Why Sidney, OH Lathes Are Still in Demand

The small industrial city of Sidney, Ohio became an unlikely epicenter of American machine tool excellence in the early twentieth century, spawning two legendary lathe manufacturers whose machines continue to command respect—and premium prices—from discerning machinists worldwide. The intertwined histories of Sidney Tool Company and Monarch Machine Tool Company represent a golden era of American precision manufacturing, when quality trumped quantity and machines were built to outlast generations.

Sidney Machine Tool Company traces its origins to 1904–1905 when A.C. Getz established Sidney Machine Works in the former Sebastian-May factory. The company initially produced woodworking equipment under the “Famous” brand before transitioning to metal-cutting lathes around 1910. By World War II, Sidney had abandoned woodworking machinery entirely, focusing exclusively on heavy-duty engine lathes renowned for their distinctive herringbone gear headstocks. Production ceased in early 1964 after corporate acquisitions by Buhr Machine Tool Company (1961), followed by Summerfeld Machine Company (1963), which consolidated operations to Pennsylvania.

Monarch Machine Tool Company opened its doors on October 4, 1909, in a newly constructed 9,960-square-foot facility on Oak Street in Sidney. Founded by industrialist I.H. Thedieck, Monarch traced its lineage to the Sebastian-May Company of Cincinnati—the same firm whose factory Sidney Machine Tool occupied. Monarch began with 20 employees producing only 14″ and 16″ swing lathes, eventually growing into one of America’s most respected precision lathe manufacturers.

The enduring value of vintage Sidney and Monarch lathes stems from several factors:

- Exceptional build quality: Heavy cast-iron frames, precision-ground bedways, and over-engineered components create machines that maintain accuracy for decades

- Rigidity under load: Sidney lathes from the 1940s were deliberately built “massive, squat-looking, and especially powerful” to withstand severe industrial use

- Smooth operation: Sidney’s herringbone (double-chevron) gear headstocks run remarkably quietly and transmit power without vibration

- Parts availability: While original manufacturer support ended decades ago, community resources and aftermarket suppliers keep these machines operational

Collectors prize pristine examples of both brands, particularly rare herringbone-geared Sidney models. Workshop users value them for their ability to handle heavy cuts, exceptional accuracy, and the satisfying mechanical precision that modern imported lathes rarely match.

Sidney & Monarch Lathe Models Overview

Sidney Lathe Series

Sidney lathes evolved through several distinct design phases, ultimately producing some of the finest American engine lathes ever manufactured.

Model Designations and Specifications

From the early 1940s onward, Sidney organized their lathe offerings into model designations expressed in nominal swing inches, though actual swing exceeded the model number by approximately 2.5 inches:

| Model | Actual Swing | Standard Center Distance | Headstock Type |

|---|---|---|---|

| 14″ | 16.5″ | 30″ | 8, 12, 16, or 32 speed |

| 16″ | 18.5″ | 30″ | 8, 12, 16, or 32 speed |

| 18″ | 20.5″ | 48″ | 12 or 16 speed |

| 20″ | 22.5″ | 48″ | 12 or 16 speed |

| 25″ | 27.5″ | 48″ | 16 speed (herringbone) |

| 32″ | 34.5″ | 48″ | 16 speed (herringbone) |

| 36″ | 38.5″ | 48″ | 12 speed |

Longer beds were available in 24-inch increments across all models.

Distinguishing Sidney Features

Sidney lathes incorporated several advanced features that distinguished them from competitors:

- Herringbone gear headstocks: Sidney’s trademark innovation employed double-chevron gears running in constant mesh, with speed changes accomplished via dog clutches engaging internal and external gears on splined shafts. This design produced exceptionally smooth, quiet operation—critical for fine surface finishes.

- Semi-steel cast-iron beds: Massive constructions featuring four longitudinal walls braced every 12 or 24 inches with cross girths

- Optional tool-steel way linings: Replaceable strips of tool steel on bedways, identifiable by their bright chrome-like appearance versus the silvery-grey of standard chilled cast iron

- Pressure-pumped headstock lubrication: Including cast-iron manifolds directing oil to each gear set, with sight glasses for flow verification

Production records indicate Sidney manufactured approximately 5,000 lathes between 1930 and 1962—an average of fewer than 160 machines annually, making well-preserved examples genuinely rare.

Monarch Lathe Line from Sidney, Ohio

Monarch established itself as a benchmark for American lathe quality, evolving from simple belt-driven designs to sophisticated precision toolroom machines.

Key Monarch Models

| Model Era | Notable Models | Key Features |

|---|---|---|

| 1909–1920s | Models A, B, D, E | Cone-drive headstocks, quick-change gearboxes |

| 1924–1940s | Models AA, CY, N | Helical-geared headstocks (first in USA, 1923) |

| 1939–present | 10EE | Legendary precision toolroom lathe |

| 1950s–1970s | Series 60, 62 | Production lathes with Dyna-Shift hydraulic headstocks |

| 1950s–1970s | Series 80 | Heavy-duty engine lathes |

The Monarch 10EE: A Legend

Introduced in 1939, the Monarch 10EE Precision Toolroom Lathe became arguably the finest small lathe ever mass-produced in America. Despite its “10” designation, it actually swings 12.5 inches over the bed with 20 inches between centers.

Key 10EE specifications include:

- Swing over bed: 12.5″

- Swing over cross-slide: 7.25″

- Distance between centers: 20″

- Spindle speeds: Infinitely variable, typically 8–4,000 RPM (later models 25–2,500 RPM)

- Threading capability: 3–184 TPI across 60 changes

- Spindle horsepower: 5–7.5 HP depending on configuration

- Weight: Approximately 3,250–3,450 lbs

The 10EE’s belt-driven spindle, isolated drive system, and precision-ground ways produced work of extraordinary accuracy. Replacement cost for a remanufactured 10EE approaches $80,000, explaining why vintage examples command $7,000–$15,000 or more.

Series 62 Dyna-Shift Production Lathes

Monarch’s Series 62 lathes featured hydraulic Preselector Dyna-Shift headstocks allowing operators to preselect four speeds and step through them at the touch of a lever—a significant productivity advantage for production environments. Models included the 1610, 2013, and 2516 designations indicating approximate swing and center distances.

Sidney-Made Monarch vs. Later Production

Monarch relocated from Sidney to Cortland, New York in 1985, and has since changed ownership multiple times. Sidney-era Monarchs (pre-1985) generally command premium prices due to:

- Heavier castings and more generous material specifications

- Made-in-USA pride of ownership

- Better parts availability through collector networks

- More predictable quality standards

Deep Dive: Sidney 1307 Engine Lathe

The Sidney 1307 represents one of the final Sidney designs, developed in the late 1950s and subsequently sold under the South Bend name after Sidney ceased production.

Core Specifications

The 1307 employed an innovative drive system distinguishing it from conventional gear-head lathes:

The 1307’s DC drive provided infinitely variable spindle speed across an extraordinarily wide range—a significant advantage for both threading and general machining operations.

Common Issues to Inspect

When evaluating a Sidney 1307 or similar vintage lathe, focus inspection on these known trouble areas:

Worn half-nuts: The half-nuts engage the leadscrew for threading operations. Signs of wear include:

- Thread dial lines not aligning properly when engaging

- Excessive carriage movement when half-nuts are engaged (push/pull test)

- Visible thread damage or deformation

Repair options range from bronze re-lining to complete replacement. Original parts may cost hundreds of dollars when available; many machinists opt for machinist-made replacements or brazed rebuilds.

Spindle bearing noise: Listen carefully during startup and at various speeds for:

- Rumbling or grinding sounds indicating bearing wear

- Excessive vibration detectable by touch

- Spindle runout exceeding 0.0005″ measured with a dial indicator

Leadscrew backlash: Test by engaging power feed, stopping, then reversing direction. Excessive play between the leadscrew and half-nuts creates positioning errors during threading and may indicate:

- Worn half-nut threads

- Bent or worn leadscrew

- Damaged leadscrew bearings

Gearbox leaks: The 1307’s Louis Allis drive system and associated gearboxes require proper lubrication. Inspect for:

- Oil seepage around seals and gaskets

- Low oil levels in sight glasses

- Evidence of overheating (burned oil smell, discoloration)

Pros & Cons of the 1307 Model

Advantages for Restoration

- Wide speed range: DC drive provides flexibility unavailable in conventional gear-head designs

- Quality construction: Sidney’s manufacturing standards ensure solid restoration foundation

- Documentation availability: South Bend sold this design, improving manual and parts information access

- VFD compatibility: Many owners successfully convert to modern VFD drives, eliminating troublesome DC generator systems

Why Machinists Value It

- Smooth, vibration-free operation when properly maintained

- Capable of fine finishes across broad material range

- American-made quality with accessible repair parts

- Substantial enough for serious work, compact enough for smaller shops

Limitations Compared to Modern Lathes

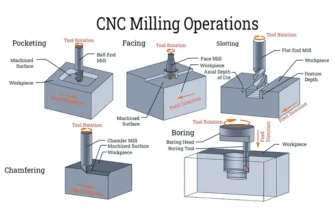

- No CNC capability without extensive modification

- DC drive components may require specialized repair expertise

- Weight and footprint substantial for home shop applications

- Threading requires manual engagement/disengagement versus modern auto-reversing systems

- No digital readout unless retrofitted

Buying Guide — How to Choose a Used Sidney/Monarch Lathe

Inspection Checklist

A thorough pre-purchase inspection can prevent expensive surprises. Approach this systematically:

Electrical System

| Check Point | What to Look For | Red Flags |

|---|---|---|

| Motor condition | Smooth operation, no overheating | Grinding noise, burning smell |

| Wiring | Intact insulation, proper grounding | Exposed wires, non-standard repairs |

| Controls | All switches/buttons functional | Intermittent operation, stuck contacts |

| Voltage requirements | Confirm 220V/440V 3-phase compatibility | Mismatched voltage, single-phase on 3-phase motor |

For 3-phase machines, plan for a phase converter (rotary recommended) or VFD installation, adding $500–$2,000 to acquisition costs.

Ways Wear Test

The bed ways are critical to accuracy and expensive to repair. Use this proven method:

- Move carriage to extreme headstock end

- Mount dial indicator (0.0001″ resolution) on tailstock

- Place indicator point on carriage ways

- Slide tailstock from end to end, recording readings

- Typical wear pattern: greatest depression 12–18″ from headstock where most turning occurs

Accept wear of 0.003–0.006″ for general work; 0.001–0.002″ for precision applications. Wear exceeding 0.010″ may require professional regrinding ($3,000–$10,000+ depending on size).

Carriage Movement

- Check longitudinal and cross-slide movement for smoothness

- Test gib adjustments—properly adjusted slides should move freely without excessive play

- Verify handwheel dials advance smoothly without sticking

- Listen for gear noise when power feeds engage

Threading Gearbox Checks

- Shift through all gear combinations

- Listen for grinding, clicking, or unusual noise

- Check oil level and condition

- Verify threading dial functions correctly

- Engage half-nuts and test for backlash

Pricing Insights

Used Sidney and Monarch lathe prices vary dramatically based on condition, configuration, and market conditions:

| Condition | Sidney 14″–20″ | Monarch 10EE | Monarch Series 62 |

|---|---|---|---|

| Poor (needs major work) | $500–$2,000 | $2,000–$5,000 | $1,000–$3,000 |

| Fair (functional, cosmetic issues) | $2,000–$5,000 | $5,000–$8,000 | $3,000–$5,000 |

| Good (ready to use) | $5,000–$10,000 | $8,000–$12,000 | $5,000–$7,000 |

| Excellent (restored/rebuilt) | $10,000–$20,000+ | $12,000–$25,000+ | $7,000–$12,000 |

Heavy-duty Sidney models (25″ and larger with herringbone headstocks) may command significant premiums due to rarity.

Factors Affecting Value

- Tooling included: Chucks, centers, steady rests, and accessories significantly increase value

- Documentation: Original manuals add 5–15% to asking price

- Completeness: Missing components (especially gears, handles, covers) substantially reduce value

- Provenance: Tool room machines typically show less wear than production shop survivors

- Location: Shipping costs for multi-ton lathes can exceed $1,000

Auctions vs. Private Sellers

Industrial auctions (Bidspotter, machinery auctions) often yield bargains when buyers can inspect beforehand. However, “as-is, where-is” terms shift all risk to buyers, and competition can drive prices beyond private-sale levels.

Private sellers typically offer inspection opportunities and may negotiate on price, accept trades, or provide delivery assistance. Facebook groups, Craigslist, and machinery dealer networks remain productive sourcing channels.

Best Places to Find Sidney Lathes for Sale

Online Marketplaces

- eBay: Active listings for both machines and parts; buyer protection available

- Machineseeker.com: International industrial machinery marketplace

- MachineTools.com: Established dealer network with engine lathe inventory

- Craigslist/Facebook Marketplace: Local sellers often prefer avoiding shipping logistics

Industrial Machinery Auctions

- Harris Machine Tools (Houston): Regular multi-location auctions featuring lathes

- Asset Exchange Corporation: Dealer network with used machinery inventory

- Bidspotter/Proxibid: Online bidding platforms aggregating industrial auctions

Vintage Machine Forums and Communities

- Practical Machinist (practicalmachinist.com): Active classifieds and extensive technical knowledge base

- VintageMachinery.org: Dedicated to vintage machinery history and restoration; classified ads available

- OWWM.org: Old Woodworking Machine forums, covering both wood and metal machinery

- Hobby Machinist: Active community with buy/sell sections

Local Machine Shops Upgrading to CNC

Many precision shops maintain older manual lathes for prototype work or repairs. When shops upgrade to CNC, quality manual machines often become available at reasonable prices. Building relationships with local machinists provides access to equipment before public listing.

Parts & Manuals — Where to Find Authenticated Resources

Manuals for Sidney & Monarch Lathes

Original Paper Manuals

Original manufacturer documentation remains the gold standard for technical accuracy. Sources include:

- Estate sales and shop liquidations

- Collector networks (Practical Machinist classifieds)

- eBay (verify seller reputation; original manuals command $50–$150+)

PDF Archives

- VintageMachinery.org Publication Reprints: Extensive free archive of downloadable manuals, catalogs, and technical documents for both Sidney and Monarch

- Lathes.co.uk Manual Store: Tony Griffiths’ definitive machine tool archive offers reproduction manuals for sale; the site itself provides extensive free technical information

- Archive.org: Monarch operating manuals and other public domain documentation available for download

Third-Party Reproductions

Several vendors specialize in reproduced manuals:

- Ozark Tool Manuals: South Bend/Sidney 1307 operator’s and parts manual available ($49.50); high-quality reproductions from original documentation

- Norman Machine Tool: Monarch 10EE manuals and documentation

Spare Parts Sources

Gears, Belts, Bearings

Standard components can often be sourced from industrial suppliers:

- McMaster-Carr: Bearings, V-belts, timing belts, gaskets

- Grainger/MSC Industrial: Replacement motors, electrical components

- Boston Gear/Martin Sprocket: Change gears when standard pitches match

For non-standard gears, specialized machine tool parts dealers or custom machining may be required.

Electrical Components

DC drive systems (Louis Allis Select-a-Spede, etc.) present particular challenges:

- Machinery Support (MCSpt.com): Parts for over 1,000 machine tool manufacturers including South Bend, specializing in obsolete components

- eBay: Surprisingly productive source for vintage electrical components

- VFD conversion: Many owners bypass troublesome DC systems entirely with modern variable frequency drives

Aftermarket vs. Custom-Machined Parts

When original parts prove unavailable, consider:

- Aftermarket replacements: Some common wear items (half-nuts, gibs, bushings) available from specialty suppliers

- Custom machining: Local machine shops can often reproduce parts from drawings or samples

- 3D printing: For non-critical components (handles, covers, guards)

Avoiding Counterfeit Manuals or Incorrect Parts

Manual Verification

- Confirm manual matches your specific model and serial number range

- Cross-reference part numbers against known documentation

- Beware generic “fits all” claims for model-specific machines

- Verify page count and content list against authentic examples

Parts Verification

- Measure critical dimensions before ordering

- Photograph and document original parts

- Request specifications from seller, not just fitment claims

- When possible, purchase from established dealers with return policies

Trusted Documentation Sources

- VintageMachinery.org (free, extensive, community-verified)

- Lathes.co.uk (Tony Griffiths’ comprehensive archive)

- Practical Machinist forums (decades of archived technical discussions)

Restoration Tips for Sidney and Monarch Engine Lathes

Basic Restoration Steps

Disassembly

Document everything before disturbing original configuration:

- Photograph all assemblies from multiple angles

- Label wires, hoses, and cables before disconnecting

- Bag and tag fasteners by assembly

- Note wear patterns—they indicate usage history and potential problems

Remove components systematically: toolpost, compound, cross-slide, carriage (apron), tailstock, headstock covers, electrical enclosures. Keep assemblies together to prevent parts mixing.

Cleaning & Rust Removal

Electrolysis rust removal has proven exceptionally effective for vintage machinery:

Setup requirements:

- Plastic container large enough for parts

- Sodium carbonate (washing soda) solution: approximately 1 tablespoon per gallon

- DC power source: battery charger (6–12V) for small parts, larger supply for big components

- Sacrificial steel anode (connected to positive terminal)

- Part to be cleaned connected to negative terminal

The process chemically converts rust (ferric oxide) to magnetite, which wipes away easily, while preserving machined surfaces without aggressive abrasion. Processing time ranges from hours to days depending on rust severity.

For painted surfaces, electrolysis also softens paint, often allowing removal in sheets—particularly useful for cast iron with intricate details.

Way Lubrication

Sidney and Monarch lathes require appropriate way oil:

- Use ISO 68 or ISO 220 way oil depending on manufacturer specification

- Clean all oil passages before refilling

- Verify oil flow to all lubrication points

- Establish regular lubrication schedule per manual recommendations

Advanced Repairs

Scraping Ways

For lathes with significant bedway wear, hand scraping can restore geometry without expensive regrinding:

The process involves:

- Using a precision straight edge to identify high spots (bluing compound reveals contact points)

- Selectively removing material from high spots using a scraper

- Creating a characteristic crosshatch pattern providing oil retention

- Working iteratively toward flatness, parallelism, and perpendicularity

Scraping is time-intensive (40–100+ hours for a lathe bed is common) but produces exceptional results when properly executed. Machinists report that comprehensive renovation including way grinding may cost thousands of dollars at professional shops, making DIY scraping attractive for restorations where time exceeds available budget.

Gearbox Overhaul

Systematic gearbox service includes:

- Complete disassembly and inspection

- Measurement and documentation of all wear surfaces

- Bearing replacement (Timken taper roller bearings common on quality machines)

- Gear inspection for tooth damage, wear, or pitting

- Seal and gasket replacement

- Proper reassembly with correct bearing preload

- Fresh lubricant to manufacturer specification

Adding filtration to gearboxes (particularly those with soft-steel gears generating wear particles) can extend service life significantly.

Rewiring Old Motors

Vintage lathe motors may require:

- Insulation testing (megohmmeter) to verify winding integrity

- Bearing replacement if noisy or rough

- Capacitor replacement for single-phase motors

- Terminal cleaning and reconnection

- Ground fault protection installation per modern codes

For 3-phase machines, VFD installation often provides benefits beyond simple phase conversion:

- Infinitely variable speed control

- Soft starting (reduces inrush current)

- Dynamic braking capability

- Energy efficiency improvement

Tools & Materials You’ll Need

Measuring Tools

| Tool | Purpose | Recommended Accuracy |

|---|---|---|

| Dial indicator | Runout, alignment checking | 0.0001″ |

| Dial test indicator | Surface contact measurement | 0.0005″ |

| Magnetic base | Indicator mounting | N/A |

| Precision straight edge | Way flatness checking | Certified accuracy |

| Feeler gauges | Gap measurement | 0.001″ minimum blade |

| Micrometers | Part measurement | 0.0001″ |

Rust Converters and Removal

- Electrolysis setup (detailed above)

- Evaporust or similar chelating rust remover for light surface rust

- Wire brushes (brass preferred to avoid scratching)

- Scotch-Brite pads for light cleanup

- Naval jelly for localized treatment

Paint & Finishing Supplies

- Rust-preventing primer (epoxy-based recommended)

- Machine tool enamel or automotive lacquer

- Masking materials for protecting machined surfaces

- Mineral spirits for cleaning before painting

Recommended & Trusted Sellers

Reputable Vintage Machinery Dealers

Established U.S. Dealers Specializing in Old Lathes

What Guarantees to Expect

Reputable dealers typically offer:

- Inspection opportunity before purchase

- Accurate condition descriptions

- Working demonstration when possible

- Return period for misrepresented equipment (typically 30 days)

- Assistance with rigging and shipping arrangements

Expect to pay 15–30% premium over private-party prices for dealer guarantees and support services.

Top Online Communities with Verified Sellers

Forums

- Practical Machinist (practicalmachinist.com): The largest online machinist community; classified sections with reputation systems; extensive technical archives; particular strength in Monarch and vintage American iron discussions

- Hobby Machinist (hobby-machinist.com): Active community for home shop machinists; buy/sell sections; Sidney lathe discussions available

- VHGMC (vhgmc.co.uk): Vintage and Horizontal & General Machine Club; UK-based but international membership

Facebook Groups

- “Monarch Lathe Owners” and similar model-specific groups

- Regional machinery swap groups

- Vintage machinery restoration communities

Collectors’ Networks

- VintageMachinery.org: While primarily focused on history and documentation, the classifieds section connects serious collectors

- My Old Machine (myoldmachine.com): Forums covering vintage machinery including lathes; 58,000+ total posts from dedicated community

- Smokstak: Antique engine community with overlapping interest in vintage machine tools

Conclusion

Sidney and Monarch lathes from their Ohio heyday represent a pinnacle of American machine tool manufacturing—built to standards that prioritized performance and longevity over production cost. These machines reward patient restoration with decades of reliable service, producing work quality that modern budget imports struggle to match.

Why Sidney and Monarch Lathes Remain a Smart Investment

- Appreciation potential: Quality vintage American machinery has consistently increased in value as remaining examples become scarcer

- Operational excellence: Properly maintained machines produce work indistinguishable from new equipment costing 5–10× more

- Repairability: Unlike sealed modern machines, every component is accessible, measurable, and replaceable

- Community support: Active online communities provide knowledge, parts leads, and troubleshooting assistance unavailable for discontinued imported machines

Quick Tips for Safe Buying and Long-Term Maintenance

Before Purchase:

- Inspect in person whenever possible—photos cannot reveal worn ways or spindle damage

- Test all speeds and feeds; listen for concerning noises

- Verify electrical requirements match your shop capabilities

- Account for rigging/shipping costs (often $500–$2,000 for heavy lathes)

- Request all available documentation and tooling

For Long-Term Maintenance:

- Establish and follow lubrication schedules religiously

- Keep ways clean and protected when not in use

- Address wear promptly—small problems become expensive repairs when ignored

- Maintain documentation of all repairs and modifications

- Connect with online communities for technical support and parts sourcing

Whether you seek a Sidney herringbone-geared heavyweight for serious production work, a Monarch 10EE for precision toolroom operations, or a Sidney 1307 combining both capabilities in a moderately sized package, these Ohio-built machines offer exceptional value for machinists willing to invest in proper inspection, restoration, and maintenance. In an era of disposable manufacturing equipment, owning a piece of American machine tool heritage provides both practical capability and enduring satisfaction.