Why CNC Lathes Matter in Modern Manufacturing

In 2025, the manufacturing landscape is defined by a single, ruthless metric: efficiency per square foot. The modern CNC lathe machine is no longer just a tool for turning metal; it is a compact production cell capable of “done-in-one” manufacturing. With the rise of precision machining demands in sectors like aerospace and medical, the ability to hold micron-level tolerances while running unattended is what separates profitable job shops from those struggling to compete.

Unlike traditional manual lathes, today’s CNC turning centers leverage advanced servo motors, high-rigidity beds, and CNC automation to produce complex geometries with speed and consistency that human hands cannot match. Whether you are an OEM scaling up production or a job shop owner looking to replace aging iron, this guide is your blueprint. We will dissect the critical features, CNC lathe price tiers, and automation capabilities that drive ROI in the current market.

SECTION 1 — CNC LATHE FUNDAMENTALS

What Is a CNC Lathe Machine?

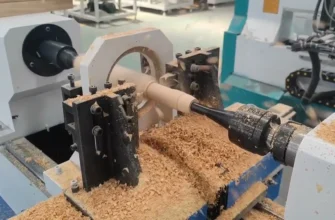

At its core, a CNC lathe machine (Computer Numerical Control lathe) is a subtractive manufacturing tool that rotates a workpiece—typically a cylindrical bar—against a stationary cutting tool. While the concept mirrors ancient pottery wheels, the execution is pure high-tech engineering.

- The Beginner’s View: Think of it as a robotic sculptor. You clamp a metal rod into a spinning chuck, and a computer tells a sharp tool exactly where to shave off material to create a bolt, a shaft, or a chess piece.

- The Expert’s View: It is a highly rigid machine tool utilizing 2 or more axes of motion (X and Z) to generate cylindrical features. Modern CNC turning centers often include “live tooling” (milling capabilities), allowing for off-center drilling, tapping, and milling in a single setup.

Key Differences: Manual vs. NC vs. CNC

- Manual Lathe: Operator controls every movement via handwheels. High skill, low repeatability.

- NC (Numerical Control): Precursor to CNC; read punch cards. Obsolete.

- CNC Lathe: Fully digital. Uses G-code programs, CAD/CAM integration, and feedback loops to correct errors in real-time.

How a CNC Lathe Works: Step-By-Step

Understanding the workflow helps in selecting the right machine configuration:

- Motion Control: The controller sends signals to servo motors, which drive ball screws. These screws move the tool turret along linear guideways or box ways with micron-level precision.

- Workholding & Spindle: The spindle is the heart of the lathe. It grips the material using a chuck or collet and rotates it at speeds ranging from 2,000 to 12,000+ RPM.

- Cutting: The turret indexes the correct tool (e.g., an OD turning tool or ID boring bar) and engages the material.

- Programming: The machine follows G-code instructions, often generated by CAM software, to execute complex toolpaths like threading, contouring, and facing.

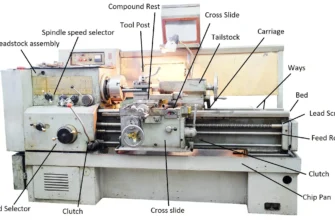

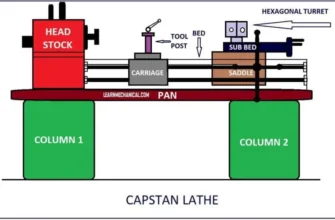

Core Components of a CNC Lathe

- Bed and Guideways: The foundation. A heavy cast-iron slant bed offers superior vibration damping and chip evacuation compared to flatbed designs.

- Spindle and Chuck: Determines maximum bar capacity and cutting speed. High-quality spindles use ceramic bearings to minimize thermal expansion.

- Turret: The tool changer. Standard turrets hold 10-12 tools. Live tooling turrets have powered stations for milling cutters.

- CNC Controller: The brain. Common ecosystems include Fanuc (industry standard), Haas (user-friendly), Siemens (high-end contouring), and Mitsubishi.

- Automation Interfaces: Ports and logic to connect robotic arms, bar feeders, or parts catchers for lights-out production.

SECTION 2 — TYPES, CAPABILITIES & PRECISION LEVELS

Types of CNC Lathes and Their Best Applications

- 2-Axis CNC Lathe: The workhorse. Handles O.D. (Outer Diameter) and I.D. (Inner Diameter) turning, facing, and drilling on the center line. Ideal for washers, bolts, and simple shafts.

- 3-Axis CNC Lathe: Adds a “C-axis” to the spindle, allowing it to index precisely. This enables simple milling features like hex heads or bolt hole circles on the face of the part.

- 4-Axis CNC Lathe: Features a Y-axis. This allows the tool to move up and down (off-center), enabling complex milling of pockets and keyways on the side of a cylinder.

- Multi-Axis Turning Centers (5–9 Axis): These machines often have dual spindles (main and sub) and B-axis milling heads. They can transfer a part from one spindle to the other automatically, machining all sides in one go.

- Swiss-Type CNC Lathes: Specialized for long, slender parts (under 32mm diameter). The material slides through a guide bushing, keeping the cutting action close to the support. Critical for medical screws and watch parts.

- Vertical CNC Lathes (VTL): The spindle sits vertically. Gravity helps clamp large, heavy rings or flywheels that would be difficult to mount on a horizontal lathe.

Precision Metrics: What Makes a CNC Lathe More Accurate?

Not all “precision” is created equal. When buying, look at these specs:

- Repeatability vs. Accuracy: Accuracy is hitting the bullseye once. Repeatability is hitting the same bullet hole 1,000 times. High-end lathes boast repeatability of ±0.00004″ (1 micron).

- Thermal Stability: As a machine runs, friction generates heat, causing the metal frame to expand. Brands like Okuma use “Thermo-Friendly” concepts to electronically compensate for this growth, maintaining tight tolerances all day.

- Spindle Runout: The amount of “wobble” in the spindle. Premium machines have runout under <0.5 microns.

- Linear Guides vs. Box Ways: Linear guides are faster (good for light duty), while box ways are slower but offer immense rigidity for cutting tough alloys like Inconel.

SECTION 3 — FEATURES, AUTOMATION & SMART TECHNOLOGIES

Key Features to Look for in a High-Precision CNC Lathe

- Spindle Torque: High horsepower isn’t enough. You need torque at low RPMs for cutting steel and titanium. Look for 2-speed gearboxes in heavy-duty models.

- Turret Index Speed: How fast can it swap tools? Slow tool changes add up to hours of lost time per month.

- Control Connectivity: Modern controls should have Ethernet, USB, and MTConnect capability for data monitoring.

- Chip Management: Often overlooked. A programmable tailstock and a high-pressure coolant system (1,000 PSI) are mandatory for deep hole drilling and breaking stringy chips.

Automation Capabilities: What Today’s CNC Lathes Can Do

CNC automation is no longer a luxury; it is a survival strategy for the labor shortage.

- Bar Feeders: The simplest form of automation. Loads 12-foot bars into the spindle automatically.

- Robotic Loading (Tending): A robot arm picks raw “slugs” from a bin, loads the chuck, and removes finished parts.

- Tool Presetters: An arm that touches the tool tip to measure its length and wear automatically. This eliminates test cuts and manual data entry errors.

- Lights-Out Machining: Combining a bar feeder, parts catcher, and fire suppression system allows the machine to run unattended overnight.

- Predictive Maintenance: AI sensors monitor spindle vibration to predict bearing failure before it crashes your machine.

SECTION 4 — COMPARISONS, BRANDS & MODELS

Best CNC Lathe Machines for Precision Machining (Top Picks)

#1: Multitasking Turning Center for Aerospace

Model: Mazak INTEGREX i-200S

- Why: A 5-axis beast with a milling spindle that tilts. It can machine a complex turbine blade or landing gear component in a single setup.

- Best Feature: “Done-in-One” capability reduces fixture errors.

#2: Mid-range CNC Lathe for General Machining

Model: Haas ST-30Y

- Why: The ubiquitous choice for job shops. Affordable, easy to find operators for, and the Y-axis allows for decent milling work.

- Best Feature: The Haas Control is the most user-friendly in the industry.

#3: Swiss-Type CNC for Medical & Micro Parts

Model: Citizen Cincom L32-XII

- Why: The gold standard for Swiss machining. It features “LFV” (Low Frequency Vibration) technology that breaks chips into dust, preventing bird-nesting on tiny titanium parts.

- Best Feature: Unmatched reliability for 24/7 small-part production.

#4: High-Torque Heavy Duty Lathe

Model: Doosan (DN Solutions) PUMA 2600SY

- Why: Built like a tank. It uses box ways for maximum rigidity, making it perfect for turning hard steels and cast iron in the oil & gas sector.

- Best Feature: Incredible vibration damping and heavy material removal rates.

#5: Budget-Friendly CNC Lathe for Small Shops

Model: Tormach 15L Slant-PRO

- Why: An entry-level machine that runs on single-phase power. Perfect for prototyping or garage startups.

- Best Feature: Accessible price point (<$25k) with real CNC capability.

Price Comparison: How Much Do CNC Lathes Cost?

- Entry-Level ($20,000 – $50,000): machines like Tormach or older used Haas models. Good for education, prototyping, or simple fittings.

- Mid-Range Turning Centers ($60,000 – $150,000): The sweet spot. Includes new Haas ST series, basic Doosan/DN Solutions, and Okuma Genos L series. Includes live tooling and tailstocks.

- High-End Multitasking ($150,000 – $500,000+): Mazak Integrex, DMG Mori NLX, Nakamura-Tome. These are dual-spindle, multi-turret factories in a box.

- Automation Bundles: Adding a bar feeder costs ~$10k–$15k. A robotic tender cell can add $30k–$80k depending on complexity.

CNC Lathe Brand Comparison: Strengths & Weaknesses

- Haas:

- Pros: Excellent support, high resale value, easy to learn.

- Cons: Less rigid than Japanese brands; lighter duty cycles.

- Okuma:

- Pros: Legendary mechanical quality, proprietary OSP control is powerful.

- Cons: Steep learning curve, expensive parts.

- Mazak:

- Pros: Mazatrol conversational programming is the fastest way to program at the machine. Huge lineup.

- Cons: Service can be hit-or-miss depending on the local distributor.

- Doosan / DN Solutions:

- Pros: Best “bang for the buck.” Very rigid machines at a competitive price.

- Cons: Controls can feel generic (standard Fanuc).

- Citizen / Star:

- Pros: The undisputed kings of Swiss machining.

- Cons: Extremely complex to program; specialized for small diameters only.

SECTION 5 — INDUSTRY USE CASES

Applications of CNC Lathe Machines

- Aerospace Components: Landing gear struts, hydraulic valves, and fasteners requiring exotic alloys like Inconel and Titanium.

- Automotive & EV: Drive shafts, pistons, and complex EV motor housings. High volume, low cycle time is key.

- Medical Devices: Bone screws, dental implants, and surgical instruments. Requires Swiss-type lathes for <5mm diameters.

- Oil & Gas: Large drill bits, couplings, and valves. Requires heavy-duty, high-torque machines with large bore capacities.

- Job Shops: The “do-it-all” environment. Requires versatile machines (like a Y-axis lathe) that can switch from aluminum to steel in minutes.

Real-World Examples: Parts Best Made on CNC Lathes

- Shafts & Pins: The classic lathe part. Speed and concentricity are unbeatable.

- Threaded Components: CNC lathes can single-point thread any custom pitch, tapered threads (NPT), or multi-start threads.

- Bushings & Bearings: High precision ID turning ensures tight interference fits.

SECTION 6 — BUYER’S GUIDE

How to Choose the Right CNC Lathe for Your Business

- Define Part Geometry: If your parts are under 1.25″ diameter and long, buy a Swiss. If they are 10″ diameter slugs, buy a chucker.

- Tolerance Requirements: Do you need ±0.005″ or ±0.0002″? Don’t buy a supercar to drive to the grocery store, but don’t buy a go-kart for the racetrack.

- Materials: Cutting Aluminum? High RPM (10,000+) is better. Cutting Stainless? Low-end torque and box ways are better.

- Automation Needs: If you have orders for 5,000+ pieces, a bar feeder is mandatory.

- Total Cost of Ownership: Factor in tooling holders ($5k+), software (Mastercam/Fusion 360), and power hookups, not just the machine sticker price.

Common Questions About CNC Lathes (FAQ)

How does a CNC lathe differ from a regular lathe?

A CNC lathe is automated and driven by computer code, allowing it to move multiple axes simultaneously and cut complex curves (interpolation) that are impossible by hand.

What industries require the highest machining accuracy?

Aerospace and Medical. A failure in an aircraft engine part or a spinal implant is catastrophic, so traceability and micron-level precision are non-negotiable.

Are CNC lathes better than CNC mills?

They are different. Lathes are for cylindrical parts; mills are for prismatic (blocky) parts. However, a “turn-mill” center can do 80% of what a mill does, often more efficiently for round stock.

What skills do operators need?

Operators need to understand G-code reading, precision measurement (micrometers/calipers), and basic trigonometry. Setup machinists need deeper knowledge of tooling, workholding logic, and troubleshooting.

What accuracy can modern CNC turning centers achieve?

Standard machines hold ±0.0005″. High-end machines with thermal compensation and glass scales can hold ±0.0001″ or better in production.

SECTION 7 — MAINTENANCE, TRAINING & FUTURE TRENDS

Maintenance Tips for Maximum Precision

- Warm-Up Cycles: Never run a cold spindle at max RPM. Run a 10-minute warm-up program to stabilize thermal expansion.

- Lubrication: Check way lube daily. A dry guideway will destroy accuracy in hours.

- Spindle Checks: Measure runout and clamp force annually. A losing grip reduces accuracy and is a safety hazard.

- Cleanliness: Chips are the enemy. Keep sensors and limit switches clear of debris.

Future Trends in CNC Lathe Machining

- Smart Manufacturing / Industry 4.0: Machines that text you when they finish a job or detect a broken tool.

- Autonomous Machining Cells: Robots on rails tending multiple lathes, inspecting parts with vision systems, and packing them for shipment without human touch.

- Hybrid Machines: Lathes that can 3D print metal onto a part and then turn it down to size (Additive + Subtractive) for repairing expensive components.

Choosing a CNC Lathe That Scales With Your Business

Selecting the best CNC lathe is a balancing act between three points: Precision, Price, and Automation.

If you chase the lowest price, you sacrifice rigidity and tool life. If you ignore automation, you cap your revenue potential. The winners in the next decade of manufacturing will be those who view their lathes not just as machines, but as autonomous profit centers.

Whether you need a Swiss-type for medical screws or a heavy-duty turning center for oil field pipe, the technology exists to make your shop world-class. Define your niche, calculate your ROI based on CNC automation potential, and invest in the best iron you can afford. Your future tolerances depend on it.