The Allure of Bowl Turning and the Right Lathe

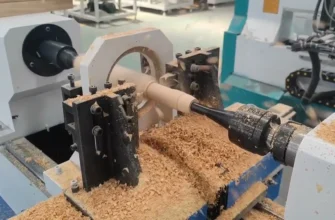

The transformation of a raw block of wood into a polished, elegant bowl is a magical process, central to the art of wood turning. This craft hinges on the synergy between the woodturner’s skill and the capability of their machine. Choosing the right wood lathe isn’t just a technical decision; it’s the first crucial step in defining the scope of your creative potential.

With the global woodworking machinery market projected to reach USD 5.5 billion by 2033, and the specialized wood lathe market expected to grow to USD 0.3 billion in that same period, manufacturers are releasing more advanced and specialized equipment than ever before. However, selecting the perfect wood lathe machine can feel daunting. This guide is designed to demystify the process, helping you find the ideal partner for your bowl turning journey.

Why Bowl Turning Demands Specific Lathe Considerations

Unlike spindle turning for projects like table legs or pens, bowl turning presents unique challenges. A bowl blank is often heavy, unbalanced, and short, placing immense stress on the lathe’s headstock, spindle, and motor. The process requires significant torque to shape the wood, stability to absorb vibration, and a specific physical configuration to allow the woodturner access to the inside and outside of the piece.

A lathe that excels at making pens – like a basic model from Harbor Freight – may struggle profoundly with even a moderately sized bowl. Bowl turning often involves faceplate turning or using a chuck, where the wood is held from one end only, requiring a robust spindle and bearings to handle the overhung load.

Understanding Lathe Types Through a Bowl Turner’s Lens

For a woodturner focused on bowls, machine sizes correspond directly to project possibilities.

Mini Lathes: Ideal for Small Bowls & Craft Projects

Mini lathes are compact, benchtop machines typically offering a swing (maximum bowl diameter) of 8 to 12 inches. They are an excellent entry point into woodturning, perfect for crafting small decorative bowls, dishes, and items like bottle stoppers.

- Limitations: Their smaller motor (usually 1/2 to 3/4 HP) is adequate for small tasks but will strain under the weight of larger or green wood blanks.

- Recommendation: While affordable, a serious bowl turner may outgrow a mini lathe quickly. However, they make excellent secondary machines for dedicated small work.

Midi Lathes: The Versatile “Everything In Between” Choice

The midi lathe is often the sweet spot for the dedicated hobbyist bowl turner. With a swing typically ranging from 12 to 16 inches and more powerful motors (1 to 1.5 HP), these machines offer a significant step up in capability without the massive footprint of a full-size lathe.

Modern midi lathes have evolved significantly:

- Jet 1221VS: A market staple known for its rock-solid stability and smooth electronic variable speed. It offers a 12-inch swing and is a favorite for those who want reliability.

- Rikon 70-1420VSR: This machine pushes the “midi” definition with a 14-inch swing and a sliding headstock, allowing you to turn outboard for larger capacities – a rare feature in this class.

- Harvey T40: Known as a “Turbo” lathe, it features an industrial servo motor system that delivers incredible torque at low speeds, essential for coring out a bowl without stalling.

- Record Power Herald: A unique benchtop marvel with a rotating headstock that allows for turning bowls up to 21 inches off the side of the bench.

- Nova Neptune: A “smart” lathe using Direct Drive (DVR) technology. It lacks belts and pulleys, using a computer to maintain speed even under heavy cuts, and features a digital display with intelligent load sensing.

Full-Size & Professional Lathes: Conquering Large Bowls & Hollow Forms

Full-size lathes are the titans of the woodturning world. Built from heavy casting iron, they are designed for maximum stability. With a swing of 16 inches up to 24 inches and motors of 2 HP or higher, they can handle massive logs and large-diameter platters with ease.

- Powermatic 4224: Often considered the gold standard for American workshops, this lathe features a sliding headstock and immense mass to dampen vibration.

- Oneway 2436: A Canadian masterpiece featuring a unique tubular steel bed design for torsional rigidity. It is a favorite among professionals for turning massive hollow forms.

- General 260: While no longer in production, this Canadian-made lathe is a legendary find on the used market. If you spot a “General 260” or the rarer “26020” (20-inch swing) in good condition, it is worth snapping up.

The Bowl Turner’s Essential Lathe Specifications Checklist

Beyond general size categories, the technical details determine a lathe’s true performance.

Swing: How Much Diameter Do Your Bowls Need?

Swing is the single most important metric for a bowl turner. It is defined as twice the distance from the center of the spindle to the lathe bed. A lathe with a 12-inch swing can accommodate a 12-inch blank. Always consider your future ambitions; choosing a lathe with a slightly larger swing than you currently need provides valuable room to grow.

Motor Power & Torque: The Heartbeat for Big Bowls

For bowl turning, torque is just as important as horsepower. Roughing out an unbalanced blank requires immense torque at low speeds.

- DC Motor vs. AC Inverter: High-end lathes often use a 3-phase motor with an AC inverter or a DC motor to provide consistent torque across the RPM range.

- Power Requirements: A 1/2 HP motor allows for small dry bowls. For bowls over 10 inches or wet wood, a minimum of 1 HP is recommended. For professional work, 2 HP or more ensures the machine won’t bog down.

Variable Speed Control: Precision for Every Bowl Stage

Variable Speed Control is a non-negotiable feature for serious bowl turning.

- Electronic Variable Speed (EVS): This allows you to adjust RPM via a variable speed knob rather than manually moving a belt.

- Safety: You must start a large, imbalanced blank at a very low speed (often below 200 RPM) to true it up. EVS provides the control needed to do this safely.

- Pulley Belt System: Even with EVS, most lathes have 2 or 3 belt ranges. Using the “low” belt range maximizes torque for roughing, while the “high” range is for finishing.

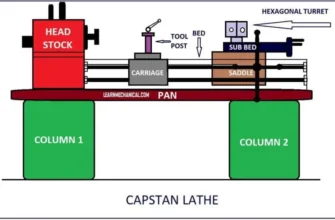

Lathe Bed, Headstock & Spindle

- Construction: Look for a solid cast iron bed. The mass is essential for dampening vibration.

- Headstock Threads & Taper: The headstock threads (commonly 1″ x 8 TPI or 1-1/4″ x 8 TPI) must match your chucks. The Morse taper (usually MT2) is the standard socket for accessories like the drive center.

- Bearings: The drive shaft should be supported by heavy-duty bearings to withstand the side-load pressures of bowl turning.

- Indexing Pin: A useful feature for decorative work, allowing you to lock the spindle at specific intervals.

- Quill Lock: Located on the tailstock, this locks the quill in place to prevent movement during drilling or support.

Tailstock, Banjo, & Tool Rest

The tail stock is invaluable for initial mounting. It supports the blank while you turn a tenon. The banjo is the sliding base that holds the tool rest. It must lock down securely without slipping. A smooth, hardened steel tool rest allows your bowl gouge to glide effortlessly during cuts.

Essential Accessories & Tools for Dedicated Bowl Turning

Chucks, Centers, & Mounting

- Four-Jaw Scroll Chuck: The workhorse of bowl turning. It grips the tenon of your bowl, allowing you to remove the tailstock and hollow the inside.

- Faceplate: A metal disc screwed directly into the bowl blank for the most secure hold possible during the initial roughing phase.

- Drive Centers:

- Live Center: A ball-bearing center that goes in the tailstock to support the spinning wood without burning it.

The Core Bowl Turning Tool Kit

While there is a vast array of woodturning tools available, a bowl turner relies on a specific set:

- Bowl Gouge: The primary tool with a deep flute, used for both roughing and finishing cuts. Look for high-quality M2 HSS steel (High-Speed Steel) which holds an edge longer than older carbon steel tools.

- Scrapers: Heavy-duty scrapers are used to refine the internal curves and remove tool marks.

- Spindle Gouge: Generally used for detail work on the outside of the bowl or the foot.

- Skew Chisel: Caution: Rarely used inside a bowl due to the risk of catches, but excellent for planing the exterior of a cylinder or cutting precise beads.

- Handles: Many turners prefer long beechwood handles for vibration absorption and leverage.

Tip: A pre-assembled kit like the Axminster Woodturning Tool Set can be a cost-effective way to get all these essentials at once.

Practical Considerations for the Aspiring Bowl Turner

Workspace & Lathe Height

- Lathe Height: The spindle centerline should be at elbow height.

- Counter Space: Ensure you have nearby counter space for your tools and chucks.

- Link Belt: On older or belt-driven lathes, upgrading to a segmented Link belt can significantly reduce vibration.

Dust Management & Safety

Health & safety are paramount.

- Dust Extraction System: A dedicated dust collector is vital, as bowl turning produces large volumes of fine dust and heavy wood shavings.

- PPE: Always wear a full-face shield. A security check of your setup (speed, tool rest position, blank tightness) should be performed before hitting the start button.

- Emergency Stop: Ideally, your lathe should have a large, accessible off-switch or knee-bar for emergencies.

Budgeting for Your Bowl Lathe Investment

Price Points: What to Expect

- Mini Lathes: $300 – $800.

- Midi Lathes: $800 – $2,500. Models like the Nova Neptune and Harvey T40 sit at the premium end of this range but offer professional features.

- Full-Size Lathes: $3,000 – $10,000+.

Note: Pricing strategies often see significant discounts during holiday sales or at woodturning symposiums.

New vs. Used

A used General 260 or Oneway 2424 can be an incredible bargain. When buying used, check the head stock bearings and the condition of the bed ways.

Conclusion

Choosing the best bowl lathe is a personal journey that balances ambition, space, and budget. For the aspiring bowl turner, the decision hinges on three key factors: a generous swing to accommodate your desired bowl size, a powerful motor with excellent Variable Speed Control, and robust, heavy construction to manage vibration.

While a mini lathe is a fine entry point for small crafts, a quality midi lathe like the Rikon 70-1420VSR or Jet 1221VS often represents the wisest long-term investment, offering a perfect blend of capacity and value.

Woodturning skills take time to develop. Join local turning clubs, attend a craft show, or scan a QR code on modern machine manuals to watch video tutorials. Your lathe is the foundation of your workshop. By carefully considering its specifications and investing in essential accessories like a quality chuck and sharp tools, you are setting yourself up for a safe, rewarding, and creative journey. The perfect machine is waiting – the one that will empower you to take the next step and transform raw wood into functional art.