Turning Your Ideas into Reality

The lathe is far more than just a piece of workshop equipment; it is a gateway to creation. Whether you’re a woodturner shaping a raw block into a graceful bowl or a machinist crafting a precise metal component, the lathe is the centerpiece of transformative work. This powerful tool, which spins a workpiece on its axis, allows for a range of operations including cutting, sanding, knurling, and drilling with exceptional symmetry and precision.

The global lathe machine market is valued at USD 26.3 billion in 2024 and is projected to reach USD 38.8 billion by 2033, growing at a CAGR of 4.19%. This market expansion is a testament to the lathe’s foundational role in both hobbyist workshops and industrial manufacturing, driven by increasing demand for precision engineering, automation, and advanced machining capabilities across automotive, aerospace, and general manufacturing sectors.

The Allure of the Lathe: Crafting with Precision and Power

The appeal of the lathe lies in its unique ability to bring rotational symmetry to life. For the woodturner, it’s about revealing the hidden grain and form within a piece of wood, creating functional items and art with equal finesse. For the metalworker, it’s about achieving exacting tolerances, cutting threads, and fabricating parts from raw steel or aluminum stock that are impossible to create by hand.

The combination of a powerful motor, a sturdy frame constructed from materials like cast iron or steel, and precise controls gives the user unparalleled command over the material. This enables everything from manual turning with traditional hand tools to advanced automated operations. The wood turning community – including turning clubs and woodturning organizations – has long recognized the lathe as the essential tool for serious craft practitioners.

What This Guide Offers: Expert Insights for Your 2026 Purchase

Choosing the right lathe can be a daunting task. The market is filled with options ranging from compact mini lathes to heavy-duty industrial machines, with emerging CNC technology expanding capabilities further. This comprehensive guide is designed to cut through the noise by providing in-depth analysis of lathe types, components, and expert recommendations for 2026.

We break down the essential components, explain critical specifications, and provide expert-vetted recommendations for both woodworking and metalworking applications. Whether you’re making your first purchase, upgrading from a beginner mini lathe to a midi lathe, or seeking an industrial metal lathe for a professional machine shop, this guide will provide the clarity needed to invest in equipment that aligns with your skill, space, and ambition.

Understanding Your Needs: The Foundation of a Smart Lathe Purchase

Before diving into specific models and specifications, the most critical step is honest self-assessment. A lathe is a significant investment in both cost and space, and your specific needs will dictate the right choice. Answering a few key questions upfront will narrow the field and prevent costly mistakes.

Wood Lathe vs. Metal Lathe: A Fundamental Distinction

The first and most important decision is the material you intend to work with. While they operate on the similar principle of a rotating workpiece, wood and metal lathes are fundamentally different machines and not interchangeable.

Wood Lathe (Woodturning Lathe): A wood lathe is designed for the lower forces and higher speeds of shaping wood. It features a simple tool rest for manually supporting chisels and gouges, particularly bowl gouges used for faceplate turning and hollow forms. The headstock typically contains a scroll chuck or faceplate for holding workpieces.

Metal Lathe (Benchtop Metal Lathe or Industrial Metal Lathe): A metal lathe is built for precision and power. It has a rigid construction with a leadscrew for automated tool movement, carriage and cross-slide assemblies to hold cutting tools with high precision, and advanced features like a gearbox for cutting threads of various pitches. These machines handle hard materials like steel and are essential for machine shop operations requiring tight tolerances and repeatable accuracy.

Skill Level & Aspiration: Matching the Lathe to the Turner

Are you a beginner exploring a new hobby, or an experienced craftsman looking to expand your capabilities?

A novice woodturner might be best served by a user-friendly mini wood lathe, which is less intimidating and perfect for learning fundamentals on smaller projects like pens and small bowls. An aspiring professional seeking serious woodturning work will need a full-sized lathe with more power, capacity, and features like variable speed control and electronic variable speed (EVS) systems.

Similarly, a hobbyist machinist might start with a benchtop metal lathe, while a commercial machine shop requires an industrial machine capable of handling heavy-duty work. Many professionals and serious enthusiasts eventually add specialized equipment like end mills and phase converters to their workshops as their needs evolve.

Space & Power Constraints: Fitting a Lathe into Your Workshop

Physical limitations are a practical reality. Measure your available workshop space carefully, accounting for not just the lathe’s footprint but also the necessary clearance to work around it safely and handle long workpieces.

A mini lathe can fit on a sturdy bench, while a full-sized lathe requires significant floor space and clearance. Additionally, check your electrical supply. Most smaller lathes run on standard 110V power, but larger, more powerful motors often require a 220V circuit, which may necessitate an electrical upgrade or consultation with an electrician. Some facilities benefit from a phase converter if upgrading to three-phase equipment.

Budget Considerations: Investing Wisely

Lathes range from a few hundred to tens of thousands of dollars. While it’s tempting to buy the cheapest option, it’s often wiser to invest in the best quality you can afford. A well-built machine from a reputable brand offers better performance, greater safety, and holds its value over time.

Consider the total cost of ownership, including essential accessories like chucks (4-jaw chuck options for metalworking, scroll chucks for woodturning), cutting tools, tool rests, and safety gear. For many, a high-quality used machine from established manufacturers like Powermatic, South Bend, or Laguna offers more value than a new, lower-tier model.

Lathe Anatomy 101: Key Components & Their Functions

Understanding the core components of a lathe is essential for evaluating its quality and suitability for your work. Each part plays a critical role in the machine’s overall performance, from delivering power to providing stable support.

The Headstock: Power and Precision at the Core

The headstock is the business end of the lathe. It houses the main spindle, the drive system (belts and pulleys or a gear train), and the motor. The spindle is the rotating shaft that holds the workpiece, typically via a chuck or faceplate.

The quality of the headstock’s precision bearings directly impacts the accuracy of the turning. A key specification is the spindle thread size (e.g., 1″ x 8 TPI or 1¼” x 8 TPI), which determines compatibility with a wide range of essential accessories. The spindle bore and through-bore diameter also affect what tooling and accessories you can use.

The Tailstock: Support for Longer Workpieces

Positioned opposite the headstock on the lathe bed, the tailstock provides crucial support for longer pieces of stock, preventing them from whipping or flexing under tool pressure. It slides along the bed and can be locked in place. The tailstock contains a quill that can be advanced with a handwheel, often fitted with a live center or dead center to engage the end of the workpiece.

For spindle work and distance between centers (a critical specification), the tailstock’s range of travel and precision are paramount. An Acme thread on the quill ensures smooth, reliable operation.

The Bed: The Lathe’s Foundation

The bed is the structural backbone of the lathe, connecting the headstock and tailstock. In high-quality lathes, the bed is made from heavy, cast iron or precision ground steel to provide mass and rigidity, which is vital for dampening vibration.

Vibration is the enemy of a clean finish and accurate work. The precision-ground flat or V-shaped “ways” on top of the bed allow the tailstock and tool rest assembly to slide smoothly and accurately. Steel beds, while less common than cast iron, offer excellent longevity and are used in models like the Laguna Revo 18/36.

The Banjo & Tool Rest: Control and Comfort

Specific to a wood lathe, the banjo is a heavy casting that sits on the bed and can be positioned anywhere along its length. It holds the tool rest, which is the adjustable metal bar that the turner rests their chisels on for support and leverage during turning.

A well-designed banjo and tool rest assembly is easy to adjust and locks down securely, providing a stable platform for precise tool control. Multiple tool rest styles – straight rests for general work, curved rests for interior bowl work, and box rests for hollowing – enhance versatility and control.

The Motor & Drive System: Powering Your Projects

The motor provides the power to turn the spindle. Its horsepower (HP) rating is a primary indicator of the lathe’s capability. A more powerful motor can handle larger, heavier, or out-of-balance workpieces without stalling.

The drive system transmits this power to the spindle. Simpler lathes use a step-pulley system with a belt tensioning system where the belt must be manually moved to change speeds. More advanced models feature an electronic variable speed drive or variable speed knob for seamless control. Many modern variable speed systems also include a servo shift or VFD (variable frequency drive) technology to maintain consistent torque at all speeds.

Critical Specifications & Features: What Really Matters in 2026

When comparing lathes, manufacturers’ spec sheets can be overwhelming. Focusing on a few key metrics will help you evaluate a machine’s practical capacity and performance for the type of work you want to do.

Swing Over Bed: Maximizing Your Project Diameter

“Swing” is the maximum diameter of a workpiece that can be rotated on the lathe without hitting the bed. A lathe with a 12-inch swing can turn a bowl or platter up to 12 inches in diameter. Some lathes also list a “swing over tool rest base,” which is a smaller number indicating the maximum diameter with the banjo in place.

For faceplate turning and large wood turning projects, the swing over bed is one of the most critical specifications defining the absolute size limit.

Distance Between Centers (DBC): For Longer Spindle Work

This measurement defines the maximum length of a workpiece that can be mounted between the headstock and tailstock centers. If you plan to turn long spindles for projects like table legs, chair parts, or baseball bats, a larger distance between centers is essential.

Many midi lathes and full-sized machines offer optional bed extensions to increase this capacity, providing valuable future-proofing for expanding projects.

Motor Power (HP) & Type: Performance Under Load

Motor power, measured in horsepower (HP), dictates how much material you can remove in a single pass and how well the lathe handles large or unbalanced workpieces. Mini wood lathes typically have motors from 0.5 to 1 HP, midi lathes from 1 to 1.5 HP, while full-sized woodturning machines can have 2 HP or more.

For benchtop metal lathes and industrial machines, power requirements are higher, often 1-3 HP or more. Look for motors with a continuous duty rating (often TEFC – Totally Enclosed, Fan Cooled) as they are designed for long-term use without overheating.

Variable Speed Range & Control: Precision at Your Fingertips

Electronic variable speed (EVS) is now a highly desirable standard feature, not a luxury. It allows you to change the spindle RPM with the simple turn of a variable speed knob or dial, without stopping the machine to move a belt.

This enables you to find the perfect speed for any operation, from roughing out an unbalanced blank at low RPM to fine sanding at high RPM. A wide speed range (e.g., 200-3,600 RPM for wood lathes or specialized ranges for metal lathes) and a digital readout offer the ultimate in control and safety.

Construction Material & Build Quality: Durability and Vibration Control

The heavier a lathe is, the better it will absorb vibration. Look for machines with extensive use of cast iron in the bed, headstock, and tailstock. Solid construction ensures stability and longevity. Check the fit and finish of components like locking levers and handwheels. Smooth operation and tight tolerances are signs of quality manufacturing that will translate to a better turning experience.

Specialized Features for Metalworking Lathes

For metal lathes, additional features are critical:

- Gearbox or change gears: Necessary for cutting threads of different pitches and working with nylon gears

- Power feed: Allows the carriage to move automatically along the bed for a consistent finish

- Precision cross-slide and compound rest: Essential for making accurate cuts and achieving repeatable tolerances

- Spindle speeds and controls: Forward and reverse gears, lever controls, and stable speed settings for different materials

- Tailstock and tool post quality: MT3 or MT4 Morse tapers, rigid construction for holding end mills and cutting tools securely

The growing CNC machine tools market, which often includes advanced lathes with digital controls and linear guide rails, highlights the industry’s move toward greater automation, precision, and consistency. Industrial metal lathes for machine shops increasingly incorporate CNC technology for improved repeatability and reduced setup times.

Expert-Vetted Lathe Picks for 2026: Top Recommendations

Based on extensive performance analysis, build quality, features, and user feedback from the woodturning and machining communities, here are our top picks for lathes in 2026 across several key categories.

Best Mini & Midi Wood Lathes: Ideal for Beginners & Hobbyists

Best Overall Midi: JET JWL-1221VS

The JET JWL-1221VS often considered the gold standard in its class, represents an excellent balance between affordability and performance. This variable speed lathe features:

- Motor: 1 HP at 115V single-phase

- Swing Over Bed: 12½ inches

- Distance Between Centers: 20½ inches (20mm spindle bore)

- Speed Range: 60-900 RPM, 110-1800 RPM, 220-3600 RPM

- Key Features: Smooth electronic variable speed control, solid cast-iron construction, forward/reverse switch, 24 integrated indexing positions, patent-pending belt tensioning system, Acme thread tailstock

- Ideal For: Both beginners exploring woodturning and advanced turners seeking a reliable midi lathe

The 1221VS is a versatile workhorse suitable for pen turning, small bowls, spindle work, and projects requiring moderate capacity. Its digital readout and tool rest positioning make it user-friendly for learning lathe fundamentals.

Best Budget Mini: WEN 3421

For those on a tight budget or with limited space, the WEN 3421 mini wood lathe offers excellent entry-level value:

- Motor: 0.5 HP (3.2 amps) at 120V single-phase

- Swing Over Bed: 8 inches

- Distance Between Centers: 12-13 inches

- Speed Range: 750-3200 RPM with variable speed control

- Key Features: Soft-start motor, lever clamping system, two interchangeable tool rests, MT1 spindle and tailstock taper, compact footprint (28″ x 9″ x 12.25″)

- Ideal For: Beginners learning pen turning, small bowl projects, and hobbyists with space constraints

The WEN 3421 is an excellent entry-level mini lathe machine for those starting their woodturning journey without a significant financial commitment.

Best Full-Sized Wood Lathes: For Serious Woodturners

Best Value Full-Size: Laguna Revo 18|36

This lathe strikes an excellent balance between professional-grade features and reasonable pricing:

- Motor: 2 HP at 220V single-phase (1 phase input via VFD converts to 3 phase output)

- Swing Over Bed: 18 inches

- Distance Between Centers: 36 inches

- Speed Range: Low 50-1300 RPM, High 135-3500 RPM

- Bed Construction: Steel (not cast iron), allowing smooth headstock travel with reduced vibration

- Key Features: VFD with electronic variable speed, digital RPM readout, ergonomic angled control panel, spring-loaded spindle lock, quick-release handle for speed ranges, 14/36/48 spindle indexing positions

- Optional Features: Bed extensions available for increased capacity

Ideal for serious hobbyists and professionals turning large bowls and vessels. The steel bed provides excellent longevity and requires minimal lubrication compared to traditional cast iron.

The Gold Standard: Powermatic 3520C

For those seeking the best without compromise, the Powermatic 3520C represents the pinnacle of full-sized woodturning lathes:

- Motor: 2 HP at 220V single-phase

- Swing Over Bed: 20 inches

- Distance Between Centers: 35.5 inches (36 inches working distance with centers installed)

- Speed Range: Low 15-1200 RPM, High 40-3200 RPM

- Key Features: Sliding headstock for outboard turning and hollow forms, moveable control box, adjustable riser blocks (6″ of height adjustment), digital spindle speed and indexing readout, anti-rotation tailstock key, Acme thread tailstock quill, electronic variable speed

- Optional Features: 18-inch bed extension for increased spindle capacity (available; optional bed extension in low position provides 38″ maximum outboard capacity)

- Construction: Heavy-duty cast iron throughout (726 lbs, 814 lbs with bed extension), virtually eliminating vibration

The Powermatic 3520C (fourth generation, improved over the Powermatic 3520B) is an industry icon built for the most demanding woodturning tasks. Its immense weight provides an exceptionally smooth turning experience and unwavering stability. This is the machine of choice for professional woodturners and serious enthusiasts tackling ambitious projects.

Best Benchtop & Industrial Metal Lathes: Precision for Metalworking

Best Benchtop: Grizzly G0602

The Grizzly G0602 is a popular choice for home machinists and small machine shops, offering fantastic features for its size and price:

- Motor: 1 HP, 110V, single-phase, 13.6A

- Swing Over Bed: 9½ inches (10″ in some specs)

- Swing Over Cross Slide: 6⅛ inches

- Distance Between Centers: 22 inches

- Spindle Bore: 25mm (1″)

- Spindle Thread: 1¾” x 8 TPI (MT#4 taper)

- Spindle Speeds: 6 speeds: 150, 300, 560, 720, 1200, 2400 RPM

- Threading Capability: 33 inch threads (8-72 TPI), 26 metric threads (0.25-3.5mm)

- Key Features: Gearbox for thread cutting, hardened and ground V-ways, oil-bath gearbox, full-featured carriage and apron assemblies, 5″ 3-jaw chuck and 6½” 4-jaw chuck included

- Ideal For: Hobbyist machinists, small shops, and professionals handling small-to-medium-sized steel, aluminum, and brass projects

This benchtop metal lathe is capable and versatile, suitable for learning metalworking and handling precision work requiring tight tolerances.

Industrial Standard: South Bend Lathes

For those seeking uncompromising precision, durability, and heritage, South Bend Lathes remain a benchmark in professional machine shops:

- Heritage: Founded in 1906, South Bend became the largest exclusive manufacturer of precision lathes globally by 1930

- Construction: Meehanite bed castings, precision-made bearings, German and Japanese components

- Reputation: Renowned for exceptional build quality, precision, and longevity

- Modern Options: South Bend now offers both classic manual models and advanced CNC variations like the SB1009 Super Precision Digital Threading Collet Lathe

- Applications: Professional machine shops, educational institutions (vocational schools), and precision manufacturing facilities

- Long-term Investment: South Bend lathes represent a significant upfront investment but offer multi-decade service life and excellent resale value

- New vs. Used: Well-maintained used South Bend lathes often represent better value than new mid-tier competitors, given their legendary precision and durability

South Bend lathes exemplify the industrial metal lathe category and remain fixtures in professional machine shops worldwide.

Essential Lathe Accessories & Attachments: Expanding Your Capabilities

The lathe itself is only part of the equation. The right accessories are what unlock its full potential, allowing you to securely hold a variety of workpieces and perform different operations safely and efficiently.

Lathe Chucks: The Heart of Workpiece Holding

A scroll chuck is one of the most critical accessories for any woodturner. It features adjustable jaws that can grip the outside or inside of a workpiece, making it essential for turning bowls, platters, and other non-spindle projects.

For metalworking, a 4-jaw chuck provides independent jaw control for irregular-shaped stock, while a 3-jaw chuck offers quick setup for round or previously-turned stock.

Chucks come in various sizes (e.g., 5-inch, 6½-inch, 8-inch) and thread onto the headstock spindle, so ensuring compatibility with your lathe’s spindle thread size is vital.

Faceplates & Drive Centers: Securing Diverse Projects

A faceplate is a simple metal disc that screws onto the spindle, allowing you to attach a large, irregular block of wood with screws. It is the most secure way to mount a large bowl blank for initial roughing and faceplate turning of hollow forms.

A drive center (or spur drive) is used at the headstock for spindle turning, biting into the wood to provide the rotational force, while a live center in the tailstock spins freely to provide support without burning the wood.

Tool Rests & Supports: Optimizing Control and Comfort

Having a variety of tool rests enhances control and safety for woodturning:

- Standard straight rest: Versatile for general-purpose spindle and bowl work

- Curved rests: Better for interior bowl work and accessing deep grain patterns

- Box rests: Provide extra support for hollowing operations and fragile wood

- Steady rest: Can be mounted to the bed to provide additional support in the middle of a long workpiece, preventing vibration and flexing on extended spindle work

Specialized Metalworking Accessories

For machine shop work, accessories include:

- End mills: For cutting precise shapes and profiles

- Taper shank end mills: For direct mounting in MT tapers

- Tool posts: 4-way tool post for holding and positioning cutting tools

- Dies and threading tools: For cutting threads with the gearbox

- Dust collector: Essential for workshop safety and material management

- Magnetic polishing machine: For finishing operations on ferrous metals

Choosing Between New and Used Machines

New Machines Offer:

- Full warranty protection

- Latest features and technology (digital controls, variable speed systems)

- Predictable condition and performance

- Service support from manufacturers

Used Machines (Especially Quality Brands):

- Significantly lower cost

- Often better value when selecting from quality manufacturers like South Bend, Powermatic, or Laguna

- Proven track records with real-world feedback

- Greater capacity and features at the price of new entry-level machines

Research manufacturer reputation and look for models with strong market presence and user community support, whether from turning clubs, Fine Woodworking magazine, or online forums.

Specialized Considerations for Different Niches

Harbor Freight and Budget Alternatives

Harbor Freight offers budget-conscious options like WEN products that can be suitable for beginners. While not competing with premium brands in terms of longevity or performance, these machines can serve as learning platforms before investing in higher-end equipment.

Emerging Brands and Models

Quality lathes extend beyond the traditionally established names. Brands like Nova Neptune, Rikon 70-1420VSR, Record Power Herald, Oneway 2424 and Oneway 2436s, Harvey T40, Penn State TCLPROVS, Penn State TCLC10VS, and Delta 16-42 Steel Bed lathe offer competitive alternatives with strong user bases.

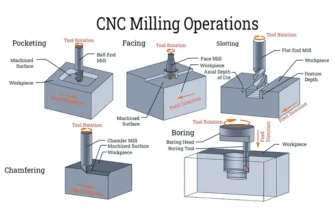

CNC and Automated Systems

The growing CNC machine tools market is transforming the lathe industry. Modern CNC frame lathes with digital controls and linear guide rails offer precision and repeatability for production work. These systems employ standard modern machining practices and serve both traditional machine shops and new-generation manufacturing facilities.

Manual vs. Modern Approaches

While manual turning remains the gold standard for artistic and craft applications, the integration of modern features like servo shift technology and working area optimization reflects the industry’s evolution toward blending traditional craftsmanship with contemporary engineering.

Safety: The Non-Negotiable Priority

No matter the machine, understanding its operation and using proper personal protective equipment is paramount. Recent workplace safety data underscores the inherent risks of working with powerful machinery:

- Keep long hair tied back and avoid loose clothing

- Always wear appropriate safety gear including eye protection

- Never reach across a spinning workpiece

- Maintain a firm stance with good balance

- Understand emergency stops and power-down procedures

- Inspect the lathe before each use for loose components or damage

- Use proper speeds for your workpiece and material

Professional guidance through woodturning clubs, Fine Woodworking resources, and manufacturer documentation is invaluable for developing safe practices.

Investing in Your Craft

Choosing the best lathe in 2026 is a decision that balances ambition with practical constraints of budget and space. By first understanding your own needs – whether for woodworking or metalworking, beginner projects or professional production – you can effectively navigate the market.

Focus on the core components and critical specifications that truly matter: solid construction (cast iron or precision ground steel) for vibration control, a motor with sufficient power for your intended projects, and the capacity (swing over bed and distance between centers) to bring your ideas to life. Features like electronic variable speed are no longer a luxury but a key element for precision and safety.

Your final selection, whether it’s a compact mini lathe for a small workshop or a full-sized machine for heavy-duty turning, should be viewed as a long-term investment in your craft. The right equipment, paired with quality accessories and proper safety practices, will enable you to produce superior work while making the process safer and more enjoyable.

Remember that the lathe industry continues to evolve. Staying informed through industry resources, connecting with turning clubs and user communities, and understanding both traditional manual turning and modern technology will help you make a choice that serves your needs for years to come. Take the time to research, invest wisely, and you will be rewarded with a machine that transforms your creative visions into tangible reality for decades.