Key Highlights

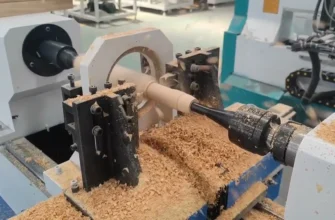

- Lathe tools are essential for shaping materials like metal and wood with precision.

- Tool materials like High-Speed Steel (HSS) and carbide offer different benefits for various cutting tasks.

- Key operations include turning, facing, and parting, each requiring a specific tool.

- Proper tool holders, including quick-change systems, enhance efficiency and versatility.

- Beginners can benefit from starter kits that bundle essential tools and accessories.

- Regular maintenance and proper storage are crucial for extending tool life and ensuring quality work.

Introduction

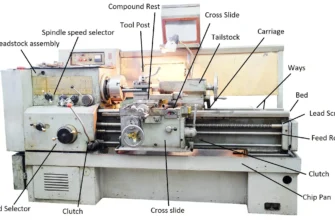

Welcome to the world of precision machining! If you work with a lathe, you know that the quality of your finished product depends heavily on the tools you use. A metal lathe is a powerful machine, but it’s the cutting tools that do the delicate work of shaping and refining your workpiece. Choosing the right tools is the first step toward achieving the exact specifications and smooth finishes that define high-quality work. This guide will walk you through the essential tools you need for precision projects.

Essential Machinist Lathe Tools for Precision Work

To get started in metalworking with a lathe, you need a basic set of lathe tools. These tools are designed for specific cutting operations that range from removing large amounts of material to creating fine details. The most fundamental tasks you’ll perform are turning, facing, and parting, and each requires a specialized tool to get the job done right.

Having the right tooling and accessories not only makes your work easier but also ensures the precision you need. As you build your collection, you’ll discover a variety of tools that expand your capabilities. Understanding their differences is key to mastering the craft. Let’s explore some of the most important tool types and their specific functions.

High-Speed Steel (HSS) and Carbide Tool Bits: Differences and Uses

When selecting cutting tools for your lathe machine, the two most common materials you’ll encounter are High-Speed Steel (HSS) and carbide. HSS is known for its versatility and durability, making it a favorite for general-purpose turning and custom jobs. It can withstand high temperatures without losing its sharpness, and it’s relatively easy to sharpen.

Carbide tools, on the other hand, are significantly harder than HSS and can maintain their cutting edge for much longer. This makes them ideal for high-volume production and for cutting tough materials. While HSS is great for its adaptability, carbide excels in situations where speed and longevity are the priority. The choice between them often depends on the material you are cutting and the scale of your project.

| Feature | High-Speed Steel (HSS) | Carbide |

|---|---|---|

| Hardness | Durable and versatile | Significantly harder, holds edge longer |

| Best Use | General turning, softer materials, custom work | Hard materials, high-volume production |

| Cost | More cost-effective for small jobs | Higher initial cost, but cost-efficient for long runs |

| Sharpening | Can be easily re-sharpened by hand | Requires specialized grinding wheels |

Turning, Facing, and Parting Tools: Key Functions Explained

Among the wide array of tools available for a metal lathe, three types perform the most fundamental operations: turning, facing, and parting. Each one has a distinct purpose in shaping a workpiece. Understanding their functions is the first step to creating accurate and well-finished parts.

Turning tools are the workhorses of the lathe, used to reduce the diameter of a workpiece and shape its external profile. Facing tools are designed to create a flat, smooth surface on the end of the workpiece. Finally, parting tools are thin, blade-like tools used to cut off a finished section of the material from the main stock.

- Turning Tools: Used for cutting along the length of the workpiece to reduce its diameter.

- Facing Tools: Designed to machine the end of a workpiece to make it perfectly flat.

- Parting Tools: Used to slice through the workpiece to separate a finished part.

Choosing the Right Lathe Cutting Tools and Tool Holders

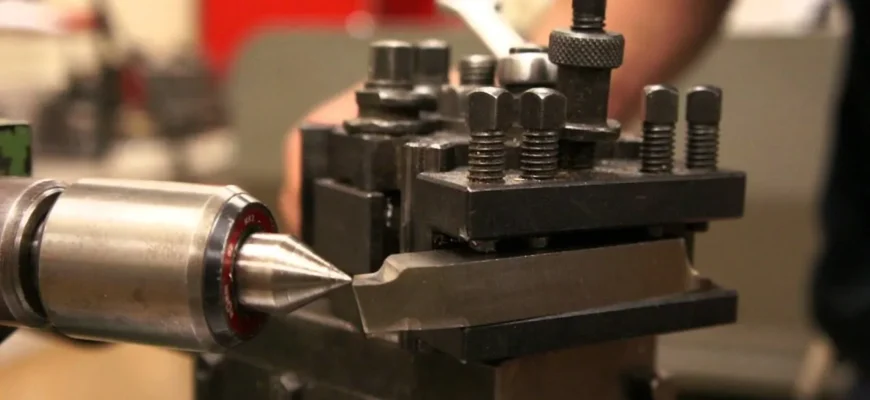

Selecting the right cutting tool is only half the battle; you also need the correct tool holder to support it. The holder is what secures the cutting tool to the lathe’s turret or tool post, and a solid setup is critical for preventing vibration and ensuring a clean cut. The right combination of tooling and holders provides the stability needed for precision work.

Modern systems like an indexable lathe turning tool or a quick change tool post offer incredible versatility and efficiency. These setups allow you to swap out cutting tools or inserts quickly, minimizing downtime and letting you move seamlessly between different operations. As we explore further, you’ll see how these components work together.

Understanding Tool Holders, Posts, and Quick-Change Systems

A tool holder is the vital link between your cutting tool and your lathe. Its job is to hold the tool securely in the tool post, ensuring it remains rigid during cutting. Traditional posts require you to manually adjust the tool height with shims, but modern systems have made this process much simpler and more accurate for any home workshop.

Quick-change tool post systems are a game-changer for efficiency. These systems, like the popular Aloris style, use dovetail-locking holders that allow you to swap pre-set tools in seconds. This means you can switch from a turning tool to a boring bar without having to re-measure and adjust the tool height each time, which offers incredible versatility.

- Improved Efficiency: A quick change tool system drastically reduces the time it takes to switch between different cutting operations.

- Enhanced Rigidity: These systems provide a very secure and rigid mount for your tools, which improves surface finish and accuracy.

Selecting Insert Types and Tool Materials for Metalworking

When working with an indexable lathe turning tool, choosing the right insert is just as important as selecting the tool holder. These replaceable inserts come in various shapes, sizes, and materials, each designed for a specific purpose in metalworking. Carbide inserts are extremely popular due to their hardness and long life, especially in CNC machining.

The material of your workpiece is the most important factor in your selection. For hard materials like stainless steel, a coated carbide insert is often the best choice. For softer materials like aluminum, a sharp, uncoated carbide or HSS tool may work better. The geometry of the insert also matters, as different shapes are better suited for roughing, finishing, or profiling.

- Workpiece Material: Match the insert material (carbide, ceramic, etc.) to the hardness of the metal you are cutting.

- Machining Operation: Choose an insert geometry designed for the task, whether it’s heavy material removal or fine finishing.

Must-Have Lathe Tool Sets and Starter Kits for Beginners

If you’re just starting, the sheer number of lathe tools and accessories can feel overwhelming. This is where starter kits come in handy. A good kit provides a foundational set of tools that allows you to tackle a wide range of basic projects right away. These packages are a cost-effective way to build your initial tooling collection.

These sets typically include a variety of essential lathe tools, such as turning, facing, boring, and threading tools. By investing in a comprehensive starter kit, you can experiment with different operations and learn what works best for your needs before purchasing more specialized accessories. Let’s look at what makes a good kit and where to find one.

Recommended Starter Kits for Hobbyists and Home Workshops

For hobbyists and those with home workshops, a well-rounded starter kit is the perfect entry point into lathe work. When shopping for a kit, look for one that includes a variety of tool types. A good set will typically contain tools made from both HSS and carbide, giving you the flexibility to work with different materials and learn the strengths of each.

The best starter kits offer a selection of tools for common operations. This way, you can practice everything from basic turning and facing to more complex tasks like threading or creating grooves. Many online retailers offer these kits with convenient shipping options, making it easy to get everything you need delivered to your door.

- Variety of Tools: A good starter kit should include tools for turning, facing, boring, and parting.

- Mix of Materials: Look for a set that offers both HSS and indexable carbide tools to cover a range of applications.

Tips for Sourcing Quality Lathe Tools and Accessories in the United States

Finding high-quality lathe tools and accessories is essential for achieving great results. While many options are available, it’s important to source your tools from reputable suppliers. Look for online stores that specialize in metalworking equipment, as they often have knowledgeable staff who can offer advice and recommendations.

When purchasing online, read reviews from other machinists to get a sense of a tool’s quality and performance. Don’t forget to check the supplier’s shipping policies and return options. Besides basic cutting tools, you will eventually need other accessories like mandrels, drill chucks, and threading dies, so finding a one-stop shop can be very convenient.

- Consult Experts: When in doubt, seek advice from experienced machinists or technical representatives from tool manufacturers.

- Check Reviews: Customer reviews can provide valuable insight into the real-world performance of lathe tools and accessories.

Maintaining and Troubleshooting Your Machinist Lathe Tools

Your lathe tools are an investment, and proper maintenance is the key to protecting them. Good care and regular cleaning not only extend the life of your tools but also ensure they continue to deliver the precision you need. Neglecting maintenance can lead to poor surface finishes, inaccurate cuts, and even damage to your workpiece.

Knowing how to troubleshoot common issues is another important skill. This includes recognizing the signs of a worn-out tool so you can replace or sharpen it before it affects your work. The following sections will provide some practical tips for tool care and identifying when a tool needs attention.

Proper Care, Storage, and Cleaning Techniques

Proper care for your lathe tooling starts with cleaning after every use. Metal chips and cutting fluid can cause rust and corrosion if left on the tools. A quick wipe-down with a cloth and a light coat of oil can prevent this and keep your tools in top condition. This simple step is one of the easiest ways to protect your investment.

Storage is another critical aspect of tool care. Never just toss your tools into a drawer where they can knock against each other. This can chip or dull the delicate cutting edges. Instead, use a dedicated tool rack or a storage box with dividers to keep your lathe accessories organized and protected.

- Clean After Use: Always wipe down your tools to remove chips and fluid, then apply a light layer of protective oil.

- Store Safely: Keep tools in a dedicated rack or organized box to prevent cutting edges from getting damaged.

How to Spot Worn-Out or Damaged Lathe Tools

Knowing when your lathe cutting tools are worn-out is crucial for maintaining quality. One of the first signs of a dull tool is a poor surface finish on your workpiece. If you notice the finish is getting rougher or you see burnish marks, it’s likely time to inspect your tool. Another indicator is if you need to apply more force to make a cut.

Visually inspect your cutting edges regularly. Look for any signs of chipping, cracking, or a rounded-over edge where it should be sharp. For indexable inserts, a worn-out edge can simply be rotated to a fresh one. For HSS tools, a trip to the grinder for a quick sharpening is usually all that’s needed to repair the edge.

- Poor Surface Finish: If your cuts are no longer smooth, your tool is likely dull or damaged.

- Visible Edge Wear: Check for chipped, rounded, or cracked cutting edges.

Conclusion

In summary, having the right machinist lathe tools is essential for achieving precision and excellence in your work. From understanding the differences between high-speed steel and carbide tool bits to knowing how to maintain your tools, each aspect plays a crucial role in your machining success. By investing in quality lathe tools, selecting the appropriate cutting techniques, and practicing proper maintenance, you will not only enhance your craftsmanship but also ensure the longevity of your tools. Remember, a well-equipped workshop leads to more efficient and enjoyable projects. Happy machining!

Frequently Asked Questions

What are the most essential machinist lathe tools for precision work?

The most essential lathe tools are turning, facing, and parting tools, as they handle the primary shaping of a workpiece. Beyond these, a good set of boring bars for internal work and basic accessories like a drill chuck and live center are fundamental for achieving precision in a wide range of projects.

Is carbide better than high-speed steel for metal lathe cutting?

Neither is universally “better”; it depends on the job. Carbide is harder, lasts longer, and excels at cutting hard materials at high speeds, making it great for production. High-speed steel is more versatile, tougher, and easier to sharpen, making it ideal for custom work and softer materials on a metal lathe.

Where can I buy reliable machinist lathe tools and tool kits online?

You can find reliable lathe tools and kits from specialized online metalworking suppliers. It’s wise to read customer reviews and compare products before buying. Look for companies with transparent shipping policies and good customer support. Sourcing from reputable brands ensures you get quality accessories for your workshop.