Why CNC Wood Lathes Dominate Professional Woodturning

In 2025, a CNC wood lathe machine is no longer a luxury for serious woodturners and furniture makers – it is the new standard. Shops that still rely only on manual lathes struggle to compete with the speed, repeatability, and labor savings of modern CNC woodturning systems, especially in markets pressured by low-cost, high-volume production. Studies on upgrading conventional furniture workshops to CNC wood lathes have shown productivity increases of around 37% and visibly smoother, more precise surfaces compared to manual turning.

Several trends explain why CNC wood lathes dominate in 2025:

- Automation of repetitive work: Once a program is created, the machine can repeat legs, balusters, or bats with identical dimensions for hours, with minimal operator input.

- Precision and surface quality: CNC turning with properly chosen carbide inserts can achieve low surface roughness, even on hard exotic timbers, when parameters and tool geometry are optimized.

- Labor cost pressure: A single operator can supervise multiple machines or parallel processes (turning + sanding + carving) instead of standing at one manual lathe all day.

Newer 2024–2025 models go beyond basic 2‑axis turning. They incorporate closed‑loop servos, multi-station spindles, automatic loading hoppers for blanks, and even combined turning / milling / carving / sanding centers where a column can be fully processed in one clamping.

At the high end, machine tool research is moving toward AI-based optimization of cutting parameters, vibration control, tool wear prediction, and bed structure design, all of which gradually trickle down into woodworking CNCs.

(IMAGE SUGGESTION: Modern production line with multiple CNC wood lathes turning table legs and balusters.)

What Is a CNC Wood Lathe? (Beginners + Pros Explained)

A CNC wood lathe is a computer-controlled woodworking machine that rotates a wood blank and moves cutting tools automatically along programmed paths. Instead of the operator manually holding chisels, a controller interprets G‑code or CAD/CAM toolpaths and drives motors on each axis.

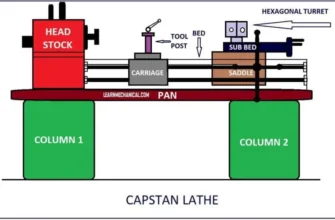

Working principle & core components

Typical core components of a CNC wood lathe machine include:

- Bed & frame: Heavy cast-iron or steel bed for rigidity, vibration damping, and accuracy.

- Headstock with drive spindle: Rotates the workpiece; often powered by 3–5.5 kW motors with inverter-controlled variable speed up to 3,000+ rpm for turning, and higher speeds (up to ~18,000 rpm) on dedicated carving/milling spindles.

- Tailstock (often pneumatic): Supports the other end of the workpiece and clamps blanks quickly.

- X / Z axes (and extra axes where available): Driven by ball screws or helical racks with stepper or servo motors for precise linear motion along and across the workpiece.

- Tool slides and toolposts: Hold one or more turning tools, planers, carving spindles, sanding heads, and saw blades, sometimes all on the same machine.

- Controller: DSP handheld controllers or PC‑based CNC controls interpret G‑code and coordinate all movements.

Servo vs stepper systems

Modern CNC wood lathes use either stepper motors or servo motors:

- Stepper-based systems

- Servo-based systems

- Closed‑loop feedback improves positioning accuracy and eliminates lost steps.

- Better at high feed rates and for multi-function composite centers handling turning, milling, carving, and sanding on the same part.

- Preferred for complex profiles, high surface-quality requirements, and multi-station industrial lathes.

Research on high‑precision CNC machine tools shows that servo-driven feed systems with optimized dynamic design achieve higher speeds and better accuracy than traditional static designs, which directly benefits modern CNC wood lathes.

Single-axis vs multi-axis vs 5-axis woodturning

- Single-axis CNC wood lathe:

- One turning axis (Z) and a single tool moving along/into the workpiece.

- Ideal for simple profiles like cylinders, cones, and basic spindles.

- Lower cost and easier programming.

- Dual- or multi-tool / 2–3 axis lathes:

- 3-axis & 4-axis hybrid turning + carving lathes:

- 5-axis machining centers:

- Still rare and expensive in pure woodworking lathes, but concepts from 5-axis metal lathes are influencing premium composite woodturning centers.

Typical products a CNC wood lathe can produce

A CNC wood lathe machine can produce both functional and decorative parts at scale, including:

- Table and chair legs

- Staircase balusters and newel posts

- Bed posts and columns

- Baseball bats and training clubs

- Pool cues and similar sporting goods

- Sofa and bun feet, lamp posts, bannisters

- Bowls, vases, and turned craft items (with appropriate chucking)

- Beads, pens, toys, and small custom decor (on mini or benchtop lathes)

(IMAGE SUGGESTION: Diagram labeling headstock, tailstock, toolpost, X/Z axes on a CNC wood lathe.)

Types of CNC Wood Lathes in 2025

1. Single-Knife CNC Wood Turning Lathes

These machines use one main turning tool to shape the workpiece and are popular among small shops and custom furniture producers.

- 1 station, 1 tool, machining sizes like 1500 × 300 mm (L × D).

- Turning speeds up to around 3,000 rpm for spindle motors around 3–4 kW.

- Ideal for low-to-medium batch production of legs, posts, and spindles.

Best for:

- Small furniture shops needing repeatability but not huge volume.

- Custom balusters, bed posts, and artistic columns.

- Users moving from manual to their first CNC wood lathe machine.

2. Dual-Knife & Multi-Tool CNC Wood Lathes

These lathes mount two turning knives (often roughing + forming) and sometimes additional tools such as drilling or carving heads.

Advantages:

- Roughing tool removes the bulk quickly, while the forming tool makes a light finishing pass, which improves surface finish and consistency.

- Higher throughput without a massive price increase compared to single-knife models.

Key industries:

- Furniture factories doing table legs, chair legs, and sofa components.

- Stair-part manufacturers producing thousands of balusters and posts.

- Sports-equipment shops producing baseball bats or clubs.

3. Multi-Spindle CNC Wood Lathes

Multi-spindle CNC wood lathes mount multiple workpieces at once (often 2–4) and turn all of them simultaneously, multiplying throughput.

- 2–4 spindles or stations, each with its own centers and tools.

- Production capacity 2–4× that of a single-spindle lathe.

- Particularly suited to standardized long runs with minimal variation.

Typical users:

- Cue factories turning pool cues and similar straight, precise rods.

- High-volume table leg or baluster producers.

- OEM component suppliers who need identical parts in large quantities.

4. CNC Wood Lathes with Engraving / Carving

Hybrid machines combine turning and high-speed carving/milling in a single setup. They are equipped with:

- One or more turning tools for the core profile.

- A 3–4 axis carving spindle (up to ~18,000 rpm) for milling flutes, grooves, text, or ornamental patterns.

Use cases:

- Ornamental columns with relief carvings, twisted designs, or complex fluting.

- Decorative furniture elements, newel posts with carved motifs.

- Sculptural work where turning defines the basic form and carving adds detail.

5. Automatic Loading CNC Wood Lathes

Automatic-loading lathes integrate:

- Material hoppers that hold many blanks.

- Automatic centering, clamping, turning, and unloading sequences.

- Fully programmed cycles that repeat the same pattern continuously.

A typical automatic-loading wood lathe with a hopper and saw head is used to produce:

- Stair balusters and newel posts

- Table legs, bed rails, baseball bats

- High-volume turned components for furniture lines

By eliminating manual loading, these machines provide significant ROI in mass-production environments where labor is a major cost driver.

6. Mini CNC Wood Lathes (Hobby & Small Business)

Mini CNC wood lathes and benchtop models are compact and relatively affordable options for:

- Craftspeople making beads, pens, toys, bowls, and small decor.

- Small studios and home workshops with limited space.

Example specs from a mini benchtop CNC wood lathe:

- Turning diameter: 5–100 mm

- Max turning length: 400 mm

- Processing precision: 0.01 mm

- Compact footprint and ~260 kg weight for small shops

Price ranges from about a few hundred dollars for simple manual/DIY minis up to around 3,000–5,000 USD for fully CNC mini lathes with automatic feeding.

(IMAGE SUGGESTION: Side-by-side photo of a full-length industrial CNC wood lathe and a mini benchtop CNC lathe.)

Top CNC Wood Lathe Machines to Buy in 2025 (Expert Picks)

The models below are categories reflecting what’s on the market in 2025, illustrated with real-world specifications from major manufacturers such as STYLECNC, Catek, EagleTec, BCAMCNC, and others.

1. Best Overall: 7‑in‑1 Multifunction CNC Wood Lathe (2025 Edition)

This category represents multi-function composite machining centers that combine up to seven processes in a single clamping:

- Turning

- Facing

- Milling

- 3–4 axis carving

- Drilling

- Sanding / brushing

- Automatic loading/unloading

A typical machine in this class (e.g., a multifunctional CNC wood lathe and turning–milling composite center) may offer:

- Processing length: 1500–3000 mm

- Max diameter: 250–300 mm

- Spindle / turning motor: 4–5.5 kW turning motor, plus 3–4 kW carving spindle up to 18,000 rpm

- Axes: 3–4 coordinated axes + indexing spindle

- Functions: Turning, milling, carving, planing, sanding in one machine

Pros:

- One clamping for multiple operations → top-grade accuracy and alignment.

- Massive reduction in handling time and setup.

- Ideal for complex columns, furniture legs with mortise-and-tenon, carved posts, and premium stair parts.

Cons:

- Higher purchase price (commonly from ~10,000 to 18,000 USD, depending on configuration).

- Programming is more complex; usually requires solid CAD/CAM workflows.

Ideal users:

- Professional furniture factories producing high-value, heavily ornamented pieces.

- Custom stair and architectural millwork shops.

- Production studios where each part must be fully finished off the machine.

2. Best Budget CNC Wood Lathe for Small Shops

Budget CNC wood lathes focus on core turning performance without advanced automation.

- Turning capacity: 1500 × 300 mm (L × D)

- 1 axis, 1 cutter or 2 cutters

- 3–4 kW turning motor with frequency inverter

- Stepper-driven X/Z axes with ball screw or rack

- Manual loading, basic DSP or PC-based controller

Price range: Approximately 3,000–6,000 USD for base CNC turning lathes with simple tooling, depending on region and configuration.

Pros:

- Affordable entry into CNC woodturning.

- Capable of professional accuracy and finish for most furniture parts.

- Good learning platform for shops moving up from manual machines.

Cons:

- Manual loading and limited automation reduce throughput.

- Fewer built-in operations (often turning only).

3. Best CNC Lathe for Table Legs & Furniture Production

Furniture manufacturers typically favor 1500–3000 mm length and 250–300 mm diameter capacity, with at least dual tools and sometimes an extra carving spindle.

Key specs to look for:

- Spindle power: 4–5.5 kW turning motor.

- Stations: 1–2 stations depending on volume.

- Axes: 2–3 axes (Z, X, and sometimes carving axis).

- Features: Heavy cast-iron bed, automatic tool retract, optional copying or profiling modes.

Typical price: Roughly 4,500–10,000 USD for mid-range production lathes of this size.

4. Best CNC Pool Cue Lathe (Professional Level)

Professional cue makers need extreme straightness, balance, and surface finish.

A high-level cue-production CNC wood lathe will feature:

- Multi-spindle or multi-station designs to turn 2–4 cues at once.

- Long bed (over 1500 mm) with precise guidance.

- Rigid cast bed and quality linear guides / ball screws to avoid runout.

- Optional high-speed carving / milling for logos and decorative inlays.

Multi-spindle lathes can increase output several times versus single-spindle, which is ideal for cue or dowel-type products.

5. Best CNC Wood Lathe for Baseball Bat Production

Some manufacturers offer specialized baseball bat CNC lathes designed for long, tapered workpieces. Example specs from a dedicated CNC baseball bat lathe:

- Turning length: 100–1500 mm

- Diameter range: 20–160 mm

- Two axes and two cutters per axis for efficient roughing and finishing

- 4.0 kW turning motor, 0–3000 rpm range

Such machines are optimized for high-volume bat production and similar long rods (balusters, pillars, and nunchakus).

6. Best CNC Wood Carving + Turning Hybrid Lathe

If a shop needs both structural turning and ornamental carving, a hybrid turning + carving lathe is often best.

Typical features:

- CNC turning for the base form.

- 3–4 axis high-speed carving spindle to engrave patterns, fluting, or relief work.

- The carving head may share a servo with other tools but is switched by solenoid-actuated cylinders.

When to choose a combo machine:

- When each part must leave the machine fully finished (no secondary carving station).

- When complex curved-leg designs require both planing and carving in one setup.

- When decorative stair and column work is a core profit center.

7. Best Mini CNC Wood Lathe for Crafts & Gifts

Mini CNC lathes stand out for compactness and affordability, yet still provide professional results on small projects.

Example mini CNC wood lathe specs:

- Turning diameter: 5–100 mm

- Max turning length: 400 mm

- Precision: 0.01 mm

- 1.5 kW motor and built-in automatic drilling option

These machines are ideal for:

- Crafts, toys, and small decor (beads, pens, necklaces, small bowls).

- Small online shops producing personalized gifts.

- Makers who need CNC repeatability in a small apartment or micro workshop.

Specs Comparison Table — 2025 CNC Wood Lathe Models

The table below consolidates representative specifications from real CNC wood lathes, including mini, single-tool, dual-knife, and multifunctional models.

(Values are representative ranges from current manufacturer catalogs and listings, not a single specific model.)

Best CNC Wood Lathe Manufacturers in 2025

Top Chinese CNC Wood Lathe Manufacturers

- STYLECNC

- Offers a full line of CNC wood lathes, from mini benchtop (STL0410) to long-bed 2530 series with max turning length 3000 mm and diameter 300 mm.

- Provides automatic feeding lathes and all‑in‑one turning + carving machines with multi-axis capability.

- Strong focus on stair parts, furniture legs, and creative project ideas.

- Catek CNC

- Specializes in fully automatic multifunction CNC wood lathes and mini to industrial turning centers.

- Offers mini lathes for just over 3,000 USD, mid-size 1516 and 1510 models around 4,000–8,000 USD, and large multifunction centers up to ~18,000 USD.

- Emphasis on modular functional modules (turning tools, planers, milling cutters, saw blades, sanding devices, automatic loading systems).

- EagleTec CNC

- BCAMCNC

- Other Chinese sources (general)

Leading Western Brands

Most Western premium brands (Laguna, Powermatic, Oneway, Robust Tools) focus on high-end manual or semi-digital woodturning lathes rather than full CNC, but they are crucial benchmarks for build quality, ergonomics, and support.

- Powermatic

- Known as the “Gold Standard” of woodworking machinery.

- Models like the 3520C and 4224B offer 2–3 HP motors, heavy cast-iron beds (700+ kg), variable-speed drives, digital RPM readouts, and ergonomic controls.

- While primarily manual, their engineering level is a reference for rigidity and vibration damping.

- Oneway

- Robust Tools

These Western brands are excellent benchmarks for quality, and their machines remain ideal for manual and semi-automated turning. For fully automated CNC wood lathes, most buyers still turn to specialized Chinese and Asian manufacturers in 2025.

What Sets Premium Manufacturers Apart

When comparing CNC wood lathe manufacturers, key differentiators include:

- Warranty & support: Clear warranty on mechanical and electronic parts (often 1–3 years) plus reliable remote diagnostics and spare-part availability.

- Controller technology: Modern, user-friendly controllers with good G‑code compatibility and CAD/CAM support.

- Servo & drive quality: Branded servos/steppers, ball screws, and linear guides with good documentation.

- Bed and frame design: Heavily ribbed cast beds and optimized joint surfaces improve dynamic stiffness and reduce vibration.

- Documentation & training: Good manuals, video tutorials, and training packages reduce ramp-up time drastically.

CNC Wood Lathe Prices in 2025 — Full Breakdown

Entry-Level Models (Approx. 1,800–5,000 USD)

- Mini CNC wood lathes for crafts and small items.

- Basic single-knife CNC turning lathes with 1500 × 300 mm capacity.

What you get:

- Stepper motors, basic DSP controllers, manual loading.

- Adequate precision for small businesses and serious hobbyists.

- Limited automation (no automatic loading, fewer tools).

Mid-Range Professional Lathes (Approx. 4,000–12,000 USD)

Covers most production-grade furniture and stair-part lathes, such as:

- Dual-knife lathes (1530 and similar).

- Automatic-loading models with simple hoppers.

- Hybrid turning + basic carving machines with one carving spindle.

You typically get:

- 4–5.5 kW main motors, 1500–3000 mm length capacity.

- More robust beds, industrial-grade controllers.

- Better fixtures for quick part changeover and longer duty cycles.

Industrial Multi-Station Lathes (~12,000–20,000+ USD)

- Multi-spindle CNC wood lathes with 2–4 spindles.

- Fully automatic multi-function composite centers for turning, carving, planing, and sanding.

Real-world prices for advanced composite CNC wood lathes and multi-station machines reach up to about 18,000 USD, and high custom configurations can exceed that depending on options, automation, and brand.

Extra Costs Buyers Forget (Must Include)

When budgeting for a CNC wood lathe machine, remember hidden or indirect costs:

- Shipping & customs: Freight, insurance, import duties, and customs brokerage.

- Taxes & local fees: VAT, sales tax, and local certification/inspection where applicable.

- Tooling & consumables: Carbide turning tools, inserts, drill bits, sanding wheels, saw blades.

- Chucks & fixtures: Four-jaw chucks, steady rests, special centers for bowls or short parts.

- Software: CAD/CAM packages (if not already owned).

- Dust collection: Industrial dust extractors or centralized systems to protect electronics and health.

- Installation & training: On-site setup or paid remote training, especially for advanced multi-function machines.

- Air supply: Compressors for pneumatic tailstocks, tool actuators, and automatic loaders.

How to Choose the Right CNC Wood Lathe (Decision Framework)

1. Business Type

- Furniture maker / stair shop:

- Cue maker:

- Bat manufacturer:

- Craft shop or custom studio:

2. Production Volume Requirements

- Low volume / custom: Single-knife CNC wood lathe with manual loading is usually sufficient.

- Medium volume: Dual-knife or two-station models significantly reduce cycle time.

- High volume: Multi-spindle and automatic-loading lathes maximize throughput while minimizing labor.

3. Material Types (Softwood / Hardwood / Exotic Woods)

Harder woods (oak, ebony, rosewood, etc.) require:

- Rigid beds and high-quality guides to avoid chatter.

- Correct insert geometry and tip radius for smooth surface finishes.

- Adequate spindle torque at lower speeds.

If you frequently machine dense hardwoods or large diameters, avoid underpowered, lightweight machines.

4. Needed Accuracy & Finish Requirements

- For standard furniture legs and balusters, standard CNC wood lathes already meet common tolerances.

- For high-precision cues or decorative art pieces, look for:

- Closed-loop servos.

- Higher-positioning accuracy and stable frame design.

- Tooling optimized for fine surface roughness.

5. Automation Level

Decide how much of the workflow should be automated:

- Manual loading only.

- Automatic tailstock clamping and tool retract.

- Automatic feeding and loading with hopper/robotic arms.

- Fully multi-process machining centers (turning + carving + sanding).

Higher automation means higher initial cost but lower cost per part in production.

6. Budget & ROI Calculation

To estimate ROI:

- Determine current labor time per part on manual lathes.

- Compare with expected cycle times on candidate CNC machines (vendor can often provide examples).

- Factor in scrap reduction from better repeatability.

- Include tooling, maintenance, and energy costs.

- Estimate payback time: a well-selected CNC wood lathe often pays for itself in 1–3 years in a busy shop.

CNC Wood Lathe Features to Look for in 2025

Key features that distinguish top 2025 machines:

- Closed-loop servo technology:

- Essential for high-speed, high-precision applications and multi-function machines.

- Automatic tool setters & multi-tool turrets:

- Touchscreen controllers & friendly UI:

- Dust protection & safety enclosure:

- Remote monitoring / IoT capabilities:

- Vibration-free bed structure:

- Multi-station productivity:

CNC Wood Lathe Applications (Real-World Use Cases)

Real production examples include:

- Table legs & chairs: Straight and curved legs, stretchers, and decorative elements.

- Staircase balusters & newels: From simple round profiles to twisted and carved designs.

- Bed posts & columns: Long, heavy parts that benefit from rigid, high-capacity lathes.

- Pool cues: Precision-turned cues with tight tolerances.

- Baseball bats: High-volume production on dedicated CNC bat lathes.

- Decorative columns & architectural features: Including fluting, spiral patterns, and relief carvings (on hybrid machines).

- Sculptures & carved art: Combined turning and carving workflows.

- Bowls, vases, and small craft items: Especially with chucking systems and mini lathes.

(IMAGE SUGGESTION: Collage of finished products—balusters, table legs, bats, bowls—labeled as CNC-turned.)

Maintenance & Daily Care Checklist

Regular maintenance is critical for accuracy and machine life:

- Lubrication points:

- Grease or oil ball screws, linear guides, and bearings per manufacturer schedule.

- Verify central lubrication systems (if present) are functioning.

- Spindle care:

- Avoid overloading; monitor spindle temperature and noise.

- Keep belts tensioned correctly and inspect for wear.

- Servo / stepper alarms & troubleshooting:

- Check alarm codes on the controller and follow vendor procedures.

- Inspect wiring, connectors, and encoder/limit-switch cleanliness.

- Alignment checks:

- Periodically verify tailstock alignment with headstock (simple test cuts or dial indicators).

- Check tool height and offset to maintain surface finish and diameter accuracy.

- Cleaning routine:

- Remove chips and dust daily, especially from rails, screws, and control cabinets.

- Use compressed air with caution (prefer vacuum + dust extraction).

Common Problems & How to Fix Them

Typical issues and solutions:

- Vibration issues:

- Chatter marks / poor surface finish:

- Servo / stepper errors:

- Inspect for overloads or binding on axes.

- Check for dirt or chips on rails and ballscrews.

- Verify encoder cables and connectors.

- Dimensional inaccuracies:

- Recalibrate work offsets and tool lengths.

- Inspect backlash in screws or play in linear guides.

- Ensure blanks are properly centered and clamped.

- Tool alignment issues:

- Re-square toolholders and verify cutting edges are on centerline.

- Check for deflection in long, slender tools and use appropriate rests.

FAQs — CNC Wood Lathe Machine (FAQ Schema Style)

Q1: How accurate are CNC wood lathes?

Well-built CNC wood lathes routinely achieve sub‑0.1 mm dimensional repeatability, and specialized mini machines can specify 0.01 mm precision on small parts. Actual accuracy depends on machine rigidity, drives, tooling, and setup quality.

Q2: Can CNC lathes make pool cues and table legs?

Yes. CNC wood lathes are widely used for pool cues, table legs, balusters, and similar long, slender parts. Dedicated cue and bat lathes or standard 1500–3000 mm turning lathes handle these applications daily in production.

Q3: What size CNC lathe do I need?

Choose a machine that comfortably covers your longest part + some margin and the maximum anticipated diameter. Furniture and stair shops often choose 1500–3000 mm length and ~300 mm diameter, while craftspeople may be fine with 400–600 mm mini lathes.

Q4: Do CNC wood lathes work with hardwoods?

Yes, as long as the machine is rigid and properly tooled. Research on CNC turning of hardwoods shows that tool geometry (especially tip radius) and cutting parameters strongly influence surface roughness. Many production lathes are specifically used for oak, beech, and other hardwood furniture components.

Q5: How long do cutters last?

Tool life depends on wood species, feed/speed, and insert quality. Carbide inserts used in CNC turning can maintain acceptable surface finish for long runs when correct cutting parameters are used, and AI-based wear prediction is increasingly used in metal machining to optimize tool life. In woodturning, frequent inspection and replacement once finish deteriorates is recommended.

Q6: Is 4-axis worth it for woodturning?

If you only produce simple cylindrical parts, no. For ornamental columns, twisted legs, and carved surfaces, a 3–4 axis hybrid turning + carving machine is worth the investment, because it completes complex shapes in one clamping.

Suggested Internal & External Links (SEO Enhancements)

Internal link ideas (on your site):

- “CNC Router vs CNC Wood Lathe: Which Machine Do You Need?”

- “Beginner’s Guide to G‑Code for Woodworking”

- “Dust Collection Systems for CNC Woodworking Shops”

- “How to Price Custom Woodturning Projects”

External authority link ideas (without URLs):

- Official product and knowledge pages from STYLECNC, Catek CNC, EagleTec CNC, and BCAMCNC.

- Technical research articles on CNC lathe design, dynamics, and tool wear from peer-reviewed engineering journals for advanced readers.

(When publishing, link the anchor text to the appropriate manufacturer or journal page.)

Conclusion — The Future of CNC Woodturning Beyond 2025

The CNC wood lathe machine has transformed woodturning from a manual craft into a scalable, data-driven manufacturing process. In 2025, the combination of automatic loading, multi-tool stations, and hybrid turning + carving capabilities makes it possible to produce intricate, repeatable wood components at speeds that manual lathes cannot match.

Looking ahead:

- AI-assisted machining: Expect wider adoption of AI models that optimize cutting parameters, predict tool wear, and stabilize vibration – trends already active in CNC metal machining and being adapted to wood.

- Advanced automation: More shops will deploy multi-spindle, fully automatic centers that manage loading, turning, carving, sanding, and unloading with minimal human intervention.

- Smarter, greener shops: Better dust collection, energy-efficient drives, and integrated monitoring will make CNC woodturning both safer and more sustainable.

For professional woodworkers, furniture manufacturers, and ambitious hobbyists, the key is choosing a CNC wood lathe aligned with real business needs: part sizes, materials, production volume, and design complexity. With a solid selection framework and careful vendor comparison, the right machine can become the core asset that powers profitable, future-ready woodturning well beyond 2025.