For modern machine shops, the difference between a profitable run and a scrap pile often comes down to the rigidity, repeatability, and thermal stability of their turning center. This guide covers the top-rated precision CNC metal lathe machines of 2025, analyzing the automation capabilities, accuracy metrics, and controller technologies that define industrial machining today.

What Is a Precision CNC Metal Lathe?

A precision CNC metal lathe is a computer-controlled turning center designed to remove material from rotating metal workpieces with micron-level accuracy (often ±0.0001” or better). Unlike manual lathes, which rely on operator dexterity, CNC (Computer Numerical Control) lathes utilize pre-programmed code to control servo motors, ensuring that every pass is identical to the last.

In industrial production, “precision” is not just about hitting a dimension once; it is about repeatability—the machine’s ability to hold tight tolerances (e.g., ±5 microns) over thousands of parts despite thermal expansion and tool wear. For sectors like aerospace and medical device manufacturing, this consistency is the primary requirement.

How Precision CNC Lathes Work

CNC Control System & Programming Logic

The “brain” of the machine, the controller (such as Fanuc, Siemens, or Haas), translates G-code into electrical signals. In 2025, advanced controllers now feature “digital twin” technology, allowing machinists to simulate the entire cutting process in 3D to prevent crashes before a single chip is cut.

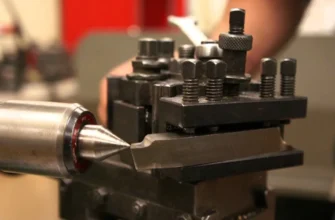

Servo Motors, Drives & Closed-Loop Feedback

Unlike stepper motors found on hobbyist machines, industrial CNC lathes use high-torque AC servo motors with closed-loop encoders. This system constantly communicates the axis position back to the controller. If cutting forces push the tool out of position by even a fraction of a micron, the drive system instantly compensates to maintain accuracy.

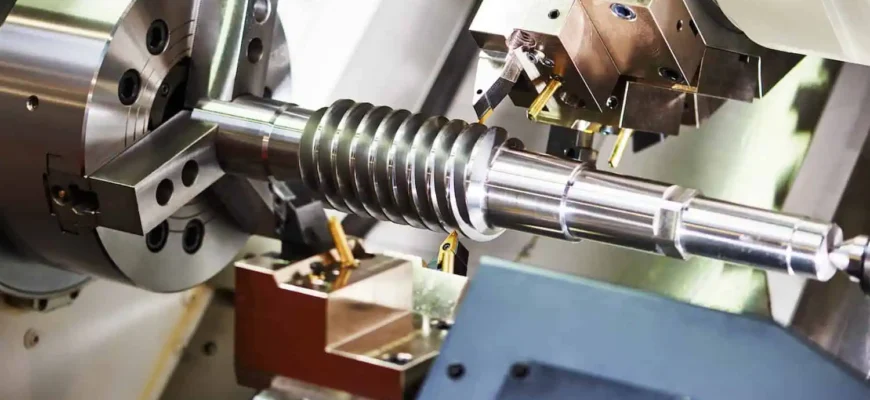

Tool Turrets, Live Tooling & Multi-Axis Turning

Modern CNC turning centers replace the simple tool post with a servo-driven turret holding 12–24 tools. “Live tooling” allows the turret to spin milling cutters, drills, and taps, effectively turning the lathe into a multitasking machine that can machine complex geometries (like hex heads or cross-holes) in a single setup.

Spindle Speed Control & Thermal Stability

The spindle is the heart of the lathe. High-precision models use chilled liquid cooling jackets to maintain a constant temperature, preventing “thermal drift” that causes dimensions to wander as the machine warms up.

Metal Turning Workflow

The process follows a digital thread:

- CAD: The part is designed in 3D software (SolidWorks, Fusion 360).

- CAM: Toolpaths are generated, defining speeds, feeds, and tool changes.

- Post-Processing: The generic toolpaths are converted into specific G-code for the machine’s controller.

- Machining: The CNC lathe executes the code, producing the finished part.

Key Features of a High-Precision CNC Metal Lathe

Multi-Axis Turning (2-Axis, 3-Axis, 4-Axis, 5-Axis)

While a standard 2-axis lathe cuts in X and Z, a 3-axis lathe adds a C-axis (spindle indexing) for milling. A 4-axis machine typically adds a Y-axis for off-center drilling, and 5-axis or dual-spindle machines can transfer parts between spindles to machine both ends simultaneously.

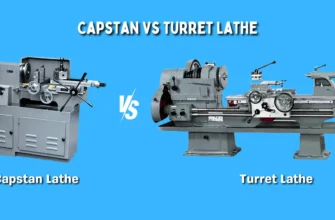

Turret Type (Servo Turret, Power Turret, Live Tooling)

Servo-driven turrets index faster and clamp harder than hydraulic versions. Live tooling turrets (often BMT or VDI style) are essential for “Done-in-One” production, eliminating the need to move parts to a mill.

Ball Screws, Linear Guides & Rigidity

- Linear Guides: Use recirculating ball bearings for high speed and low friction. Best for aluminum and light finishing passes.

- Box Ways: Metal-on-metal sliding surfaces (hand-scraped) with an oil film. They offer superior vibration damping and rigidity, making them the standard for heavy-duty cutting of steel, titanium, and Inconel.

CNC Controller Technologies

- Fanuc: The industry standard for reliability; widely used but has a steeper learning curve.

- Siemens (840D): Dominates in 5-axis and complex multi-tasking; features excellent conversational programming.

- Haas: Known for user-friendliness; the “Visual Programming System” is ideal for rapid setup.

- PathPilot (Tormach): An open, approachable control system gaining traction in prototyping labs.

Benefits of Using Precision CNC Metal Lathes

- Ultra-High Accuracy: Capable of holding tolerances as tight as ±0.0001” (2.5 microns) for critical bearing fits.

- Consistency in Large-Scale Production: Automated bar feeders and robotic loaders allow machines to run unattended (“lights-out”), producing identical parts 24/7.

- Lower Scrap Rate: Simulation features and probe verification drastically reduce human error and wasted material.

- Industry 4.0 Integration: Modern lathes feed data to cloud dashboards, alerting managers to tool wear or maintenance needs in real-time.

Top-Rated CNC Metal Lathe Machines (2025)

Best Overall Industrial CNC Lathe: Haas ST-20Y

The Haas ST-20Y is the workhorse of job shops globally. It strikes a perfect balance between price, performance, and usability.

- Specs: 12″ max turning diameter, 21″ cutting length, 4,000 RPM spindle.

- Why it wins: The addition of the Y-axis and live tooling allows for single-setup machining of complex parts. The Haas control is incredibly intuitive, reducing training time for new operators.

Best for High-Precision Small Parts: Citizen Cincom L20

For parts under 20mm diameter (like medical screws), the Citizen L20 Swiss-type lathe is unbeatable.

- Key Feature: “Low Frequency Vibration” (LFV) technology breaks chips into microscopic pieces, preventing “bird-nesting” on stringy materials like plastic or stainless steel.

- Ideal For: Medical implants, electronics connectors, and watch parts.

Best Large-Capacity CNC Turning Center: Okuma LB3000 EX III

When rigidity is paramount, the Okuma LB3000 EX III stands out with its slant-bed box way construction.

- Capabilities: High-torque PREX motor and “Thermo-Friendly Concept” that compensates for heat growth, maintaining accuracy even during heavy roughing cuts.

- Best For: Automotive shafts, oil and gas fittings, and hard turning applications.

Best Entry-Level CNC Metal Lathe: Tormach 15L Slant-PRO

For small shops or garage startups, the Tormach 15L offers real CNC capability at a fraction of the cost.

- Specs: 15″ swing, 3,500 RPM, 3 HP spindle.

- Pros: Runs on single-phase power and uses the easy-to-learn PathPilot controller. It’s a perfect stepping stone from manual machining to CNC.

Best CNC Lathe for Prototyping: Haas TL-1

The Haas TL-1 (Toolroom Lathe) bridges the gap between manual and CNC.

- Design: Open bed design with electronic handwheels allows operators to use it manually for quick one-off repairs or fully automated for small batches.

- Flexibility: No enclosure means easy access for measuring and setup, making it ideal for R&D labs.

CNC Metal Lathe Comparison Table (Specs & Performance)

| Feature | Haas ST-20Y | Okuma LB3000 EX III | Citizen L20 (Swiss) | Tormach 15L |

|---|---|---|---|---|

| Best For | General Job Shop | Heavy Duty / Hard Turning | Micro Precision | Entry Level / Education |

| Construction | Linear Guide | Box Way (Slant Bed) | Linear Guide | Cast Iron Slant Bed |

| Spindle Speed | 4,000 RPM | 5,000 RPM | 10,000 RPM | 3,500 RPM |

| Control | Haas NGC | OSP-P500 | Mitsubishi/Cincom | PathPilot |

| Accuracy | ±0.0002″ | ±0.0001″ (Thermal Comp) | ±0.0001″ | ±0.0005″ |

| Live Tooling | Yes (Y-Axis) | Yes (M-Spindle) | Yes (Gang Tooling) | No (Optional Turret) |

| Price Range | $85k – $110k | $120k – $160k+ | $100k – $140k | $25k – $35k |

CNC Lathe Automation for Industrial Production

Bar Feeders & Gantry Loaders

Automation starts with material handling. Bar feeders push long stock through the spindle bore, enabling continuous production of small parts. For larger slugs or castings, gantry loaders (robotic arms mounted inside the machine) load and unload parts automatically, reducing cycle time.

In-Process Probing & Tool Monitoring

Modern lathes use touch probes (like Renishaw) to measure parts inside the machine. If a dimension is drifting, the controller automatically updates the tool offset. Load monitors also sense if a tool is dull or broken by detecting spikes in spindle motor load, pausing the machine to prevent crashes.

How to Choose the Right CNC Metal Lathe

Production Volume & Part Complexity

- High Volume (10,000+ parts): Requires a fast machine with a bar feeder and aggressive rapids (e.g., Swiss lathe or linear guide turning center).

- High Complexity: Parts with off-center holes or flats require a Y-axis and live tooling to avoid secondary operations.

Metal Type

- Aluminum/Brass: Linear guide machines are superior due to their high speed.

- Titanium/Inconel/Steel: Box way machines (like the Okuma) are necessary to absorb the vibration and cutting forces without chattering.

Budget vs Long-Term ROI

While a Tormach or used machine costs less upfront ($30k), a production machine like a Mazak or Haas ($100k+) often pays for itself faster through higher feed rates, better tool life, and higher resale value.

Real-World Applications of Precision CNC Turning

- Aerospace: Landing gear bushings and turbine engine components requiring heat-resistant superalloys.

- Medical: Titanium bone screws and surgical instruments, typically machined on Swiss-style lathes.

- Automotive: Transmission shafts and pistons where high-volume repeatability is critical.

- Oil & Gas: High-pressure valves and fittings made from tough stainless steel.

Maintenance Tips to Sustain High Precision

- Warm-Up Cycles: Always run a spindle warm-up program to thermally stabilize the headstock before cutting close-tolerance parts.

- Lubrication: Check way lube levels daily. Running a CNC machine dry will ruin expensive linear guides or box ways in hours.

- Alignment Checks: After a crash or every 6-12 months, check the turret alignment and headstock taper to ensure they are perfectly square to the Z-axis.

- Software Updates: Keep the controller firmware updated to access the latest motion control algorithms and bug fixes.

Innovations & Future Trends in CNC Turning

- AI-Assisted Machining: Controllers that “learn” from vibration patterns to automatically adjust feed rates for optimal surface finish.

- Digital Twins: Exact virtual replicas of the machine allow shops to quote jobs accurately and prove out code without taking the physical machine out of production.

- Hybrid CNC: Machines that combine additive manufacturing (3D printing metal) and subtractive turning in a single unit to create geometries impossible with turning alone.

Choosing a High-Precision CNC Metal Lathe for 2025

Selecting the right precision CNC metal lathe is a balance of current needs and future growth. For prototyping and light production, a versatile toolroom lathe or entry-level slant bed offers the best value. However, for industrial manufacturers chasing “lights-out” efficiency and ±0.0001″ tolerances, investing in a rigid, automation-ready turning center with a Y-axis is the only path to staying competitive. Prioritize rigidity for hard metals, speed for aluminum, and always ensure your chosen machine has a local service network to keep your spindle turning.