Unlock Your Metalworking Potential

A benchtop metal lathe is more than just a tool; it’s the heart of a precision workshop. For hobbyists, prototypers, and small-business owners, it transforms a garage or shop from a place of simple repairs into a hub of creation. This single machine unlocks the ability to turn raw metal stock into custom parts, threaded fasteners, intricate models, and functional tools with remarkable accuracy. The growing global metalworking equipment market, valued at USD 100.5 billion in 2025 and projected to grow, underscores the central role these machines play in both industrial and personal fabrication (Fortune Business Insights, 2025). This guide is designed to navigate the complex world of benchtop lathes, helping you select the perfect machine to bring your ideas to life.

The Versatility of a Benchtop Metal Lathe in Your Workshop

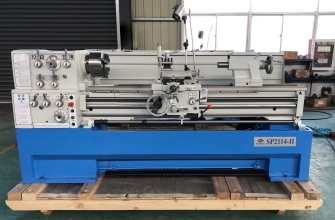

A metal lathe’s versatility allows for multiple precision operations on a single workpiece.

A metal lathe’s versatility allows for multiple precision operations on a single workpiece.

The core function of a metal lathe is to rotate a workpiece against a cutting tool, a process that enables a vast range of machining operations. In a home shop or garage, this versatility is invaluable. You can perform facing operations to create perfectly flat surfaces, turning to reduce the diameter of a part, drilling to create precise holes along the central axis, and threading to make custom bolts or nuts. Beyond these basics, a lathe can be used for knurling, polishing, and even some light milling with the right accessories. This capability makes it indispensable for everything from automotive restoration and firearm customization to creating scientific instruments and bespoke hardware.

Why Choosing the Right Lathe Matters for Precision and Longevity

Not all lathes are created equal. The difference between a budget-friendly model and a high-quality machine often comes down to rigidity, component quality, and attention to detail during manufacturing. A well-built metal lathe with minimal vibration and precisely aligned parts is the foundation for achieving tight tolerances. This precision is critical for parts that need to fit together perfectly. Furthermore, a robustly constructed machine will withstand the rigors of heavy use for years, making it a long-term investment rather than a short-term tool. Choosing the right lathe from the outset saves you from the frustration of inaccurate work and the future cost of a necessary upgrade.

What This Guide Will Cover: From Basics to Top Picks

This guide will demystify the process of selecting a benchtop metal lathe. We’ll start by helping you define your specific needs, from project scope to budget. Next, we will break down the essential technical specifications—like swing, spindle bore, and motor type—translating them into practical terms that matter for your machining work. Finally, we will present our curated list of top benchtop lathes, categorized to help you find the best option for your workshop, whether you’re a complete beginner or a seasoned machinist demanding the highest precision.

Decoding Your Needs: Essential Questions Before You Buy

Before diving into specifications and models, a self-assessment is crucial. The best lathe is not necessarily the most expensive or feature-rich machine; it’s the one that aligns perfectly with your projects, space, budget, and skill level. Answering these fundamental questions will create a clear framework for your decision.

What Are You Making? Project Scope and Materials

First, consider the primary purpose of your lathe. Will you be making small, intricate parts for models or clocks, requiring exceptional precision but not massive capacity? Or are you planning to work on larger components for automotive or machinery repair, where size and power are paramount? The diameter and length of your typical workpieces will directly influence the required swing and distance between centers. Similarly, think about the materials you’ll be machining. Softer metals like aluminum and brass are less demanding, while steel, stainless steel, and titanium require a more rigid machine with a powerful motor to achieve a good finish without chatter.

Space Constraints: Benchtop Machine vs. Workshop Footprint

A key advantage of a “benchtop” metal lathe is its relatively compact size, making it suitable for a garage or small shop. However, “benchtop” is a broad term. Smaller mini-lathes might be only a few feet long and weigh under 100 pounds, while larger, more capable benchtop models can exceed five feet in length and weigh several hundred pounds. Measure your available bench space carefully, accounting not only for the machine’s footprint but also for the necessary clearance around it for operation, maintenance, and storing tooling. Remember to consider the logistics of delivery and placement; a 500-pound lathe is not something you can easily move on your own.

Your Budget Reality: Machine, Tooling, and Accessories

Your budget is a primary constraint, but it’s essential to look beyond the sticker price of the lathe itself. The initial purchase is just the beginning. A new lathe often comes with only the most basic accessories, such as a 3-jaw chuck. To make it truly functional, you will need to invest in a significant amount of tooling. This includes cutting tools, measuring instruments (calipers and micrometers), a 4-jaw chuck, a drill chuck for the tailstock, live centers, and potentially a quick-change tool post. A realistic budget should allocate at least 30-50% of the lathe’s cost for this essential tooling and future accessories.

Your Skill Level: Beginner, Hobbyist, or Advanced User

Your experience level should guide your choice. For a beginner, a user-friendly machine with good customer support and a comprehensive manual can make the learning curve much smoother. Features like variable speed control simplify operation. Advanced users, on the other hand, might prioritize raw precision and rigidity over convenience, and may be comfortable with tuning and adjusting a machine to wring out its maximum performance. They might also consider the used market, where older, high-quality American-made lathes can be found, though they often require significant refurbishment.

Understanding Key Benchtop Lathe Specifications: Beyond the Numbers

Technical specifications can be intimidating, but understanding them is key to matching a lathe’s capabilities to your needs. Here’s a breakdown of the most critical specs and what they mean for your machining work.

Swing Over Bed and Distance Between Centers: Max Workpiece Size

These two numbers define the maximum physical dimensions of a workpiece you can machine.

- Swing Over Bed: This is the maximum diameter of a workpiece that can be rotated without hitting the bed (the main horizontal beam of the lathe). A lathe with a 9-inch swing can turn a workpiece up to 9 inches in diameter.

- Distance Between Centers: This measures the maximum length of a workpiece that can be mounted between the headstock and tailstock centers. A 20-inch distance between centers can accommodate a part up to 20 inches long.

Motor Power and Type: Brushed vs. Brushless Advantage

The motor is the heart of the lathe. Its power, typically rated in horsepower (HP) or watts, determines how aggressively you can remove material, especially in tougher metals like steel.

- Brushed DC Motors: Common on smaller, budget-friendly lathes. They are cost-effective but can lack torque at low speeds, and the brushes are a wear item that will eventually need replacement.

- Brushless DC Motors: Increasingly common on higher-quality benchtop lathes. They offer superior torque across the entire speed range (especially at low RPMs), run quieter, are more efficient, and require less maintenance.

Spindle Bore and Through-Hole Size: Capacity for Bar Stock

The spindle bore is the diameter of the hole that runs through the headstock spindle. This specification is critical if you plan to work with long pieces of bar stock. A larger spindle bore allows you to pass a longer rod through the headstock, securing it in the chuck and machining the end without having to cut it to length first. This is a massive convenience for production-style work or when making multiple small parts from one long bar.

Spindle Speed and Variable Speed Control: Precision for Different Materials

The ability to control the spindle’s rotational speed (RPM) is essential for achieving a good surface finish and ensuring tool longevity. Different materials and operations require different speeds; large diameter work and hard metals need slower speeds, while small diameter work and softer metals can be cut at higher speeds.

- Manual Gear/Belt Changes: Found on some older or basic models, requiring you to stop the machine and manually move belts on pulleys or shift gears to change speed.

- Variable Speed Control: A dial allows you to change the speed dynamically while the motor is running. This is a highly desirable feature for convenience and precision, allowing you to fine-tune the cutting speed on the fly.

Guideways: V-Way vs. Flat Bed and Their Impact on Accuracy

The guideways on the lathe bed are the precision-ground surfaces on which the carriage and tailstock slide. Their accuracy is paramount to the overall precision of the machine.

- V-Ways: These triangular-profile ways provide a self-aligning surface that resists cutting forces from multiple directions, contributing to greater accuracy and repeatability. Most quality lathes use at least one V-way for guiding the carriage.

- Flat Ways: Simpler to manufacture, these are often paired with V-ways. A combination of V-ways and flat ways is a common and effective design.

Precision Matters: Spindle Runout and Tailstock Alignment

- Spindle Runout: This measures the amount of wobble or deviation from a perfect circle as the spindle rotates. Lower runout (measured in ten-thousandths of an inch) is crucial for high-precision work.

- Tailstock Alignment: The tailstock must be perfectly aligned with the headstock spindle’s axis. Misalignment will result in tapered, rather than cylindrical, parts when turning between centers. Good lathes offer a way to adjust this alignment.

Gearbox Design: Oil-Bath vs. Dry Gear Trains

Many lathes use a set of change gears to control the feed rate for power feeding and thread cutting. Higher-end models feature an integrated gearbox.

- Oil-Bath Gearbox: The gears are enclosed and run in a constant bath of oil. This provides continuous lubrication, reduces wear, ensures smooth operation, and extends the life of the parts.

- Dry Gears: Found on many mini-lathes, these gears (often plastic or metal) are not enclosed and require manual lubrication. They are louder and more prone to wear.

The Headstock and Tailstock: Core Components Explained

The headstock and tailstock are the two main pillars of the lathe.

- Headstock: This is the fixed assembly on the left side of the lathe. It houses the main spindle, the motor, and the gearing mechanism. All the power and rotation originate here.

- Tailstock: This is the movable assembly on the right side that slides along the bed. Its primary functions are to support the end of a long workpiece with a center and to hold tooling like drill chucks for drilling holes in the workpiece’s center.

Safety Features: Emergency Stop Button and More

Modern lathes should include essential safety features. An emergency stop button (a large, red, mushroom-shaped button) should be prominently located to quickly shut off all power. Chuck guards, often with an interlock switch that prevents the lathe from starting if the guard is open, are another critical safety feature.

Top Benchtop Metal Lathes: Our Curated Picks for Every Workshop

Choosing a specific model depends on balancing the factors discussed above. Here are our top picks, categorized for different user needs and workshops.

Best Overall Value: Versatile Workhorses for Hobbyists and Small Shops

For this category, we recommend models like the Precision Matthews PM-1022V/PM-1030V or the Grizzly G0602. These 10-inch swing lathes offer a fantastic balance of size, features, and quality. They typically feature a powerful brushless motor, variable speed control, an adequate spindle bore for most hobbyist work, and a solid cast-iron construction that provides the necessary rigidity for machining steel. They represent a significant step up from mini-lathes and provide a platform that a user can grow with for many years without feeling limited. Customer support and parts availability for these brands are generally reliable.

Best for Precision & Quality: High-End Benchtop Options

When ultimate precision is the goal, the Precision Matthews PM-1228VF or similar high-end import models stand out. These machines are built to tighter tolerances, often featuring hardened and ground beds, higher-quality bearings, and meticulous quality control from the factory. They are heavier and more rigid, which directly translates to finer surface finishes and the ability to hold tighter tolerances. While they come at a premium price, for those doing professional-level work or demanding the best possible accuracy from a benchtop machine, the investment is justified.

Best Budget-Friendly / Beginner-Friendly: Getting Started Without Breaking the Bank

The 7×14 or 8×16 class of mini-lathes, sold under various brand names like VEVOR, is the undisputed entry point for many beginners. These machines are affordable and capable of excellent work on smaller parts in aluminum, brass, and even mild steel. They offer features like variable speed and are small enough for any garage bench. However, be prepared for a trade-off. The fit and finish can be inconsistent, and they often require some initial “fettling”—cleaning, deburring, and adjusting—to achieve their best performance. They are a fantastic way to learn the fundamentals of machining without a large financial commitment.

Best Compact Lathe: For Limited Workshop Space

For those with severely limited space, such as model makers or jewelers, a micro-lathe from a brand like Sherline or Taig is an excellent choice. These are American-made, high-precision machines designed for very small-scale work. While their workpiece capacity is small, their build quality and the precision they can achieve are exceptional. They also have an extensive ecosystem of dedicated accessories. They are not designed for heavy material removal in steel but excel at intricate work on small parts where accuracy is paramount.

Considering Specialized Lathes: Brief Mention of Engine and Turret Lathes

While our focus is on benchtop models, it’s worth knowing about their larger industrial cousins. Engine lathes are the larger, floor-standing workhorses found in professional machine shops, offering greater power, rigidity, and capacity. Turret lathes are designed for production work, featuring a multi-tool turret instead of a traditional tailstock, allowing for rapid, repetitive machining operations.

Other Noteworthy Benchtop Lathes

The market is full of strong contenders. The Grizzly G0768 is a popular choice for its solid build and gunsmithing-friendly features. The Weiss WBL1835 offers robust German design influences. For those seeking European quality, lathes from Palmgren, Emco, or Prazi are highly regarded, though often at a higher price point. Finally, no discussion is complete without mentioning classic used machines like the South Bend 9A, an American-made icon prized for its quality, though it requires a commitment to restoration and sourcing parts.

Essential Tooling and Accessories: The True Cost of Ownership

A lathe by itself is incomplete. The tooling and accessories are what unlock its full potential. Budgeting for these items from the start is critical for a positive experience.

Must-Have Workholding: The 3-Jaw Chuck and Beyond

Most lathes come with a 3-jaw self-centering chuck, which is perfect for quickly gripping round or hexagonal stock. However, you will immediately want to add a 4-jaw independent chuck. This allows you to hold square or irregular-shaped parts and, more importantly, to dial in a workpiece with extreme precision. Other essential workholding accessories include a drill chuck for the tailstock and a set of live and dead centers for supporting work between the headstock and tailstock.

Cutting Tools: A Beginner’s Starter Kit

You’ll need a variety of cutting tools to perform different operations. A good starting point is a set of High-Speed Steel (HSS) tool blanks. These can be ground into custom profiles for turning, facing, threading, and parting off. They are affordable and forgiving for beginners. Additionally, an indexable carbide tool set is a great investment. These use replaceable carbide inserts, eliminating the need for sharpening and providing excellent performance in a wide range of materials.

Conclusion

Choosing the right benchtop metal lathe is a significant decision that will shape the capabilities of your workshop for years to come. The journey begins not with a catalog, but with an honest assessment of your projects, space, budget, and skill. By translating specifications like swing, spindle bore, and motor type into tangible benefits for your work, you can move beyond the numbers and select a machine that truly fits your needs.

For beginners, a budget-friendly mini-lathe offers an accessible entry into the world of machining. For the dedicated hobbyist, a versatile 10-inch lathe provides a robust platform for growth. And for the user demanding the utmost accuracy, a high-precision model delivers professional-grade results. Remember to factor in the crucial investment in tooling and accessories, as they are what truly bring your lathe to life. By making an informed choice, you are not just buying a piece of equipment; you are investing in the potential to create, repair, and innovate, turning your garage or shop into a center of precision manufacturing.