Key Highlights

- Metal lathe tools are fundamental for shaping and cutting metal with high precision on a lathe machine.

- The effectiveness of turning tools depends on their material, with carbide and HSS being the most common choices.

- A tool holder securely connects the cutting tool to the tool post, and a quick-change tool post significantly boosts efficiency.

- Different lathe tools, like turning, facing, and parting tools, perform specific operations to achieve the desired shape.

- The geometry and condition of the cutting edge directly impact the surface finish and accuracy of the workpiece.

- Proper maintenance, including regular cleaning and sharpening, is crucial for extending tool life and ensuring optimal performance.

Introduction

If you’ve ever wondered how to achieve perfectly shaped metal parts, the answer lies in the right equipment. The world of metalworking relies heavily on the precision and power of the lathe machine. But a metal lathe is only as good as the tools you use with it. This straightforward guide will walk you through the essential lathe tools you need for any high-precision task, stripping away the jargon and getting right to what matters for your projects.

Understanding Metal Lathe Tooling for Precision

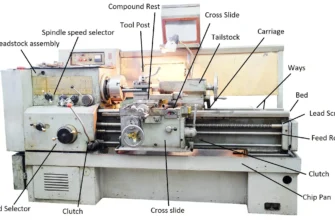

At the heart of any manufacturing process involving a metal lathe is its tooling. These specialized instruments are what perform the actual cutting action, shaping a rotating workpiece into a precise, symmetrical component. Achieving high precision is impossible without understanding how each cutting tool works.

The right turning tools, for example, are designed with a specific cutting edge to remove material efficiently while meeting strict specifications. From simple shapes to complex contours, the interaction between the tool and the metal is key to a successful outcome. We’ll explore the different types of tools that allow you to achieve this level of accuracy.

What Makes a Lathe Tool Essential for Metalworking?

A lathe tool is the essential tool that makes a metal lathe more than just a spinning machine. It’s the point of contact that carves, shapes, and refines a piece of metal into a functional part. Without the correct cutting tool, you simply can’t perform the operations needed to create anything from a simple pin to a complex engine component.

For beginners, a few tools are fundamental. A general-purpose turning tool for shaping the outside diameter, a facing tool for creating flat ends, and a parting tool for cutting the piece off the stock are must-haves. These form the basis of most lathe operations and are the perfect starting point for anyone new to metalworking.

Your choice of tool also depends heavily on the workpiece material and the specific type of lathe you’re using. Harder metals require tougher tools, while certain operations may demand a tool with a unique shape or angle. This adaptability is what makes a well-rounded set of lathe tools so valuable.

Key Components of Metal Lathe Tools

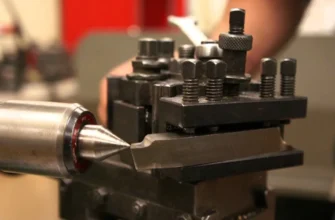

A lathe cutting tool is more than just a single piece. It’s an assembly of key components working together. The two primary parts are the tool bit, which contains the cutting edge, and the tool holder, which secures the bit to the lathe’s tool post. Understanding their distinct roles is a crucial step in mastering lathe work.

The tool bit is the part that does the actual cutting. It can be made from a solid piece of steel or be a holder for a smaller, replaceable carbide insert. The geometry of its cutting edge is precisely ground to perform a specific task. The tool holder, on the other hand, is the bridge between the tool bit and the machine, providing the rigidity needed for clean, accurate cuts.

Here are the main components you’ll encounter:

- Tool Bit: The cutter, shaped for a specific operation.

- Cutting Edge: The sharpened part of the tool bit that removes material.

- Tool Holder: The fixture that clamps the tool bit and mounts to the tool post.

- Boring Bar: A specialized tool and holder combination, often found in a set, used for internal turning.

How Metal Lathe Tools Impact Precision Machining

The quality of your metal lathe tools directly translates to the quality of your finished parts. A sharp, well-maintained cutting edge is the foundation for achieving precise cuts and a smooth surface finish. A dull or chipped tool will tear the metal rather than shear it, resulting in poor accuracy and a rough texture.

Furthermore, factors like the tool’s geometry, the feed direction, and the depth of cut all play a role in the final outcome. A tool designed for finishing will have a different shape than one for roughing. Using the right tool for the job ensures you can control these variables for optimal performance.

Ultimately, maximizing tool life is about more than just saving money; it’s about maintaining consistency. A tool that holds its edge longer will produce more identical parts before it needs sharpening or replacement. This reliability is the cornerstone of precision machining.

Types of Lathe Cutting Tools for Metal

The world of lathe cutting tools is diverse, with different types designed for specific jobs. Each cutting tool has a unique shape and purpose, from removing large amounts of material to creating fine details. Machinists use a wide assortment of these tools to skillfully sculpt metal.

Understanding the main categories is the first step to selecting the right tool for your project. Common types include turning tools for shaping diameters, facing tools for creating flat surfaces, and boring bars for enlarging holes. In the following sections, we’ll look at these and other essential tools in more detail.

Turning Tools for Accurate Shaping

When you need to reduce the diameter of a rotating workpiece, turning tools are your go-to solution. These are among the most common and versatile tools in any machinist’s collection. They are designed to remove material from the outer surface of a part as it spins in the lathe.

Turning tools are generally split into two categories: rough turning tools and finish turning tools. Roughing tools are built for rapid material removal, allowing you to quickly get the workpiece close to its final size. They are strong and can handle a deeper cut.

For precision, finish turning tools are essential. These tools are designed to take a very light cut, creating a smooth surface finish and bringing the part to its exact final dimension. The cutting direction and tool angle are critical for achieving the best results with both types of turning tools.

Facing and Parting Tools Explained

Beyond shaping diameters, lathes perform other critical functions that require specialized tools. A facing tool, for instance, is used to create a perfectly flat surface on the end of a workpiece. It moves from the center outward, or vice-versa, slicing away material to produce a smooth, even finish.

A parting tool has a very different but equally important job: to cut a finished piece off from the main stock of material. This tool is thin and has a sharp cutting edge designed to make a clean, narrow groove until the part separates. Different operations on various types of lathes may require different styles of these tools.

Here’s a quick breakdown:

- Facing Tool: Creates flat surfaces on the end of a workpiece.

- Parting Tool: Cuts off a finished part from the stock.

- Operations: Facing ensures parts are square, while parting is the final step in production.

Threading and Grooving Tools for Detailed Work

For more detailed work, you’ll need tools designed for creating specific features. A threading tool is used to cut the helical grooves that form screw threads on a part. Achieving top-notch threading requires a tool with a precise profile that matches the desired thread shape, whether it’s an external or internal thread.

Similarly, a grooving tool is used to cut narrow channels or grooves into a workpiece. These are often used for creating seats for O-rings, clips, or for decorative purposes. Like thread milling cutters, these tools must be sharp and rigid to produce clean, accurate features without chattering.

The precision required for this detailed work underscores the importance of maintenance. A dull threading or grooving tool will produce poor-quality features. Regular sharpening and careful handling are essential to keep these tools in top condition for when you need them most.

Lathe Tool Bits vs. Tool Holders: Main Differences

It’s easy to get confused between a tool bit and a tool holder, but they have very distinct jobs. The tool bit is the part of the cutting tool that actually makes contact with and cuts the metal. It’s the business end of the operation.

The tool holder, or lathe tool holder, is the component that securely grips the tool bit and mounts it onto the lathe. Its role is to provide a stable, rigid platform, ensuring the tool bit doesn’t move or vibrate during a cut. Understanding this difference is key to setting up your lathe correctly.

Function and Design of Lathe Tool Bits

The primary function of a tool bit is to remove material. Each tool bit is ground to a specific shape with a carefully prepared cutting edge designed for a particular task. Whether you’re turning, facing, or threading, there is a right tool with the correct geometry for the job.

This is where the main difference from a holder becomes clear: the tool bit is the consumable and task-specific part of the cutting tool assembly. It can be made from various materials, each offering different properties. Choosing the right material is just as important as choosing the right shape.

Here’s a look at common tool bit materials: | Material | Best For | |————————–|—————————————————————–| | High-Speed Steel (HSS) | General purpose work, softer materials, easy to sharpen. | | Carbide | Hard materials, high-speed cutting, excellent wear resistance. | | Cobalt | Tough cutting conditions and high temperatures. | | Diamond | Ultra-precision machining and achieving a superior finish. |

Overview of Lathe Tool Holders and Their Importance

A tool holder is the unsung hero of the machining process. Its job is to hold the tool bit with absolute rigidity and align it perfectly with the workpiece. A flimsy or poorly designed tool holder can lead to chatter, a bad surface finish, and even broken tools. It connects the cutting tool to the lathe’s tool post.

Modern lathes often use systems that make changing tools faster and easier. A quick change tool post, for example, uses a set of interchangeable tool holders that slide into a dovetail mount. This allows you to swap between turning, facing, and other tools in seconds without losing your position.

Here are some common types of tool holding systems:

- Standard 4-Way Tool Post: A basic block that holds up to four tools.

- Quick Change Tool Post: Allows for rapid and precise tool swaps.

- Turret Tool Posts: Common on CNC lathes, these hold many tools and rotate them into position automatically.

Choosing Between Tool Bits and Tool Holders for Metalwork

When setting up for a job, your choice of tool bit and tool holder are separate but equally important decisions. The tool bit selection is all about the material you’re cutting and the operation you’re performing. Are you roughing stainless steel or finishing aluminum? The answer determines if you need a carbide or HSS tool bit.

The tool holder choice, however, is about efficiency and the overall machining process. For a one-off part, a simple tool holder might be fine. But for production work or jobs requiring multiple tools, a quick-change tool holder system is invaluable. It drastically reduces setup time between operations.

Ultimately, you can’t achieve high precision without both. A premium tool bit will perform poorly in a weak tool holder, and a great tool holder can’t make up for a dull tool bit. They are two halves of the same coin, and both must be chosen carefully to get the best results from your lathe.

Best Materials for Metal Lathe Cutting Tools

The material your cutting tool is made from determines how fast you can cut, what materials you can machine, and how long the tool will last. The two most common choices are High-Speed Steel (HSS) and carbide. However, for specialized applications involving very hard materials, advanced options exist.

Materials like cubic boron nitride and coatings such as titanium nitride push the boundaries of performance, allowing for machining at extreme speeds and temperatures. Choosing the right material is a balancing act between cost, performance, and the specific demands of your project.

Advantages of Carbide Cutting Tools

Carbide cutting tools are a top choice for modern machining, and for good reason. Their biggest advantage is exceptional hardness and heat resistance. This allows them to maintain a sharp cutting edge at much higher speeds and temperatures than HSS, making them ideal for cutting hard materials like stainless steel and cast iron.

This durability translates directly to longer tool life. While a carbide tool might be more expensive upfront, it often lasts much longer and cuts faster, increasing productivity. Many carbide tools come in the form of a replaceable carbide insert, which can be quickly swapped out when an edge becomes dull.

Choosing a carbide cutting tool is the right move when performance and speed are priorities. If you are working with tough alloys or need to run your lathe at high speeds for production, the superior wear resistance of carbide will give you cleaner cuts and more consistency over the long run.

Benefits of High-Speed Steel (HSS) Tools

High-Speed Steel (HSS) has been a reliable cutting tool material for decades. Its main benefit lies in its toughness and versatility. HSS tools are less brittle than carbide, which means they can handle interrupted cuts and are more forgiving of chatter or less-than-rigid setups, making them a great choice for older machines or hobbyists.

One of the biggest advantages of an HSS tool bit is that it can be easily sharpened by hand on a bench grinder. This allows you to create custom tool shapes for specific jobs and get a lot more life out of a single tool. For general-purpose work on softer materials like aluminum, brass, and mild steel, HSS provides an excellent surface finish.

While not capable of the same high-speed performance as carbide, HSS tools are a cost-effective and practical option for many applications. Their ease of use and ability to be re-sharpened make them an indispensable part of any machine shop.

Specialty and Advanced Tooling Materials

When HSS and carbide aren’t enough, machinists turn to advanced tooling materials. These are designed for the most demanding applications, such as machining hardened steels or superalloys at very high speeds. These specialty materials offer performance far beyond conventional tools.

Cubic Boron Nitride (CBN), for example, is second only to diamond in hardness and can withstand extremely high temperatures. This makes it perfect for finish-machining hardened steel parts. Another approach is to add a coating, like Titanium Nitride (TiN), to a carbide tool. This thin, hard layer reduces friction and increases wear resistance.

Here are some advanced materials and their uses:

- Cubic Boron Nitride (CBN): For machining hardened steels and ferrous materials at high temperatures.

- Diamond (PCD): For ultra-precision machining of non-ferrous and composite materials.

- Ceramics: Offer excellent performance at high temperatures but can be brittle.

- Titanium Nitride (TiN) Coating: A common coating that improves hardness and tool life.

Shapes and Geometries of Precision Lathe Tools

The specific shape of a lathe tool, known as its tool geometry, is just as important as its material. The angles of the cutting edge determine everything from how the chip is formed to the final surface finish. Every tool is ground to a specific shape for an intended cutting action.

This geometry includes the rake, clearance, and cutting edge angles. Even the overall shape, such as whether it is a right hand or left hand tool, impacts how it engages with the workpiece. Understanding these shapes is key to selecting the right tool for any given operation.

Most Common Tool Shapes Used in Metal Lathes

While you can grind a tool bit into almost any shape, a few common tool shapes handle the majority of lathe work. These are often sold in a pre-ground tool set and serve as the foundation for any machinist. The most basic distinction is between right hand and left hand tools.

A right hand tool cuts while moving from right to left (from the tailstock toward the chuck), while a left hand tool cuts when traveling from left to right. This is important for turning up to a shoulder or for certain CNC operations. Other common shapes are designed for specific tasks like cutting threads or grooves.

Here are some of the most common shapes you’ll find:

- Right Hand Turning Tool: For general turning towards the headstock.

- Left Hand Turning Tool: For turning away from the headstock.

- Round Nose Tool: A versatile shape for smooth finishes and contouring.

- Pointed (Threading) Tool: Ground to a 60-degree point for cutting threads.

How Tool Geometry Affects Finish and Accuracy

The geometry of your cutting tool has a direct and significant impact on both the surface finish and the dimensional accuracy of your part. The angles ground into the tool control how it interacts with the metal, and even small variations can make a big difference.

For example, the nose radius of the tool—the roundness of its tip—is critical for achieving a smooth surface. A larger radius can smooth out the tiny ridges left by the feed direction, but too large a radius can increase cutting forces and cause chatter. The rake angle affects how the chip flows away from the workpiece, influencing heat and finish.

Proper tool geometry also helps manage cutting forces. By directing these forces correctly, you can prevent the workpiece or tool from deflecting, which is essential for maintaining accuracy over the entire length of a cut. This is why selecting a tool with the right geometry for your material and depth of cut is so important.

Selecting the Correct Shape for Your Project

How do you choose the right tool shape for your project? Start by identifying the primary operation you need to perform. If you are reducing the diameter of a shaft, a turning tool is what you need. If you are making a flat face, you need a facing tool.

Next, consider the features of the part. If you need to cut a groove, you need a tool with a specific shape and width to match. If you are turning a part with multiple diameters and shoulders, the cutting direction matters. You might need both a right hand and a left hand tool to access all the surfaces without interference.

Finally, think about the desired finish. For roughing, a tool with a strong cutting edge that can handle a deep cut is best. For finishing, you’ll want a tool with a geometry designed to produce a fine surface, often with a specific nose radius. Matching the tool shape to the task is a fundamental skill in machining.

Maintaining and Sharpening Metal Lathe Cutting Tools

A cutting tool is only effective when it’s sharp and well-cared-for. Proper tool maintenance is not just about extending tool life; it’s about ensuring safety, accuracy, and optimal performance every time you use your lathe. This includes cleaning, storage, and, most importantly, sharpening.

Regular sharpening restores a tool’s cutting edge to its original geometry, allowing it to cut cleanly and efficiently. A dull tool requires more force, generates more heat, and produces a poor surface finish. The following tips will help you keep your tools in top condition.

Expert Tips for Cleaning, Care, and Storage

Good tool maintenance begins the moment you finish a job. Cleaning your tools after each use removes metal chips and cutting fluid, which can cause rust and corrosion over time. A light coat of oil before storage provides an extra layer of protection.

Proper care also means handling your tools carefully. Carbide, in particular, is brittle and can easily chip if dropped or knocked against another hard object. Protecting the cutting edge is the most important part of tool care, as this is where all the work happens.

Organized storage is the final piece of the puzzle. Keeping tools in a dedicated drawer or rack prevents them from banging into each other and makes it easy to find the one you need.

- Clean tools thoroughly after every use.

- Apply a light oil to prevent rust, especially on HSS tools.

- Store tools so their cutting edges are protected.

- Inspect tools for chips or wear before each use.

- Never throw tools into a drawer together.

Sharpening Techniques for Longevity and Performance

Sharpening is a critical skill for any machinist, especially when working with HSS cutting tools. The goal of sharpening is to restore the original angles of the tool edge, as this geometry is what ensures a proper cutting action. This is typically done on a bench grinder with a fine-grit wheel.

When sharpening, it’s important to maintain the correct clearance and rake angles. The clearance angle prevents the tool from rubbing against the workpiece behind the cut, while the rake angle controls chip formation. Getting these angles right is key to optimal performance.

Take your time and use a light touch to avoid overheating the tool edge, which can soften the steel and ruin its hardness. Dip the tool in water frequently to keep it cool. A properly sharpened tool will not only cut better but will also last longer before it needs to be sharpened again.

Essential Lathe Accessories for Metalworking Success

To get the most out of your lathe, you’ll need more than just cutting tools. A range of lathe accessories can enhance your machine’s capability, improve your workflow, and make complex jobs much easier. These can range from a better tool holder system to specialized attachments.

Items like a quick change tool post, a good set of center drills, and a versatile boring bar set are not just conveniences; they are essential for efficient and accurate work. For beginners especially, having the right accessories can significantly shorten the learning curve.

Must-Have Accessories for Beginners

If you’re just starting with metalworking, a few key lathe accessories will make your life much easier and your projects more successful. These items help with setting up work, changing tools, and performing basic operations more efficiently. Investing in them early on is a smart move.

Perhaps the single most useful upgrade for a beginner is a quick change tool post. It replaces the standard tool post and uses a set of holders that let you swap tools in seconds with repeatable accuracy. This saves a huge amount of time compared to shimming and aligning tools manually.

Here are some must-have accessories to get started:

- A quick change tool post and a basic set of tool holders.

- A set of center drills for starting accurate holes.

- A drill chuck for the tailstock to hold the center drills and drill bits.

- A quality starter tool set with pre-ground HSS or carbide tools.

- A dial indicator for precise measurements and alignment.

Specialized Attachments for Advanced Machining

Once you’ve mastered the basics, you can expand your lathe’s capabilities with specialized attachments for advanced machining. These tools allow you to perform operations that would be difficult or impossible with a standard setup. For example, a knurling tool creates a textured grip pattern on handles and knobs.

A high-quality boring bar set is another essential for advanced work. While a basic bar is fine for simple holes, a set with multiple diameters and lengths allows you to tackle deep bores and internal features with minimal tool deflection, which is critical for accuracy.

Other attachments might include a taper turning attachment for creating precise cones, or specialized rests to support long, slender workpieces. These tools, combined with a good selection of rough turning tools and finish turning tools, open up a new world of complex projects.

Quick Change Tool Posts and Turrets

Efficiency is key in any machine shop, and nothing boosts productivity on a manual lathe like a quick change tool post (QCTP). This device replaces the traditional four-sided post and uses a dovetail mechanism to clamp individual tool holders in place. A simple lever lock allows you to swap out a cutting tool in seconds.

Each tool is mounted in its own tool holder, and its height is set once. After that, you can switch from a turning tool to a boring bar to a parting tool without having to re-align anything. This dramatically reduces downtime between operations.

On CNC lathes, this concept is taken a step further with turret tool posts. A turret can hold a dozen or more tools and automatically rotates the correct one into the cutting position as directed by the program. Both QCTPs and turrets are fundamental to modern, high-productivity machining.

CNC Lathe Tooling: Advancing Metal Machining

The arrival of Computer Numerical Control (CNC) has revolutionized metal machining, and CNC lathe tooling is at the forefront of this change. These systems use automated processes to achieve a level of precision, speed, and repeatability that is difficult to match manually.

CNC tooling is designed for high performance and increased productivity. With automated tool changes and optimized cutting paths, CNC lathes can produce complex parts with incredible efficiency. This technology has become the standard in industries from aerospace to automotive.

Benefits of Using CNC Tooling in Metal Lathes

The primary advantage of using CNC tooling is the huge leap in precision and productivity. Because the machine’s movements are controlled by a computer program, every part produced is virtually identical. This automation removes the potential for human error, leading to higher quality and less waste.

This level of automation allows for advanced machining operations that would be extremely challenging on a manual lathe. CNC tooling is designed to work seamlessly with these automated systems, enabling complex contouring, threading, and other operations to be performed quickly and flawlessly.

Here are the key benefits of CNC tooling:

- Precision: Unmatched accuracy and repeatability from part to part.

- Productivity: Faster cycle times and automated tool changes dramatically increase output.

- Complexity: Enables the creation of highly complex geometries with ease.

- Reduced Labor: A single operator can often oversee multiple machines.

Real-World Applications and Increased Productivity

The impact of increased productivity from CNC lathes is visible across countless industries. In the aerospace sector, CNC machines produce complex turbine blades and structural components from tough superalloys with a level of accuracy that is critical for safety and performance. These are clear real-world applications of the technology.

In the automotive industry, a CNC lathe can churn out thousands of identical engine components, from pistons to driveshafts, every day. The speed and reliability of modern turning tools in a CNC environment are essential for meeting the demands of mass production.

Even in prototyping and custom work, CNC lathes excel. They allow designers to quickly turn a digital model into a physical part, test it, and make modifications rapidly. This ability to iterate quickly accelerates development and innovation in nearly every field of engineering.

Integrating CNC Accessories with Manual Setups

You don’t need a full CNC machine to benefit from some CNC accessories. Many modern tooling components designed for CNC use can be adapted to upgrade manual setups, leading to enhanced operations and better results on a traditional metal lathe.

For example, high-quality tool holders and indexable carbide inserts, which are standard in CNC tooling, can be used in a quick change tool post on a manual lathe. This gives you the performance and convenience of carbide without the cost of a full CNC machine.

Similarly, digital readout (DRO) systems are a popular CNC accessory that can be retrofitted to a manual lathe. A DRO provides a precise digital display of the tool’s position, eliminating the need to count handwheel revolutions and dramatically improving accuracy. These integrations can breathe new life into an older machine.

Selecting and Buying Quality Metal Lathe Tools

Choosing and purchasing quality tools is a critical investment in your workshop. A good lathe tool or tool set will not only last longer but will also produce better results and be safer to use. With the rise of e-commerce, it’s easier than ever to find what you need online.

However, buying online requires some care. You need to know what to look for to ensure you’re getting a quality product and not a cheap imitation. Many reputable suppliers offer a wide selection, often with perks like free shipping.

What to Look for When Purchasing Online

When shopping for lathe tools online, the first thing to look for is a detailed product description. A reputable seller will provide clear information about the tool’s material (e.g., M42 Cobalt HSS, C6 carbide), dimensions, and intended use. Vague descriptions are a red flag.

Customer reviews are another valuable resource. See what other machinists are saying about the quality and performance of the tool bit or holder. Look for patterns in the feedback. Do the carbide tools hold an edge well? Are the holders rigid? This firsthand information is often more telling than the product description itself.

Finally, consider the seller’s reputation and policies. Buying from established industrial suppliers or specialty tool retailers is generally safer than buying from a generic marketplace.

- Check for detailed material specifications.

- Read customer reviews and look for photos of the tools in use.

- Look for quality tools from trusted brands or suppliers.

- Compare prices, but don’t let price be the only factor.

- Check for reasonable return policies and customer support.

Popular Brands in the U.S. Market

In the U.S. market, several popular brands have built a reputation for producing reliable and high-quality lathe tools. While brand names can be a good indicator of quality, it’s more important to understand what makes these brands popular. They consistently deliver on performance, material quality, and precision.

These leading brands typically offer a wide range of products, including both HSS tools for general use and advanced carbide tools for high-performance applications. They invest in quality control to ensure that every tool bit and lathe accessory meets tight tolerances, which translates to better accuracy in your work.

When you invest in a tool from a well-regarded brand, you are often paying for that consistency. You can be confident that the carbide grade is what it claims to be and that the geometry of the tool is ground correctly. This reliability is why many professional machinists stick with a few trusted names for their most critical tools.

Trusted Suppliers and Shopping Tips

Finding trusted suppliers is the key to successfully buying any lathe tool online. Look for dedicated machining and industrial supply companies rather than general-purpose online retailers. These suppliers have expertise in the products they sell and can often provide better technical support.

A great shopping tip is to start small. If you’re trying a new supplier, buy a single tool bit or a small item first to gauge its quality and the company’s service. Once you’ve confirmed they are reliable, you can place larger orders with more confidence.

Don’t forget to factor in shipping costs. Many online suppliers offer free shipping on orders over a certain amount, which can be a significant saving, especially on heavy items. By combining these shopping tips and sticking to trusted suppliers, you can build a collection of high-quality tools that will serve you well for years.

Conclusion

In conclusion, investing in the right lathe tools for metalworking is crucial for achieving precision and efficiency in your projects. Understanding the various types of tools, their materials, and how to maintain them can significantly elevate your metalworking experience. Whether you are a beginner or an experienced machinist, selecting the appropriate tooling and accessories tailored to your needs will ensure superior results. Remember, the right tools not only enhance your craftsmanship but also contribute to the longevity of your equipment. If you found this guide helpful, don’t hesitate to share it on social media to help others in their metalworking journey!

Frequently Asked Questions

How do I choose between carbide and HSS lathe cutting tools?

Choose HSS tools for general-purpose work, softer materials, and if you plan to sharpen your own tools. Opt for carbide tools when machining hard materials, running at high speeds, or when long tool life is a priority. Carbide’s superior heat resistance allows for optimal performance in demanding applications.

Are there specific lathe accessories that make metalworking easier for beginners?

Yes, absolutely. A quick change tool post is the most impactful accessory, as it saves significant time. Other helpful items for beginners include a quality starter tool set, a tailstock drill chuck, and a set of center drills. These accessories simplify common tasks and improve accuracy.

Where can I buy high-quality metal lathe tools online?

You can buy high-quality metal lathe tools online from trusted suppliers specializing in industrial and machining equipment. Look for retailers with detailed product descriptions, positive customer reviews, and clear return policies. Many of these suppliers also offer free shipping, which can help reduce the overall cost of your tool bit purchase.