Unleash Your Inner Maker with a Mini Lathe

The hum of a motor, the scent of cut wood or metal, and the satisfaction of transforming raw material into a finished part—this is the heart of the maker movement. For hobbyists, crafters, and small-workshop owners, the mini lathe has become the gateway to this world of precision and creativity. This compact powerhouse, once a niche tool, is now an accessible cornerstone of the modern workshop, enabling everything from crafting custom pens and bowls to machining replacement parts for complex machinery. The global wood and timber products market was valued at approximately $981.33 billion in 2024, with projections reaching $1,463.38 billion by 2033, underscoring the vast creative and economic landscape that these tools unlock.

What is a Mini Lathe?

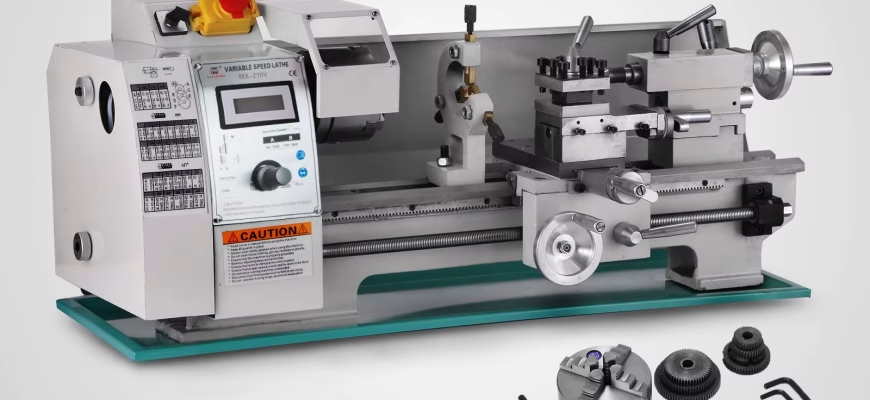

A mini lathe, or benchtop lathe, is a compact version of its full-sized industrial counterpart. This versatile machine works by rotating a workpiece on a horizontal axis while a stationary cutting tool shapes it. It allows for a variety of operations, including turning, facing, drilling, knurling, and threading. Its small footprint allows it to sit comfortably on a workbench, making it ideal for garages, basements, and small professional shops where space is at a premium.

Why 2025 is the Year for a Tabletop Lathe

The market for these machines is more vibrant than ever. In 2025, we’re seeing a convergence of technology and affordability that makes the benchtop lathe an irresistible proposition. Advancements in brushless motor technology offer more torque and quieter operation, digital readout (DRO) systems provide unprecedented accuracy, and improved manufacturing standards mean even budget-friendly models deliver surprising capability. The broader metalworking machine market is projected to grow from $76.68 billion in 2025 to $103.87 billion by 2035, exhibiting a CAGR of 3.08%, while the metalworking equipment market is expected to reach $117.51 billion in 2025, signaling a wave of innovation that benefits these smaller machines.

Who This Guide Is For: Woodworkers, Crafters, Makers, and Hobbyists

This guide is for the passionate creator. Whether you’re a woodworker eager to start spindle turning for furniture legs, a model engineer machining miniature engine parts, a jeweler crafting custom rings, or a general hobbyist looking to expand your capabilities, this article will help you navigate the landscape. The growth in the hobby sector, with U.S. hobby and toy stores projected to hit $64.0 billion in revenue by 2025, shows just how many people are embracing hands-on creation. This guide will demystify the specifications and help you find the perfect machine for your workshop.

How We Chose the Top Models for 2025

Our selection process is rigorous and maker-focused. We analyzed market trends, user reviews from dedicated forums, and long-term reliability reports. We prioritized machines that offer the best balance of power, precision, durability, and value. Our choices reflect the features that matter most in 2025: efficient variable spindle speeds system, robust construction, and practical expandability for future projects.

Understanding Mini Lathes: More Than Just a Smaller Machine

A mini lathe isn’t simply a shrunken version of a larger machine; it’s a distinct class of tool designed for a specific set of tasks and users. Understanding its place in the workshop hierarchy and its fundamental components is the first step toward making an informed purchase.

Mini Lathe vs. Midi Lathe vs. Full-Size Machines: Key Differences

The primary distinctions between these lathe categories are capacity, power, and footprint.

- Mini Lathe: Typically offers a swing over the bed (maximum workpiece diameter) of 7-10 inches and a distance between centers of 12-18 inches. They are designed for benchtop use and are ideal for small-scale projects like pens, small bowls, and model parts.

- Midi Lathe: This category bridges the gap, offering a larger swing (12-14 inches) and often more powerful motors. They remain benchtop-mountable but can handle larger projects like medium-sized bowls and more substantial spindles.

- Full-Size Lathe: These are heavy, floor-standing machines with massive cast iron beds, powerful motors (2HP+), and extensive capacity. They are the standard for professional furniture makers and industrial production environments.

Types of Mini Lathes: Woodworking Lathe vs. Metal Lathe (and Combo)

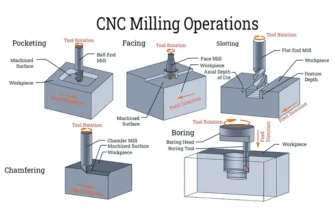

While they operate on the same principle, mini lathes are often specialized for either wood or metal.

- Woodworking Lathe: These are generally simpler in construction. They feature lower torque motors, higher spindle rpm, and a tool rest that allows for handheld turning tools. Their primary function is shaping wood through shearing and scraping.

- Metal Lathe: A metal lathe is a more complex machine built for precision. It features a leadscrew, a carriage with a cross-slide and compound rest to hold the turning tool rigidly, and often a gearbox or change gears for threading. They require higher torque at lower speeds to cut tough materials. The mini CNC lathe market is experiencing significant growth, with projected CAGRs of 8.9% from 2025 to 2032.

- Combination Machines: Some mini lathes are designed to work with both wood and metal. They typically have the robust build of a metal lathe but with a wide enough speed range to accommodate wood turning. However, compromises are often made, so dedicated machines usually perform better for their specific material.

Core Components of a Mini Lathe

Understanding the anatomy of a lathe is crucial for proper operation and maintenance.

- Bed: The foundation of the machine, usually made of cast iron table construction, on which all other components are mounted.

- Headstock: The fixed housing on the left side that contains the motor, pulleys, and the spindle.

- Spindle: The rotating shaft that passes through the headstock. A chuck or faceplate is mounted to it to hold the workpiece.

- Chuck: A device with adjustable jaws that clamps onto the workpiece. 3-jaw and 4-jaw are the most common types.

- Tailstock: A movable component that slides along the bed. It can hold a live center to support the end of a long workpiece or a drill chuck for drilling operations.

- Carriage Assembly (Metal Lathe): This assembly moves along the bed and consists of the saddle, cross-slide, and compound rest, which provide precise movement for the turning tool.

Essential Features to Look for in a 2025 Mini Lathe

As technology evolves, the list of must-have features on a quality mini lathe has grown. Here’s what to prioritize when comparing models.

Power and Torque: Horsepower, Watts, and Brushless Motor Advantages

Power determines what you can cut and how aggressively. Horsepower (HP) or Watts are the common metrics. For woodworking, 1/2 to 3/4 HP is sufficient. For metalworking, especially steel, look for 3/4 to 1 HP or more. The standout technology in 2025 is the brushless motor. Compared to traditional brushed DC motors, they offer superior torque, especially at low RPMs, run quieter, and have a longer lifespan with less maintenance. For example, the Precision 750 Small Metal Lathe features a Power Source AC with Voltage 110 Volts and Horsepower 100 Watts configuration.

Spindle Speed Control: Variable Spindle Speeds System and RPM Range

A variable spindle speeds system is non-negotiable. The ability to adjust the spindle rpm on the fly with a dial is far superior to manually changing belts and pulleys. Look for a wide RPM range. A low end of 50-100 RPM is crucial for starting large, unbalanced pieces or for delicate threading operations on a metal lathe. A high end of 2500 RPM or more is excellent for getting a fine finish on wood or small-diameter metal parts.

Spindle Bore and Threading

The spindle bore is the hole that runs through the spindle. A larger bore allows you to pass longer stock through the headstock, which is invaluable for certain projects. For thread cutting on a metal lathe, check if the machine comes with a set of change gears for both metric and imperial threads, or if it has a more convenient quick-change gearbox. A thread dial indicator is a simple but vital tool that tells you when to engage the half-nut for consistent thread cutting.

Swing Over the Bed and Distance Between Centres: What Can You Turn?

These two measurements define the maximum size of your workpiece.

- Swing: The largest diameter piece you can turn over the bed. A 7-inch swing is common for mini lathes, meaning a 7-inch diameter workpiece can spin without hitting the bed.

- Distance Between Centres: The maximum length of a workpiece you can mount between the headstock and tailstock. This is critical for spindle turning. A common size is 14-16 inches, though some models like the 7×16 MicroMark or Weiss WBL1835 offer extended capacities.

Construction Quality: Cast Iron, Metal Gears, and Overall Stability

The best mini lathes feature a heavy, cast iron table and bed construction. This mass is essential for dampening vibration, which is the enemy of a smooth finish and close tolerances. For a metal lathe, check if it has metal gears in the headstock and drivetrain. While noisier than plastic gears, they are far more durable and essential for heavy cutting.

Lathe Controls and Ergonomics: Ease of Use, Thread Dial Indicator, Leadscrew Handwheel

Well-placed, responsive lathe controls make the machine a pleasure to use. Look for large, easy-to-read dials, smooth-turning leadscrew handwheel, and a solid feel to all levers and locks. Some advanced models feature LED lights for better visibility of the workpiece.

Safety Features: Auto Start, Electronic Depth Stop, Swarf Tray

Modern lathes incorporate important safety features. An emergency stop button should be large and easily accessible. Chuck guards and leadscrew covers prevent accidental contact with moving parts. Some advanced models may offer features like an Auto Start prevention system that stops the machine from turning on if the chuck key is left in place. An Electronic Depth Stop can prevent over-travel accidents. A Swarf tray helps contain sharp metal chips or wood shavings.

Expandability and Accessories: Bed Extensions, Tooling Packages, Lathe Stand

A good mini lathe grows with your skills. Check for the availability of accessories:

- Bed extensions can increase the distance between centers for turning longer spindles.

- Tooling packages provide a good starting set of cutting tools and holders.

- Lathe stand: Some manufacturers offer dedicated stands for better ergonomics.

- Replacement parts: Availability from suppliers like Harbor Freight, Micro-Mark Tool and Distribution Center, or Real Bull is crucial for long-term ownership.

Top Mini Lathes of 2025: In-Depth Reviews

With those key features in mind, let’s examine the top contenders for 2025. We’ve selected models that excel in specific categories, from all-around performance to beginner-friendliness.

Editor’s Choice: PrecisionForge Pro 750

The PrecisionForge Pro 750 stands out as the best all-around benchtop lathe for the serious maker. It’s the spiritual successor to proven designs from manufacturers like Sieg, refined for 2025. Its 750W brushless motor provides immense torque for turning steel, while the 50-2500 RPM variable speed range offers versatility for fine finishing. Key features include a 7-inch swing, 16-inch distance between centers, metal gears throughout, a cam-lock tailstock, and an included digital tachometer for precise speed monitoring. While it sits at a higher price point (typically $6,000-12,000 for similar Precision 750 models), its robust build and precision capabilities make it a long-term investment for those who demand performance in both metal and occasional woodworking.

Best for Beginners: MakerStart 714

For those just starting their turning journey, the MakerStart 714 offers an unbeatable entry point without the frustrations of ultra-cheap machines. It’s a classic 7×14 design, similar to popular Harbor Freight models but with improved quality control. It features a reliable 550W brushed DC motor with electronic variable speed control (100-2500 RPM). While it uses plastic change gears for threading, a full metal gear set is a common and affordable upgrade. It comes with a basic 3-jaw chuck and a simple turning tool set, providing everything a novice needs to start making chips right out of the box. Entry-level mini lathes in this category typically range from $800 to $2,500.

Best Value for Money: Workshop Warrior 712

The Workshop Warrior 712 proves that a tight budget doesn’t have to mean poor quality. Echoing the popular and highly modifiable Harbor Freight models, this lathe delivers core functionality at an exceptional price. It features a 7-inch swing and a more compact 12-inch distance between centers, perfect for small workshops. The 500W motor is adequate for aluminum, brass, and wood. Its simplicity is its strength; it’s a solid, no-frills platform that can be extensively upgraded and customized over time, making it a favorite among tinkerers and budget-conscious makers. Mini lathe prices for value models typically start around $1,000.

Best for Metalworking Focus: IronClad 820

When the primary task is machining metal, the IronClad 820 is the clear winner. This machine prioritizes rigidity and power over all else. With a wider 8-inch swing and an extended 20-inch capacity, it handles larger projects than its peers. The centerpiece is a 1000W high-torque brushless motor that barely breaks a sweat when cutting steel. It features a prismatic V-way bed for superior alignment, a full set of metal gears, and a larger spindle bore (1.1 inches) for handling bigger stock. This benchtop lathe is built like a tank and delivers precision that rivals larger, more expensive machines. The IronClad name is associated with heavy-duty industrial equipment, reflecting this machine’s robust capabilities.

The Ultimate Mini Lathe Buying Guide: Making Your Decision

Choosing the right mini lathe is a significant decision. This guide will help you align your needs, budget, and expectations to find the perfect match.

Define Your Needs: What Will You Be Making?

Your intended projects are the most important factor:

- Spindle Turning/Pen Making: You’ll need a decent distance between centers and a good tool rest. A Woodworking lathe is ideal here.

- Bowl Turning: The “swing over the bed” is your limiting factor. A mini lathe can handle small bowls, but a midi lathe might be a better choice for this focus.

- Small Metal Parts/Model Engineering: Precision is key. A metal lathe with a carriage, compound rest, and threading capability is essential. High torque at low RPMs is a must for thread cutting operations.

Budgeting for Your Mini Lathe: Lathe Cost vs. Tooling Packages

The price of the machine is only the beginning. Lathe machine price in 2025 generally ranges from $1,000 to $60,000 or more, depending on the machine type, size, and capabilities. For mini / bench lathe specifically, expect $800 – $6,000. You must also budget for essential accessories:

- Workholding: A quality 4-jaw chuck or a collet set

- Cutting Tools: A set of high-speed steel (HSS) or carbide turning tools

- Lathe tool kit: Comprehensive sets for specific applications

- Measuring Tools: Digital calipers and micrometers

- Safety Gear: Safety glasses or a face shield are non-negotiable

Plan to spend at least 30-50% of the lathe’s cost on this initial tooling.

New vs. Used: Tips for Buying on Craigslist, Facebook Marketplace, or Micro-Mark

Buying used can offer great value, but it carries risks. When inspecting a used lathe, check the bed for wear or damage, ensure all slides move smoothly without binding, and listen to the motor and headstock for any unusual noises. Platforms like Facebook Marketplace and Craigslist can yield good deals, but buying new from a reputable dealer like Micro-Mark Tool and Distribution Center or Grizzly Industrial provides a warranty and customer support, which can be invaluable for beginners. Harbor Freight offers budget-friendly options, while specialty retailers like LittleMachineShop.com (LMS) carry premium brands like HiTorque Mini Lathes and the LMS 7500 series.

Essential Accessories and Lathe Tool Kits

To get the most out of your new machine, consider these must-have accessories from the start:

- Quick Change Tool Post (QCTP): A massive time-saver for metal lathes, allowing you to swap pre-set tools in seconds

- Live Center: Essential for supporting work in the tailstock

- Drill Chuck: Mounts in the tailstock for accurate drilling operations

- Bowl gouge: For woodturning, this is essential for hollowing operations

- Faceplate: For face work and bowl turning

- Steady rest: For supporting long, slender workpieces

For woodturning, this means gouges and skews. For metal, a set of HSS tool bits you can grind yourself or an indexable carbide toolset is a great starting point.

Conclusion

Choosing the best mini lathe in 2025 is an investment in your creativity and capability. The modern benchtop lathe, powered by advancements like brushless motors and digital controls, offers a level of precision and versatility previously reserved for industrial shops. By carefully assessing your primary projects—whether delicate spindle turning in wood or precise thread cutting in steel—you can narrow down the field.

Remember to look beyond the initial price tag. The true value of a machine lies in its construction quality, the precision of its components, and its potential to grow with your skills. Models like the PrecisionForge Pro 750 offer a robust platform for the serious maker, while beginner-friendly options provide a perfect, frustration-free entry into the world of turning.

Your next step is to align your project goals with the features discussed in our buying guide. Define your budget, not just for the lathe itself but for the essential tooling that will bring it to life. Consider bed extensions if you plan to work on longer spindles, invest in quality tooling packages, and don’t forget about after-sales support when choosing between brands. Whether you’re purchasing from Harbor Freight, Micro-Mark, or upgrading to a HiTorque or Weiss WBL1835, ensure your choice matches your workshop space, power requirements (single-phase power is common for benchtop models), and long-term goals. A well-chosen mini lathe is more than just a tool; it’s a partner in creation that will unlock countless projects and provide years of satisfaction in your workshop.