CNC automation.

What Is a Capstan Lathe? (Quick Technical Breakdown)

Definition and Core Principle

A capstan lathe is a semi-automatic turning machine designed for repetitive production of small components using a turret-mounted toolhead that indexes sequentially through multiple cutting operations. The term “capstan” derives from the rotating turret’s resemblance to a ship’s capstan (a rotating post used for winding rope), though modern capstan lathes bear little visual similarity to their nautical namesake.

The core principle behind capstan lathe operation involves mounting multiple cutting tools on a rotating turret, each positioned at a precise distance from the workpiece. As the turret indexes (rotates) between positions, different tools engage the spinning workpiece in predetermined sequence. This systematic tool sequencing eliminates the need for manual repositioning between cuts, dramatically accelerating cycle times compared to engine lathes.

The capstan turret typically holds 6-12 tools simultaneously, though capacity varies by machine size and design. Each turret station can accommodate different tool types—facing tools, parting tools, threading tools, drilling tools—selected specifically for the component being produced. Once the production program is set and tools are installed, the machine can operate with minimal operator involvement.

Capstan vs Turret: The Real Mechanical Difference

While the terms “capstan” and “turret” are often used interchangeably in casual conversation, distinct mechanical differences separate these two lathe types, though modern machines blur these distinctions considerably.

Capstan lathes feature a rotating hexagonal or octagonal turret that positions tooling perpendicular to the lathe spindle axis. The turret mounts on a cross-slide beneath the workpiece, and tools face the rotating bar stock horizontally. Capstan turrets typically employ hydraulic or pneumatic indexing, where the turret rotates to the next tool position automatically during the cycle.

Turret lathes, conversely, traditionally feature a square or rectangular toolpost that rotates vertically or through larger angular increments. The distinction becomes primarily academic with modern machines, as many manufacturers now use “turret lathe” as a catch-all term for any lathe with sequential indexing, regardless of turret geometry.

Practical differences affecting operation:

- Capstan turrets typically index faster due to shorter rotation paths

- Turret lathes often accommodate larger tools and heavier cutting forces

- Capstan lathes generally prove better for smaller parts and tighter tolerances

- Turret lathes traditionally cost slightly more but offer greater production versatility

Capstan vs Engine Lathe vs CNC Lathe: Comparison

| Feature | Small Capstan Lathe | Engine Lathe | CNC Lathe |

|---|---|---|---|

| Setup Time | 15–30 minutes | 20–45 minutes | 30–120 minutes |

| Cycle Time (100 identical parts) | 3–8 seconds per part | 30–90 seconds per part | 5–15 seconds per part |

| Operator Skill Required | Low to moderate | High | Moderate (programming) |

| Initial Machine Cost | $8,000–25,000 | $5,000–15,000 | $35,000–150,000+ |

| Accuracy (±mm) | ±0.05–0.1mm | ±0.1–0.2mm | ±0.01–0.05mm |

| Best for | Repetitive small parts | Custom, varied work | Complex geometry, precision |

| Maintenance Complexity | Low to moderate | Low | Moderate to high |

| Production Flexibility | Moderate | High | High |

| Suitable Batch Sizes | 500–10,000 parts | 1–100 parts | 100–5,000+ parts |

Automatic vs Manual Capstan Lathes

Manual capstan lathes require the operator to manually rotate the turret between tool positions and engage cutting feeds. While this approach reduces machine complexity and cost, it dramatically increases setup time and operator fatigue during long production runs. Manual versions suit small workshops or job shops where production quantities rarely exceed a few hundred parts per week.

Automatic (semi-automatic) capstan lathes feature pneumatic, hydraulic, or electro-mechanical indexing that advances the turret automatically between cuts. Once the cycle begins, the machine advances through tool positions with minimal operator intervention—typically only loading new bar stock and unloading finished parts. This automation reduces operator fatigue, increases consistency, and enables faster production cycles.

Most small automatic capstan lathes encountered in modern workshops are truly semi-automatic, meaning they automate the tool sequencing but still require manual bar loading and part unloading. Fully automatic systems with integrated bar feeders and parts ejection exist but cost considerably more and suit only high-volume production scenarios.

How a Small Automatic Capstan Lathe Works

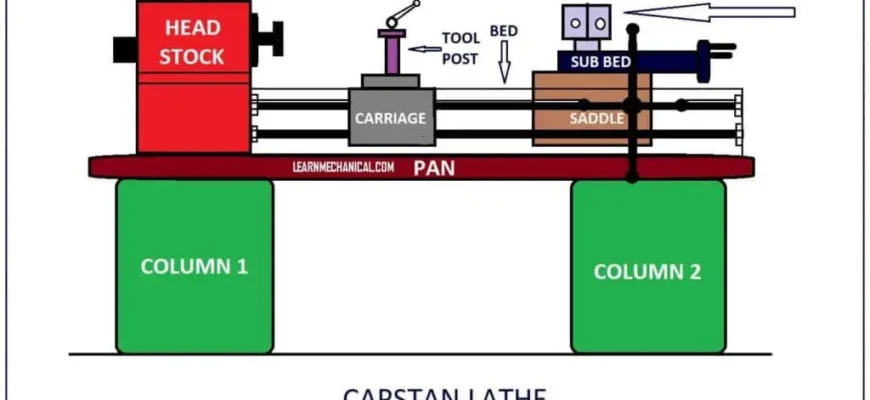

Main Components Explained

Understanding the major mechanical assemblies of a small automatic capstan lathe helps explain why these machines deliver consistent results across thousands of identical parts.

The Capstan/Turret Head: The rotating turret represents the defining feature of a capstan lathe. This multi-sided indexing head (typically hexagonal, octagonal, or round) holds 6-12 cutting tools mounted on separate tool holders. The turret sits below the spindle axis, positioning tools perpendicular to the rotating workpiece. Indexing mechanisms (hydraulic, pneumatic, or mechanical) rotate the turret from one tool position to the next, ensuring precise angular positioning between cycles.

Cross-Slide, Saddle, and Toolpost: The cross-slide moves the turret toward and away from the workpiece, controlling feed depth and tool engagement. The saddle supports the cross-slide and moves along the machine bed, positioning tools along the workpiece length. This assembly must maintain rigidity while permitting smooth, repeatable motion—crucial for consistent part tolerances.

Indexing Mechanism: The indexing system automatically rotates the turret to the next tool position. Hydraulic indexing, common on larger capstan lathes, provides fast, powerful turret advancement. Pneumatic indexing suits smaller machines and delivers adequate speed for most production scenarios. Mechanical indexing (less common on automatic machines) uses cam-driven positioning but operates more slowly.

Bar Feeding System: Bar feeders automatically advance stock material (typically round bar) through the spindle chuck to a predetermined length before each cutting cycle. Manual feeding involves pushing bar stock through the chuck by hand—workable for small shops but tedious during high-volume runs. Automatic feeders mount above or beside the lathe, precisely positioning each new workpiece for repeatable results.

Speed & Feed Controls: Manual capstan lathes employ hand wheels or levers to adjust spindle speed and feed rates. Semi-automatic models typically feature preset controls or simple electronic speed adjustment, allowing operators to optimize conditions for different materials or tool geometries without stopping the machine.

Motor, Spindle, and Chucking Options: Small capstan lathes typically use 1-3 horsepower electric motors driving the spindle through belt or gear reduction. Spindle speeds generally range from 400 to 2500 RPM, though some machines reach 4000+ RPM for aluminum work. Chucking options include three-jaw universal chucks (most common) or collet chucks for precise bar diameter holding.

Step-by-Step Working Cycle

The production cycle on a small automatic capstan lathe follows a logical sequence, repeated hundreds or thousands of times until the batch completes. Understanding this cycle clarifies why capstan lathes achieve such rapid production rates.

Step 1: Bar Stock Feeding

A length of round bar stock (typically brass, aluminum, or mild steel) is either manually inserted into the spindle chuck or automatically fed by the bar feeder. The bar advances to a predetermined stop position, ensuring consistent starting length for every component. This repeatability proves crucial—inconsistent bar positioning creates dimensional variation that degrades part quality.

Step 2: Initial Tool Engagement

The first tool position (typically a roughing tool or facing tool) is already indexed to the working position. As the spindle rotates, this tool engages the bar stock at a preset feed rate. The operator may manually adjust spindle speed or feed depth, though many modern semi-automatic machines feature preset configurations that begin immediately upon cycle initiation.

Step 3: Automatic Turret Indexing

Once the first cutting operation completes (determined by preset depth, time, or mechanical limit switches), the machine automatically indexes the turret to the next tool position. This indexing happens while the spindle remains rotating, though the tool retracts from the workpiece during the rotation period. Indexing typically requires 1-3 seconds, depending on machine type and turret advancement system.

Step 4: Sequential Tool Operations

As the turret rotates through positions, successive tools perform planned operations in sequence: perhaps roughing, finishing, threading, drilling, or grooving. Each tool engages the workpiece for its designated operation, then retracts as the turret indexes to the next position. A skilled setup operator programs this sequence to minimize total cycle time while achieving required tolerances.

Step 5: Parting-Off

The final tool position typically mounts a parting tool, which cuts a groove along the workpiece axis, separating the finished component from the remaining bar stock. This operation must be executed with precision—insufficient depth leaves a small web connecting the part to the bar; excessive cutting risks tool breakage and workpiece deflection.

Step 6: Repetition for Mass Production

Once the finished component falls away from the bar stub, the cycle repeats automatically. New bar stock advances to position, the spindle begins rotation, and the first tool engages again. For typical small parts, cycle times range from 8-20 seconds, meaning a capstan lathe can produce 180-450 identical components per hour with minimal operator attention.

Technical Specifications of Small Automatic Capstan Lathes

Standard Specification Range

Small automatic capstan lathes encompass machines with specifications optimized for light-duty production of components under approximately 50mm in diameter. While specific models vary, these representative specifications illustrate typical capability:

Spindle and Turning Capacity:

- Swing over bed: 100–200mm (3.9–7.9 inches)

- Swing over saddle: 80–150mm (allows tool clearance)

- Spindle bore diameter: 12–25mm

- Maximum bar diameter: 10–20mm

- Maximum bar length: 100–200mm per cycle

Turret and Tooling:

- Turret stations: 6–8 positions (hexagonal or octagonal turret)

- Tool holder capacity: Generally accommodates standard tool holders or custom adaptations

- Turret indexing time: 1–2 seconds (hydraulic or pneumatic)

- Indexing accuracy: ±0.05–0.1mm repeatability

Performance Specifications:

- Spindle speed range: 400–3500 RPM (varies significantly by model)

- Spindle motor horsepower: 1–2.5 HP

- Cutting feed rate: 0.05–0.5mm/revolution (manually adjustable)

- Spindle nose: Typically 4MT (Morse Taper) or direct chuck mounting

Machine Structure:

- Machine weight: 500–1200 kg (light enough for standard industrial floors)

- Floor footprint: Approximately 1.2m × 0.8m × 1.0m (length × width × height)

- Bed material: Cast iron (provides rigidity and vibration dampening)

- Cross-slide travel: 40–80mm perpendicular to spindle axis

- Saddle travel: 150–300mm along machine bed

Automation Options:

- Bar feeder: Manual or automatic pneumatic/hydraulic

- Turret indexing: Manual, pneumatic, or hydraulic

- Coolant system: Manual application or integrated pump circulation

- Emergency stops: Required by modern safety standards

Real-World Specification Examples

Different manufacturers prioritize different capabilities. A bench-top Indian-made capstan lathe (such as ABL or Pathak models) might feature slightly lower spindle speeds but robust turret indexing, while a European precision unit emphasizes tighter tolerances and enhanced control systems.

Types of Small Automatic Capstan Lathes

Bench-Top Compact Capstan Lathes

Bench-top models represent the entry point for workshops adopting capstan lathe technology. These compact machines mount directly on sturdy workbenches, requiring minimal floor space and power infrastructure. Typical specifications include 6-8 turret stations, 100mm spindle swing, and manual or simple pneumatic indexing.

Advantages: Minimal capital outlay ($8,000–15,000), simple maintenance, suitable for job shops and teaching environments, can be relocated within a facility easily.

Limitations: Lower spindle speeds and cutting power restrict material options; limited bar diameter capacity; smaller turret stations accommodate only smaller tool holders; generally manual or semi-manual bar feeding.

Ideal applications: Small precision fasteners, electrical components, watchmaking components, educational demonstrations in technical schools.

Floor-Standing Light-Duty Automatic Capstan Lathes

Floor-standing models (weighing 700–1200kg) provide more substantial spindle power, faster indexing, and integrated bar feeding systems. These semi-automatic machines often feature hydraulic turret indexing for rapid advancement between tool positions, supporting production rates of 300–500 parts per hour for many component types.

Advantages: Faster indexing and production rates, hydraulic bar feeder enables higher automation levels, larger turret stations accommodate diverse tool configurations, greater spindle rigidity supports higher cutting forces.

Limitations: Higher capital cost ($15,000–35,000), increased floor space requirements, more complex maintenance procedures, skilled setup work essential for productivity optimization.

Ideal applications: Brass fittings production, small auto parts manufacturing, defense contractor small parts, high-volume fastener production, production job shops.

Semi-Automatic Capstan Lathes

Semi-automatic models automate specific functions (tool indexing, bar feeding) while leaving others to operator control. This hybrid approach balances automation benefits with flexibility and lower cost than fully automatic systems.

Characteristic features:

- Automatic turret indexing via pneumatic or hydraulic actuation

- Manual or simple automatic bar feeding

- Operator controls spindle speed and feed engagement

- Typically 1–2 HP motors with modest spindle speeds

- 6–8 turret tool positions

Ideal for: Job shops performing multiple different components weekly, training environments, small workshops with limited production volumes, facilities requiring production flexibility.

Hydraulic & Pneumatic Indexing Capstan Lathes

The indexing mechanism profoundly affects production efficiency. Hydraulic indexing enables rapid, powerful turret advancement (0.5–1.5 seconds per index), supporting production of larger, more demanding components. Pneumatic indexing delivers moderate speed (1–3 seconds per index) at lower cost and with simpler maintenance requirements.

Hydraulic systems generally appear on larger, higher-production machines where cycle time savings justify the added complexity. Pneumatic indexing suits smaller machines and shops prioritizing simplicity over maximum production rate.

Micro-Capstan Lathes for Watchmaking & Micro-Components

Specialized micro-capstan lathes serve precision industries requiring components under 10mm diameter with exceptionally tight tolerances. These machines feature enhanced spindle bearings, precision chuck systems, and sensitive feed controls enabling tolerance achievement within ±0.01mm.

Applications: Watchmaking components (balance wheels, pivots, gear shafts), medical device miniature parts, precision instrument components, jewelry manufacturing components.

Cost consideration: Micro-capstan lathes command premium pricing ($20,000–50,000+) due to enhanced precision and specialized construction. Purchasing used micro-capstan equipment offers cost savings for smaller operators.

Materials & Applications

Suitable Materials for Capstan Lathe Production

Small automatic capstan lathes excel at machining materials offering good machinability at modest cutting speeds, where tool cost and production rate remain competitive with alternative manufacturing methods.

Brass and Brass Alloys: The preferred capstan lathe material, brass machines cleanly at high speeds, produces excellent surface finishes, and generates easily managed swarf (metal chips). Free-cutting brass varieties (containing lead or bismuth) deliver optimal results, though lead-free environmental specifications now dominate new material selections. Typical production rates reach 10–20 components per minute for simple brass fittings.

Mild Steel and Carbon Steel: Mild steel (low carbon content) machines readily on capstan lathes at moderate speeds, though tool wear accelerates compared to brass production. Hard steels demand lower speeds and more frequent tool changes, reducing productivity. Steel production suits high-volume runs where tool wear costs distribute across many parts.

Aluminum and Aluminum Alloys: Aluminum’s low density and excellent machinability make it attractive for capstan production, particularly for aerospace and automotive applications. Aluminum machines at very high speeds (1500–3500 RPM typical), but requires careful coolant management to prevent chip welding to tools. Aluminum’s softness sometimes produces stringy chips that tangle in the machine, requiring operator attention.

Stainless Steel (Limited): Stainless steel’s excellent corrosion resistance comes at the cost of poor machinability. The material work-hardens during cutting, causing rapid tool wear and requiring slower speeds than mild steel. While capstan lathes can process stainless steel, production rates drop 50-70% compared to brass, and tool costs increase dramatically. Most workshops reserve stainless steel work for CNC lathes or specialized automatic machines designed specifically for difficult-to-machine materials.

Copper Alloys: Phosphor bronze and other copper alloys combine excellent machinability with corrosion resistance. Production rates rival brass for many copper alloys, making them economical choices for capstan lathe work despite higher material costs.

Plastics and Polymers: Acrylic, nylon, and delrin (acetal copolymer) machine well on capstan lathes, often at higher speeds than metals. Plastic production benefits from the capstan’s rapid indexing and light cutting forces, though tool geometry differs from metal-cutting setups. Plastic’s tendency to melt during cutting requires attention to speed optimization and coolant strategy.

Industries Using Small Automatic Capstan Lathes

Automotive Component Manufacturing: Small auto parts suppliers utilize capstan lathes for starter motor shafts, alternator components, fuel injector bodies, and brake system fittings. Automotive OEM (original equipment manufacturer) tier suppliers often operate dedicated capstan lathe cells producing specific components in volumes of 10,000–50,000 units monthly.

Precision Instrument Manufacturing: Scientific instruments, optical equipment, and precision measuring devices require small, accurately machined components. Capstan lathes produce lens mounting threads, precision optical bench bases, and instrument calibration shafts economically at volumes between manual production and CNC automation.

Electrical Fittings and Components: Electrical connectors, terminal blocks, and circuit breaker components represent classic capstan lathe products. The high repeatability and tight tolerance capability make capstan lathes ideal for this sector, where thousands of identical components must meet strict electrical safety standards.

Plumbing Hardware: Faucet bodies, valve components, and brass tubing fittings emerge from capstan lathes continuously. Brass’s machinability and the components’ dimensional consistency requirements align perfectly with capstan lathe capabilities.

Fasteners and Threaded Components: Bolts, screws, studs, and nuts require automatic production at high volumes. While dedicated fastener-making equipment exists, small capstan lathes handle prototype and low-volume fastener production effectively, particularly for specialized grades or custom specifications.

Defense and Aerospace Small Parts: Defense contractors and aerospace suppliers employ capstan lathes for producing small structural and mechanical components, hydraulic system fittings, and instrument mounting brackets. The repeatability and precision justify the labor costs associated with setup and tooling.

Medical Device Manufacturing: Surgical instrument components, diagnostic device precision parts, and implant subassemblies often originate from capstan lathes, where tolerance and repeatability requirements exceed manual capabilities but volumes don’t justify CNC investment.

Small Automatic Capstan Lathe vs Similar Machines

Capstan Lathe vs Turret Lathe: Deep Comparison

While modern usage often treats these terms synonymously, traditional capstan and turret lathes maintain distinct characteristics affecting suitability for different production scenarios.

Production Speed Comparison:

Capstan lathes generally achieve faster cycle times (8–15 seconds) for small components due to rapid hexagonal turret indexing and optimized tool positioning perpendicular to the spindle. Traditional turret lathes, with larger rectangular turrets and angular positioning, typically require 15–25 seconds per cycle for comparable work. This 30-50% speed advantage makes capstan lathes preferable for high-volume small-part production.

Capacity Differences:

Turret lathes traditionally accommodate larger bar diameters (up to 100mm or more) and heavier cutting forces, making them suitable for producing medium-sized components. Capstan lathes, optimized for small parts (10–20mm diameter), sacrifice capacity for speed and precision. A workshop producing components ranging from 5mm to 50mm diameter requires multiple machine types or accepts compromises on production efficiency.

Setup Time Implications:

Both machine types require tool selection, mounting, and positioning before production begins. Capstan setup typically requires 15–30 minutes for a new component, while turret lathes might need 30–45 minutes due to larger tool positioning requirements. Subsequent tool changes during a run prove faster on capstan machines due to simpler indexing sequences.

Tooling and Turret Construction:

Capstan turrets mount tools perpendicular to the spindle axis in a compact hexagonal or octagonal geometry. Turret lathes traditionally position tools more vertically, accommodating heavier, larger tool holders. This geometric difference fundamentally affects how tools can approach the workpiece and what cutting operations become practical.

Capstan Lathe vs Automatic Lathe vs CNC Lathe: Production Scenario Comparison

Selecting the optimal machine type requires understanding how accuracy requirements, batch size, component complexity, and production volume interact:

For 500-part orders of simple brass fittings: A small automatic capstan lathe excels. Setup requires 20 minutes, cycle time runs 10 seconds, and total production completes in roughly 1.5 hours. A CNC lathe would require 60–90 minutes of programming plus 45 minutes of production—not economical for this volume. An automatic lathe (dedicated fastener equipment) doesn’t justify cost for this order size.

For 5,000-part orders of threaded steel components: The capstan lathe remains economical if tolerance requirements stay within ±0.1mm. If tolerances tighten to ±0.05mm or component geometry becomes complex, a CNC lathe’s superior accuracy justifies its higher production cost through fewer scrap parts and simpler tool changes.

For ongoing production of 50,000+ parts monthly: A dedicated automatic machine (if the component justifies the investment) or multiple CNC lathes running in parallel often surpass capstan efficiency through labor reduction and increased uptime from simplified tool wear management.

For custom prototyping or 1–100 part orders: Engine lathes or small CNC machines provide flexibility capstan lathes sacrifice. Capstan machine setup time, meaningful only when amortized across hundreds of identical parts, becomes punitive for custom work.

Key Features to Look For (Buyer’s Checklist)

When evaluating small automatic capstan lathe purchases, several critical features directly impact long-term productivity and part quality:

Turret Indexing Accuracy

Indexing precision determines whether the turret positions tools consistently from cycle to cycle, directly affecting dimensional consistency of produced parts. Look for machines specifying ±0.05mm or better indexing repeatability. Test indexing on demo machines by comparing successive tool positions with dial indicators—variations exceeding 0.1mm suggest mechanical wear or inadequate indexing system design.

Hydraulic indexing systems generally maintain tighter accuracy than pneumatic systems, though properly maintained pneumatic machines can satisfy most production requirements. Inspect hydraulic systems for leakage; even small leaks degrade indexing consistency progressively.

Ease of Tool Change

During extended production runs, tool wear necessitates replacement without stopping the machine or redoing setup. Superior machines feature quick-change tool holders (standardized across all turret positions) enabling tool swaps in 2–3 minutes without re-alignment. Machines requiring tool realignment after changes increase downtime and production costs.

Test tool change procedures on demo machines. Quick-change systems should enable tool installation and removal one-handed, with automatic centering upon installation. Tools should seat with consistent pressure, eliminating manual adjustment requirements.

Bar Feeding Mechanism

Manual bar feeding (operator pushes bar through chuck to a stop position) suits shops where production volumes stay modest (under 500 parts daily). Pneumatic or hydraulic bar feeders automate this process, enabling semi-unattended operation during production runs and dramatically increasing daily capacity.

For regular production exceeding 1,000 parts daily, automatic bar feeding justifies the added cost and complexity. Inspect feeder mechanisms for smooth operation and positive bar positioning—inconsistent feeder performance directly translates to dimensional variation in finished parts.

Rigidity of Bed and Saddle

Machines producing parts within close tolerances require substantial rigidity. Cast iron beds and saddles dampen vibration and maintain dimensional stability across thousands of cutting cycles. Inspect bed surfaces with straightedges, looking for warping (common on older machines). Test saddle movement by applying modest manual force—excessive play or binding indicates worn ways requiring professional restoration.

Machine weight correlates with rigidity; machines under 600kg may prove insufficiently rigid for production below ±0.05mm tolerances or aggressive cutting parameters. Heavier machines (800kg+) typically maintain tighter tolerances across extended production runs.

Maintenance Access

Well-designed capstan lathes position lubrication points, adjustment mechanisms, and wear components accessibly. Poor access designs force mechanics to remove components or contort themselves into uncomfortable positions, increasing maintenance time and creating opportunities for errors.

Inspect machines for clearly marked lubrication points, easily removable covers accessing spindle bearings and turret indexing mechanisms, and tool access enabling turret removal without complete machine teardown.

Safety Features

Modern machines must include emergency stop buttons (large red buttons interrupting power immediately), protective guards preventing hand access to rotating spindle and turret, and chip evacuation covers preventing chip ejection toward operators.

Older machines may lack these safety features; retrofitting proper guards and emergency stops adds cost but proves essential for legal compliance and worker safety. Verify emergency stop functionality—they should cut all rotating motion immediately without coasting.

Included Standard Accessories

Evaluate what accessories accompany the machine: collets or chuck jaws, basic tool holders, coolant pump and nozzles, basic wrench set for turret tool changes, instruction manuals, and spare parts kit recommendations. Reputable manufacturers bundle essential accessories; machines sold bare require additional expenditures before production begins.

Warranty and After-Sales Support

New machines should include 1–2 year manufacturer’s warranty covering mechanical defects and indexing consistency. Used machines typically offer no warranty but may include operator training or installation assistance from sellers.

Verify availability of replacement parts (spindle bearings, turret seals, chuck jaws) for your specific model. Machines with proprietary components become expensive to maintain long-term if manufacturers cease parts production.

Advantages of Small Automatic Capstan Lathes

Fast Cycle Time for Repeated Components

The defining advantage of capstan lathe technology, rapid cycle times result from sequential tool indexing and optimized component positioning. Small brass fittings cycle in 8–12 seconds; steel components requiring more aggressive machining might cycle in 15–20 seconds. Achieving similar results on manual lathes requires 60–120 seconds per component, meaning capstan lathes accelerate production 5–10 times for simple parts.

This speed advantage compresses manufacturing timelines dramatically. A 500-part order requiring 8 hours on manual lathes completes in 1.5 hours on a capstan machine, enabling faster order fulfillment and improved cash flow for shops operating on tight schedules.

Low Skill Barrier

Unlike traditional lathe operation—requiring months or years to develop feel for feeds, speeds, and tool geometry—capstan lathe operation becomes teachable to less experienced workers after modest training. Once setup specialists program the tool sequence and set initial parameters, operators require only the ability to load bar stock, engage the cycle, and unload finished parts.

This accessibility dramatically expands the potential labor pool, enabling small shops to remain competitive without recruiting highly skilled machinists who command premium wages. Operator wages for capstan work typically run 20–30% below traditional lathe operators, directly improving bottom-line profitability.

High Repeatability

A properly set-up capstan lathe produces parts with dimensional consistency difficult to achieve on manual machines, where operator technique variation creates inconsistency. The first component produced on a capstan lathe closely matches the 5,000th, enabling customers to specify tight tolerances without receiving batches containing dimensional scatter.

This repeatability proves especially valuable for components feeding into assembly operations or applications with dimensional stack-ups where scatter in individual components accumulates into assembly problems.

Small Footprint

A typical small capstan lathe occupies floor space under 1.5 square meters—less than many manual engine lathes. This compact footprint enables workshops to fit additional capstan machines in existing facilities, exponentially increasing production capacity without facility expansion.

Bench-top models occupy even less space, functioning on sturdy workbenches and enabling workshops to add production capacity literally on existing surfaces without construction modifications.

Lower Cost Than CNC

CNC lathes require investments 3–5 times higher than small automatic capstan lathes for equivalent spindle capacity. A budget CNC lathe starts around $35,000; a quality small capstan lathe costs $15,000–25,000. This capital savings enables workshops to purchase multiple capstan machines for less than a single CNC system, providing production redundancy and the ability to run different components simultaneously.

For shops processing production orders under 5,000 parts, CNC’s superior flexibility doesn’t justify its capital and programming overhead. Capstan economics dominate this production volume sector entirely.

Ideal for Startups and Small Workshops

Budding manufacturing entrepreneurs or established small workshops seeking production capacity expansion find capstan lathes uniquely suited to their circumstances. The modest capital requirements, straightforward operation, and rapid return on investment through production acceleration make capstan machines the logical first production machine for emerging manufacturers.

Limitations to Consider

Not Ideal for Complex Profiles

Capstan lathes excel at producing components requiring sequential simple operations: facing, drilling, threading, parting. Complex contoured profiles, offset hole patterns, or curved surfaces demand manual repositioning on traditional capstan lathes—the efficiency advantage evaporates.

CNC lathes can produce complex profiles in single setups, making them inherently superior for sophisticated component geometry. A component requiring multiple manual tool repositionings on a capstan lathe might complete faster on a properly programmed CNC.

Lower Precision Than CNC

While capstan lathes maintain excellent repeatability for simple operations, absolute accuracy potential remains limited by indexing system tolerances and spindle bearing wear accumulation. Achieving tolerances tighter than ±0.05mm proves challenging on typical capstan machines, whereas CNC systems routinely hold ±0.01mm or better.

This accuracy limitation matters little for many fasteners and fittings, where ±0.1–0.2mm tolerances satisfy functional requirements. Components requiring laser-tight tolerances (optical components, precision instruments) demand CNC capabilities.

Limited Bar Stock Diameter

Small capstan lathes handle bar diameters up to approximately 20mm effectively; larger diameters push spindle power and chuck capacity limits. Manufacturers requiring components from 30–50mm diameter bar must upgrade to medium capstan lathes or alternative machines.

This diameter limitation doesn’t constitute a problem for producers of small fasteners, electrical components, or plumbing hardware—categories where components inherently emerge from small-diameter bar stock.

Higher Wear-and-Tear on Indexing Mechanisms

Automatic indexing mechanisms experience wear through millions of index cycles across years of operation. Hydraulic indexing systems develop seal leaks gradually; pneumatic systems require regular air filter maintenance to prevent contaminant introduction to indexing actuators.

This wear mandates periodic maintenance and eventual component replacement—preventive maintenance that some workshops overlook until indexing accuracy degrades visibly. Budget for eventual turret actuator rebuilding or replacement during the machine’s operational lifetime.

Setup, Operation & Safety

Installation Requirements

Power Supply: Small capstan lathes typically consume 1.5–3 kilowatts during normal operation, with peak power draw during spindle acceleration. Three-phase power (common in industrial facilities) works optimally; single-phase operation requires phase converters or variable frequency drives (adding cost and reducing efficiency).

Verify facility power availability before purchase. Facilities lacking three-phase service should negotiate power installation as part of machine purchase, factoring installation costs into acquisition decisions.

Foundation and Leveling: Proper machine leveling profoundly affects spindle performance and dimensional accuracy. Concrete floors require shimming with precision shim stock, not wood or metal bars. After positioning machines on level flooring, verify levelness with precision levels and allow concrete setting time (24–48 hours) before full production operation.

Machines installed on uneven floors develop spindle run-out (wobble), degrading surface finish and tolerances dramatically. Unlevel installations also cause indexing mechanism binding and accelerated wear.

Lubrication System: Modern capstan lathes feature sealed spindle bearings requiring minimal maintenance, but indexing mechanisms, cross-slide ways, and spindle nose require regular lubrication. Establish lubrication schedules according to manufacturer specifications—typically weekly light oiling of ways and daily or every-few-cycles indexing mechanism lubrication.

Automated lubrication systems (grease or oil circulation) benefit high-production facilities; manual lubrication suffices for job shops making 500–1,000 parts daily.

Operating Tips

Turret Alignment: Ensure turret tool positions align concentrically with the spindle axis. Misaligned turrets cause progressive dimensional errors as the run progresses. Check alignment monthly using test indicators and adjust if drift exceeds 0.05mm.

Tool Pre-Setting: Establish precise initial tool engagement depth before beginning production. Off-setting initial tools causes the first cycle to produce parts differing from subsequent cycles. Use precision edge finders or comparators to establish reference surfaces, then position each tool relative to these references.

Coolant Optimization: The specific cutting fluid appropriate for the material (brass, steel, aluminum) dramatically affects tool life and surface finish. Select coolant matching the material being machined—brass coolant differs significantly from steel coolant in cooling and lubrication properties. Monitor coolant concentration (typically 5–10% concentrate in water) and replace when degradation becomes visible through increased tool wear or surface finish deterioration.

Safety Guidelines

PPE (Personal Protective Equipment): Operators require protective eyewear (polycarbonate lenses withstanding chip impact), hearing protection (capstan lathes generate 85+ decibels), and close-fitting clothing without loose sleeves or jewelry that might catch in rotating machinery.

Steel-toed boots protect against dropped components; cut-resistant gloves aid handling sharp chip swarf safely. Long hair must be tied back completely—loose hair’s entanglement in rotating spindles causes serious injuries.

Handling Rotating Bar Stock: The primary hazard in capstan lathe operation comes from rotating bar stock extending from the spindle chuck. Never reach toward spinning bar stock while the spindle rotates. Use chip hooks or brushes to clear chips away from the spinning work, maintaining safe distance.

Before loading or unloading work, verify the spindle has stopped completely. A spindle appearing stopped may still possess residual rotation from inertia; wait 3–5 seconds after turning off the spindle before approaching the chuck area.

Emergency Stops and Guards: Verify emergency stop buttons function before each production session by activating them during idle conditions. Guards protecting the spindle and turret should remain in place during operation, removed only for tool changes or maintenance.

Many industrial accidents result from operators disabling or removing guards for convenience—establishing workplace culture emphasizing safety dramatically reduces injury likelihood. Regular safety briefings and injury prevention discussions keep safety awareness high.

Maintenance and Troubleshooting Guide

Daily Inspection

Begin each production shift with visual inspection of the machine in its pre-startup state. Check for fluid leaks beneath the machine (suggesting failing seals or line ruptures), listen for unusual grinding or squealing sounds (indicating bearing problems or misalignment), and verify all guards remain in place and operational.

Spin the spindle by hand (with power off) to verify smooth, consistent rotation without resistance. Gritty or grinding sensations suggest bearing problems requiring investigation before starting production.

Lubrication Points and Schedule

Spindle Bearings: Most modern capstan lathes feature sealed spindle bearings requiring no regular lubrication. Verify bearing condition by listening for growling sounds or feeling for temperature spikes during operation—indicators of bearing degradation.

Turret Indexing Mechanism: Pneumatic indexing systems require light oil or grease lubrication of cylinders and linkages. Apply lubricant according to manufacturer specifications (typically every 100–200 index cycles for high-production facilities). Dried-out linkages develop sluggish indexing and inconsistent positioning.

Cross-Slide Ways: Light machine oil applied weekly to cross-slide ways maintains smooth motion and prevents rust formation on cast iron surfaces. Apply oil sparingly—excessive lubrication attracts dust and metal chips, creating thick sludge impairing slide smoothness.

Spindle Nose and Chuck: Monthly cleaning and light oiling of spindle nose threads and chuck mating surfaces prevents corrosion and ensures consistent workpiece seating. Use a brass brush to clean accumulated chips and mineral deposits before applying fresh oil.

Turret Indexing Issues

Sluggish indexing: If turret advancement slows relative to normal operation, check pneumatic or hydraulic pressure supply. Pressure drops indicate supply line blockages, failed compressor output, or pump degradation. Replace air filters in pneumatic systems monthly in dirty environments.

Inconsistent indexing position: Indexing positions varying cycle-to-cycle suggest positioning pin wear or hydraulic/pneumatic system irregularities. Test by running empty cycles (without tools engaged) and measuring positioning deviation with dial indicators. Deviation exceeding 0.1mm warrants professional inspection or component replacement.

Indexing mechanism won’t advance: Complete indexing failure indicates power supply loss to pneumatic/hydraulic actuators, linkage breakage, or actuator failure. Check power supply first; verify control switches engage correctly. If power reaches actuators but mechanism doesn’t advance, internal seal failure or actuator damage likely requires professional service.

Cross-Slide Backlash

Excessive play in the cross-slide (tool moving independently when feed engagement disengages) causes dimensional inconsistency—the first component produced differs from subsequent ones as the machine finds its operating position. Backlash develops through worn leadscrew nuts or misaligned ways.

Test backlash by engaging a dial indicator against the toolpost and manually advancing the cross-slide through its range while observing indicator. Backlash exceeding 0.05mm requires adjustment or component replacement. Many machines feature adjustable gibs (wedge-shaped components pressing wear surfaces into proper contact) enabling mechanics to reduce backlash through careful adjustment.

Spindle Vibration Diagnostics

Spindle vibration manifests as wavy surface finishes or squealing sounds. Causes include spindle bearing damage, unbalanced chucks with concentrically-mounted workpieces, bent spindle shafts, or misaligned spindle pulleys.

Test spindle run-out using precision indicators while the spindle rotates at normal production speed. Run-out exceeding 0.05mm indicates bearing wear or shaft damage requiring professional servicing. Clean and re-balance chucks before assuming bearing failure—accumulated chips inside chuck jaws often cause apparent vibration.

Price Guide: How Much Does a Small Automatic Capstan Lathe Cost?

New Machine Price Ranges

Entry-level bench-top models (India/Asia manufacturing):

- Range: $8,000–15,000 USD

- Typical suppliers: ABL Machines, Pathak Industries, Kabir Machine Tools

- Specifications: 100mm swing, 6-8 turret stations, manual indexing or basic pneumatic

- Suited for: Job shops, training facilities, small contract manufacturers

Mid-range floor-standing semi-automatic models:

- Range: $15,000–30,000 USD

- Typical suppliers: Indian manufacturers (HMT heritage designs), Chinese Hoston-branded machines

- Specifications: 150–200mm swing, hydraulic indexing, optional bar feeder, 1–2 HP motors

- Suited for: Established small manufacturers, high-volume production (1,000+ parts daily)

Premium European or precision-focused models:

- Range: $30,000–50,000+ USD

- Typical suppliers: Swiss, Italian, or German precision equipment manufacturers

- Specifications: Enhanced precision (±0.05mm indexing), superior spindle bearings, advanced control systems

- Suited for: Precision production, aerospace/defense contractors, micro-component manufacturers

Micro-capstan lathes (watchmaking, micro-components):

- Range: $35,000–75,000 USD

- Typical suppliers: Specialized Swiss or precision equipment houses

- Specifications: Sub-10mm component capacity, ±0.01mm repeatability, specialized tooling

- Suited for: Watch parts manufacturers, medical device producers, precision instrument makers

Used Machine Price Overview

Quality used capstan lathes often represent exceptional value for budget-conscious shops, though mechanical condition assessment proves crucial:

Machines 5–10 years old (excellent condition): 50–65% of equivalent new machine pricing

Machines 10–20 years old (good operating condition): 35–50% of new pricing

Machines 20+ years old (serviceable condition): 20–35% of new pricing

Price premiums exist for specific model reputations (Indian HMT heritage machines generally hold value well; some Chinese machines show lower demand in used markets) and for machines with low hour counts (under 5,000 operational hours) compared to high-hour industrial machines.

Inspection and testing before purchase prove essential. Have a qualified machinist inspect used machines, test turret indexing accuracy, and verify spindle bearing condition—defects discovered after purchase become expensive to remedy. Budget $500–1,500 for professional inspection, shipping, and installation when purchasing used equipment.

Cost of Tooling and Accessories

Beyond the machine itself, operators must budget for:

Initial tool set (6–8 tool holders matching machine turrets): $800–2,000 depending on precision requirements

Cutting tools (inserts, drills, threading tools): $500–1,500 for initial variety; ongoing $100–300 monthly depending on production volume and material toughness

Collets or additional chuck jaws: $200–600 to enable working with multiple bar diameters

Coolant system (pump, hoses, nozzles): $300–800 for integrated systems; manual application requires minimal cost

Safety equipment and guards: $400–1,000 for retrofit guards if upgrading older machines

Spare parts reserve (spindle seals, turret actuator seals, bearing replacements): Budget $100–200 monthly during the machine’s first 3–5 years until understanding typical failure patterns

Budgeting for Maintenance

Establish maintenance budgets based on production intensity:

Light production (500–1,000 parts weekly): $100–200 monthly for lubrication, filter replacement, and wear item stocking

Medium production (2,000–5,000 parts weekly): $300–600 monthly for more frequent component replacements and professional servicing

High production (10,000+ parts weekly): $800–1,500 monthly for preventive maintenance contracts and rapid wear component stockpiles

Plan for major rebuilds every 15,000–20,000 operational hours (typically 5–7 years at normal production levels), budgeting $2,000–5,000 for professional spindle bearing replacement, turret actuator restoration, and way surface restoration.

Top Manufacturers and Models: Global and India

India: Established and Respected Capstan Lathe Producers

ABL Machines (Indian manufacturer): ABL has produced quality capstan lathes for decades, with models ranging from bench-top 100mm swing machines ($10,000–12,000) to medium-capacity floor-standing units ($18,000–25,000). Indian buyers favor ABL machines for their robust construction, availability of spare parts across India, and established service networks in major industrial cities.

Pathak Industries: Pathak specializes in capstan and turret lathe variants, offering both manual and semi-automatic indexing models. Pathak bench-top models ($9,000–13,000) prove popular in small job shops. The company maintains strong presence in Mumbai, Pune, and Bangalore industrial regions.

Kabir Machine Tools: Kabir produces mid-range capstan machines emphasizing hydraulic indexing and integrated bar feeding. Their models ($15,000–28,000) appeal to manufacturers seeking higher production rates while maintaining affordability compared to European precision equipment.

HMT Heritage Designs: Many Indian manufacturers produce designs inheriting from HMT (Hindustan Machine Tools), the government-operated enterprise that dominated Indian machine tool manufacturing. These machines provide excellent value in used markets ($3,000–8,000 for machines 15–30 years old) and represent accessible entry points for newcomers to capstan lathe production despite potential component obsolescence challenges.

China: Affordable Production-Focused Options

Hoston Machine Tools: Hoston produces budget-conscious capstan lathes optimized for high-volume production. Models typically feature pneumatic indexing, simple control systems, and pricing 15–30% below equivalent Indian machines. Hoston machines prove suitable for production-focused operations less concerned with long-term parts availability.

Slant-bed Automatic Variants: Several Chinese manufacturers produce slant-bed capstan configurations (bed angles 25–45 degrees) improving chip evacuation and operator ergonomics. These variants cost $2,000–5,000 more than conventional horizontal-bed models but increase operator comfort during extended production runs.

Europe: Premium Precision-Focused Equipment

Swiss precision manufacturers: Companies like Tornos and Citizen (Japan-based, European plants) produce premium small automatic lathes emphasizing exceptional precision (±0.01–0.02mm repeatability) and superior spindle bearing quality. These machines ($40,000–100,000+) represent ultimate accuracy capability but primarily suit micro-component production and precision instrument manufacturing rather than general small-parts manufacturing.

Italian and German Heritage Machines: Older European capstan and turret lathes (20–40 years old) often exhibit exceptional build quality and remain serviceable long-term despite age. Used European machines frequently appear in Indian and Middle Eastern markets at $5,000–15,000, providing premium quality at moderate pricing compared to new equivalents.

Small Automatic Capstan Lathe: Real-World Case Studies

Case Study 1: Workshop Producing Brass Electrical Fittings

Workshop Profile: A small electrical components manufacturer in Mumbai operated a single manual lathe producing brass terminal blocks and connector bodies. Production bottleneck occurred consistently—orders requiring 2,000 identical components took 4 weeks to produce, limiting business growth.

Problem Identified: Manual lathe operation required 45–60 seconds per component including tool positioning, engagement, and manual cycling. The operator’s wage represented a significant cost per piece, and maintaining tolerance consistency across 2,000 identical parts proved difficult.

Solution Implemented: The workshop purchased an ABL bench-top capstan lathe ($12,000) with 6-station turret, pneumatic indexing, and manual bar feeding. Production setup required careful tool sequencing and initial parameter testing—a 2-day process for the first component type.

Results Achieved:

- Cycle time reduced from 50 seconds to 12 seconds per component (75% improvement)

- Production now completed 2,000 components in 5 working days

- Operator skill requirement decreased significantly; training new operators took days rather than months

- Part consistency improved dramatically; customer return rates for dimensional issues dropped from 2% to 0.1%

- Equipment paid for itself through increased production within 8 months

Key Lesson: The capstan lathe’s real value emerged through production velocity combined with consistency—the combination proving impossible on manual equipment. The workshop now reserves the original manual lathe for prototype development and one-off custom work while capstan handles volume production.

Case Study 2: Auto Parts Small-Scale Mass Production

Operation Context: An Indian automotive tier-2 supplier produces alternator shafts, starter motor components, and fuel injector bodies—components requiring production volumes of 5,000–15,000 units monthly at tight tolerances (±0.05–0.08mm).

Equipment Configuration: The supplier operates a cell containing three floor-standing capstan lathes with hydraulic indexing, integrated bar feeders, and coordinated with a small CNC lathe for specialized components. The three capstan machines operate simultaneously, with one operator monitoring all three machines while a second operator handles bar loading and chip management.

Production Efficiency:

- Three capstan lathes collectively produce 8,000–12,000 components daily

- CNC lathe handles specialty components comprising 5–10% of monthly volume

- Operator labor costs per component run 60% below equivalent CNC production

- Equipment utilization remains high (16 productive hours daily across two shifts)

Maintenance Strategy: Preventive maintenance contracts with local machine service providers ensure rapid resolution of indexing mechanism issues or spindle bearing problems. The supplier budgets $1,200 monthly for maintenance and spare parts stocking.

Key Lesson: Multiple capstan machines operating in coordinated production cells deliver high throughput at capital costs significantly below equivalent CNC production. The strategy proves especially effective for automotive tier suppliers producing moderate volumes with repetitive component geometry.

Case Study 3: Microfabrication Unit Producing Precision Components

Specialization: A precision component maker produces watchmaking parts, medical device subassemblies, and optical instrument components—items requiring tolerances under ±0.02mm and component sizes under 15mm diameter.

Equipment Selection: The firm operates two micro-capstan lathes ($45,000 each) with enhanced spindle bearing precision, precision chuck systems, and refined tool positioning accuracy. These machines exceed standard capstan capability and represent substantial investment.

Production Characteristics:

- Cycle times range 20–40 seconds per component depending on geometry complexity

- Tool wear necessitates replacement every 5–10 hours of production (compared to 40–100 hours on standard capstan work)

- Operator training requires 2–3 months to develop competency at this precision level

- Components achieve consistency enabling direct assembly without post-production sorting

Critical Success Factor: Rigorous tool pre-setting procedures (consuming 1–2 hours per new component type) establish reference points enabling rapid indexing cycle repeatability. Without this precision infrastructure, the expensive micro-capstan equipment produces no better results than standard machines.

Key Lesson: Micro-component production justifies premium equipment investment only when complemented by equally rigorous setup and maintenance procedures. The equipment represents necessary but not sufficient condition for precision manufacturing success.

FAQs

Q: What is the main difference between a capstan and a turret lathe?

A: The primary distinction lies in turret geometry and tool positioning. Capstan lathes feature compact hexagonal or octagonal turrets positioning tools perpendicular to the spindle axis, optimized for rapid indexing and small-component production. Turret lathes traditionally employ larger, often square turrets positioning tools at different angles, accommodating heavier cutting forces and larger components. Modern terminology sometimes uses these terms interchangeably, but traditional capstan lathes achieve faster cycle times for small parts while turret lathes handle larger work better. Understanding your specific production needs—component size, complexity, and volume—guides equipment selection more than terminology distinctions.

Q: Is a capstan lathe automatic?

A: Small automatic capstan lathes feature sequential turret indexing that progresses automatically through tool positions without operator intervention. However, they remain only “semi-automatic” in full production context—operators manually load bar stock into the chuck and remove finished components. Bar feeders exist for automating stock advancement, but most small shop capstan lathes require operator engagement during loading and unloading. Fully automatic systems with integrated bar feeders and parts ejection exist but cost significantly more and suit only very high-volume dedicated production scenarios (50,000+ identical parts monthly).

Q: What is the function of the capstan head?

A: The capstan head (rotating turret) holds 6–12 cutting tools in predetermined positions around a central axis. During operation, the turret rotates (indexes) to position successive tools perpendicular to the workpiece, enabling rapid tool changes without manual repositioning. Each tool engages the spinning workpiece for its designated operation, then retracts as the turret indexes to the next position. This systematic tool sequencing represents capstan lathes’ defining characteristic—enabling rapid production of identical small components through automatic tool progression rather than manual tool repositioning.

Q: Can capstan lathes replace CNC machines?

A: Capstan lathes excel at repetitive production of simple small components and represent ideal replacements for manual lathe work where production volumes justify semi-automation. However, they cannot fully replace CNC machines for applications requiring complex geometry, tight tolerances (under ±0.02mm), or frequent design changes. CNC’s superior accuracy and geometric flexibility prove necessary for precision instrument work and components demanding sophisticated profiles. The optimal strategy involves both technologies—capstan machines for high-volume simple components, CNC for complex custom work—since each technology dominates its specific application range.

Q: What bar diameter can small capstan lathes handle?

A: Small automatic capstan lathes typically handle bar diameters from 5mm to 20mm, with 8–16mm representing the most common working range. Spindle bore diameter (typically 12–25mm) and chuck capacity determine maximum bar size. Attempting to machine oversized bar stock risks spindle damage and chuck fracture. If production requirements involve bar diameters exceeding 20mm, investigate medium-capacity capstan lathes (offering up to 30–50mm bar capacity) or alternative machine types entirely. The bar size limitation matters little for typical capstan applications (fasteners, electrical fittings, plumbing hardware) where components inherently emerge from small-diameter stock.

Q: How does turret indexing accuracy affect production quality?

A: Indexing accuracy directly determines dimensional consistency across production runs. Accurate indexing (±0.05mm or better) ensures tools position consistently, producing parts with minimal scatter. Poor indexing (variations exceeding 0.1mm) causes dimensional variation as the turret positions tools at slightly different distances from the spindle in successive cycles. For simple components with generous tolerances (±0.2mm or greater), modest indexing variation matters little. Precision work requiring ±0.05mm or tighter tolerances absolutely demands indexing accuracy within ±0.03mm, making machine condition assessment critical before purchase.

Q: What materials work best on capstan lathes?

A: Brass and brass alloys represent the ideal capstan lathe material, machining cleanly at high speeds while producing excellent surface finishes. Aluminum runs well at high speeds but requires careful coolant management. Mild steel produces acceptable results at moderate speeds. Stainless steel machines poorly—tool wear accelerates dramatically and production rates drop significantly compared to brass. Plastics (acrylic, nylon, delrin) machine efficiently on capstan lathes, often at speeds higher than metals. Material selection profoundly affects tool life, production rates, and financial viability—always confirm material machinability before committing to production.

Q: What maintenance prevents premature machine wear?

A: Consistent lubrication of indexing mechanisms, ways, and spindle nose represents the single most important maintenance task. Establish weekly lubrication schedules and follow them religiously—deferred maintenance rapidly accelerates wear. Verify hydraulic/pneumatic pressure supplies remain at specification; pressure drops indicate system problems developing. Monitor spindle vibration and indexing consistency monthly using simple test methods; deterioration warns of bearing wear or alignment drift developing. Replace air filters in pneumatic systems monthly (more frequently in dusty environments). These preventive measures, costing modest time and resources, extend machine operational life by many years compared to reactive maintenance addressing problems only after failures occur.

Q: How long does setup take for a new component?

A: Typical setup for a new component type requires 1–2 hours for straightforward designs (simple fasteners, basic fittings). More complex components with multiple sequential operations might require 2–4 hours. This setup time includes tool selection, mounting in turret positions, pre-setting depth and feed parameters, running trial cycles, and confirming dimensional results. Setup time becomes negligible when amortized across production runs exceeding 1,000 identical parts but becomes prohibitive for small batches under 100 parts—a fundamental reason CNC dominates short-run production while capstan excels at medium-volume identical parts.

Q: What should I inspect when evaluating a used capstan lathe?

A: Prioritize spindle bearing condition (listen for grinding or growling during test runs), turret indexing accuracy (measure successive tool positions with dial indicators), and cross-slide backlash (excessive play indicates worn components). Check for bed surface flatness with straightedges—warping suggests machine has been dropped or shocked. Inspect hydraulic systems for leakage; even minor leaks signal imminent seal failure. Verify all safety features function (emergency stops, protective guards). Run test cycles without tools engaged, observing smooth turret indexing and consistent positioning. Professional inspection ($500–1,000) by qualified machinists often proves worthwhile investment preventing costly mistakes.

Conclusion

Small automatic capstan lathe machines occupy a unique and irreplaceable niche in modern manufacturing. Despite the prevalence of CNC technology, capstan lathes continue delivering unmatched value for specific production scenarios through rapid cycle times, minimal setup requirements, excellent repeatability, and economical acquisition and operating costs.

When small automatic capstan lathes represent the optimal choice: Your manufacturing situation benefits from capstan lathe investment if you regularly produce batches of 500–5,000 identical small components with tolerances under ±0.1mm using materials like brass, aluminum, or mild steel. Job shops and small manufacturing operations particularly benefit from capstan economics—the ability to produce thousands of identical parts weekly without CNC complexity justifies capital investment consistently.

Conversely, CNC technology becomes preferable if your work emphasizes component variety, complex geometry, or tolerance requirements under ±0.02mm. Single-piece custom manufacturing or frequent design modifications waste capstan machines’ inherent strength (repetition) while failing to utilize CNC’s defining capability (flexibility).

Next steps for buyers and workshop owners: Evaluate your current production patterns honestly. Quantify monthly production volumes by component type, measure current cycle times and operator utilization, and calculate labor costs as percentage of total production cost. If labor costs exceed 30% of component cost and production runs exceed 500 identical units, capstan investment likely produces positive ROI within 12–24 months.

For Indian and Southeast Asian manufacturers, investigate locally-produced models from ABL, Pathak, or Kabir before considering imported equipment—local options typically offer superior spare parts availability and service networks. Expect to invest $12,000–25,000 for quality semi-automatic floor-standing machines from reputable manufacturers. Budget an additional 20% for tooling, fixtures, and initial spare parts before beginning production.

Request demonstrations on live machines before purchasing. Run test cuts in materials matching your actual production needs, then measure results against your tolerance requirements. Purchase used equipment only after professional mechanical inspection, as hidden bearing damage or indexing system wear manifests only through testing.

The small automatic capstan lathe, modernized from 1960s designs but refined through decades of production experience, remains a fundamentally sound technology. With proper maintenance and realistic expectations about its capabilities, capstan investment accelerates production, improves consistency, and strengthens workshop profitability for decades of reliable service.