If you are seeing chatter marks on your long workpieces or hearing a “screaming” bearing noise from your tailstock, it is time to upgrade your Live Center.

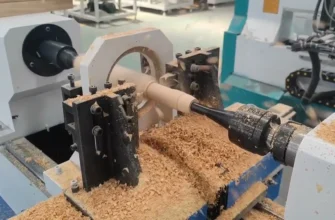

Most CNC and manual lathes come with a cheap, “throwaway” center. Switching to a Heavy Duty Triple-Bearing Live Center is the single cheapest upgrade you can make to improve surface finish and concentricity.

Whether you are a hobbyist using a Mini Lathe (MT2) or running a production CNC (MT4/MT5), this guide reviews the top options for 2025.

Quick Answer: The Top Picks

| Category | Brand / Model | Taper | Runout (TIR) | Verdict |

|---|---|---|---|---|

| Best Budget | Hyuduo Heavy Duty | MT3 | ~0.005″ | ⭐⭐⭐ Perfect for wood/light metal hobbyists. |

| Best Value | Shars Triple Bearing | MT2/3/4 | 0.0002″ | ⭐⭐⭐⭐⭐ The “Prosumer” choice. Excellent for the price. |

| High Precision | Accusize Industrial | MT3/4 | 0.0001″ | ⭐⭐⭐⭐⭐ For CNC precision work. |

Understanding the Tech: Why “Triple Bearing” Matters

You will see the term “Triple Ball Bearing Design” on almost every listing. Here is what it actually means:

- Deep Groove Ball Bearing: Handles the radial load (the weight of the heavy part).

- Thrust Ball Bearing: Handles the axial load (the pressure of the tailstock pushing against the part).

- Needle Roller Bearing: Located in the nose, this eliminates “play” or wobble at the tip.

Why upgrade? Standard “single bearing” centers cannot handle the side-load of heavy cuts. A Triple Bearing design allows for higher RPMs (often 3000+) and heavier roughing cuts without the tip overheating.

Review 1: The Budget King – Hyuduo MT3 Live Center

If you are looking for a replacement center under $30, the Hyuduo MT3 is the current Amazon bestseller.

- Build: High-carbon steel with a carbide-embedded tip (60 degrees).

- Sealing: Features a front dust-proof seal. This is critical if you use flood coolant, as it prevents cutting fluid from washing out the grease inside the bearings.

- Performance: Rated for ~3000 RPM.

- Good For: Wood turning, light aluminum/brass work, and general support.

- Not For: Holding 500lb steel shafts or aerospace tolerances.

⚠️ Warning: The runout on these budget units is typically around 0.002″ – 0.005″. If you are making engine pistons, spend more. If you are making bushings or handles, this is perfect.

Review 2: The Step Up – Shars Heavy Duty CNC Center

Shars Tool is the go-to brand for “Prosumer” machinists in the USA.

- Precision: Guaranteed 0.0002″ Total Indicator Runout (TIR). This is 10x more precise than the budget options.

- Load: The “Heavy Duty” models have a significantly thicker body and larger bearings, allowing for aggressive steel removal.

- Price: ~$60 – $110.

Essential Add-On: Center Drills

You cannot use a live center without a center hole.

- The Problem: Many beginners try to use a standard twist drill. This “walks” and creates an off-center hole.

- The Solution: You must use a 60-Degree Center Drill (Combined Drill & Countersink).

- Recommendation: Buy a HSS Center Drill Set (#1 – #5). The 60-degree angle perfectly matches the tip of your MT3 Live Center, ensuring maximum contact area and rigidity.

Buying Guide: MT2 vs. MT3 vs. MT4

Before you buy, check your lathe’s Tailstock Quill Taper.

- MT2 (Morse Taper 2): Common on mini-lathes (7×10, 7×14) and small wood lathes.

- MT3: The standard for mid-sized bench lathes (10″, 12″ swing) and older Bridgeport mills.

- MT4/MT5: Found on industrial CNC lathes (Haas ST-10, Mazak) and heavy manual engines.

Pro Tip: You can use a smaller taper (like MT2) in a larger tailstock (MT3) using a Sleeve Adapter, but you lose rigidity. Never adapt “up” (MT3 in an MT2 hole).

FAQ: Common Issues

Q: My live center gets hot. Is that normal?

A: Warm is okay; hot means failure. If it burns your hand, either the bearings are shot, or you are applying too much tailstock pressure. Back off the quill handwheel slightly – the center should spin freely with the part.

Q: Can I repair a live center?

A: Industrial ones (Rohm, Royal), yes. Budget ones (Hyuduo, generic), no. They are sealed units. Once they start grinding, replace them.

Q: What is a “Bull Nose” Center?

A: Seen in the “Related Products” section of your file, a Bull Nose has a large, blunt cone. It is used for supporting pipes or tubing where a standard sharp point would fall inside the hole.