Herbert Capstan & Turret Lathes

In the pantheon of British engineering, few names command as much respect as Alfred Herbert Ltd. For over a century, the Coventry-based firm was not merely a manufacturer; it was the backbone of the industrial revolution’s second wave. While the company produced a vast array of tooling, it is the Herbert Capstan and Turret Lathes that remain the most enduring symbols of their legacy.

These machines were the workhorses of the 20th century. From the frantic munitions production of two World Wars to the booming automotive industry of the post-war era, Herbert lathes turned raw metal into the components that mechanized the world. Unlike the standard “center lathe” found in a hobbyist’s garage, Herbert machines were designed for one purpose: repeatability. They allowed operators to produce identical parts in rapid succession without stopping to measure or change tools for every cut.

Today, these industrial heritage machines hold a unique place in the market. They are sought after by preservationists, model engineers, and job shops that value rigidity over modern CNC complexity. Understanding the Herbert lathe is not just about learning mechanics; it is about understanding the evolution of mass production itself.

Origins & Evolution of Herbert Lathes

Foundation of Herbert Ltd

The story begins in the late 19th century in Coventry, the heart of the UK’s engineering sector. Alfred Herbert founded the company in the late 1880s, initially to produce boiler tubes, but quickly pivoted to machine tools. By realizing that the manufacturing industry needed better tools to keep up with demand, Herbert positioned his company to become, at its peak, the largest machine tool organization in the world.

The company’s growth trajectory mirrored the industrialization of the West. By the onset of WWII, Herbert Ltd was essential to the Allied war effort, churning out thousands of lathes to produce shell casings, aircraft fuses, and vehicle parts. This period cemented the brand’s reputation for “bombproof” build quality—machinery designed to run 24 hours a day, seven days a week.

Shift from Manual to Semi-Automatic Systems

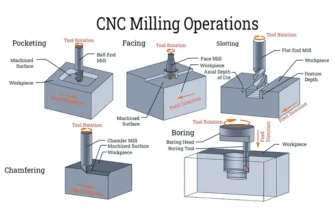

The early 20th century saw a critical shift in manufacturing philosophy. The traditional engine lathe required a skilled turner to manipulate every cut. Herbert led the charge in democratizing precision. By developing robust capstan and turret systems, they allowed semi-skilled operators to achieve tolerances that previously required a master craftsman.

This era introduced “production tooling.” Instead of a single tool post, Herbert lathes featured multi-station turrets. This meant a drill, a boring bar, a turning tool, and a die head could all be set up once. The operator simply had to index the turret to the next station. This shift from manual manipulation to semi-automatic cycling reduced cycle times from hours to minutes.

Transition Toward Robot-Assisted Machines (Herbert 2M/3M Auto Robot)

As the 1960s bled into the 1970s, the demand for automation surged. Before the full dominance of Computer Numerical Control (CNC), there was a bridge technology: the plug-board automatic. The Herbert 2M and 3M Auto Robot lathes represent this fascinating transitional era.

These machines utilized pneumatic cylinders and electrical solenoids controlled by a physical plug-board system. Engineers would physically place pins in a matrix board to program the sequence of operations—slide forward, rapid retract, turret index, spindle stop. While primitive by modern software standards, the Auto Robot series was revolutionary for high-volume operations, allowing one operator to tend multiple machines simultaneously.

What Are Capstan & Turret Lathes?

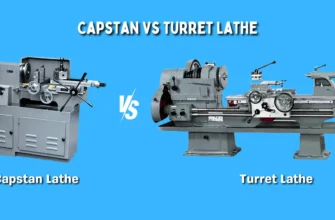

While the terms are often used interchangeably by laymen, there is a distinct engineering difference between a capstan lathe and a turret lathe.

Capstan Lathe Definition

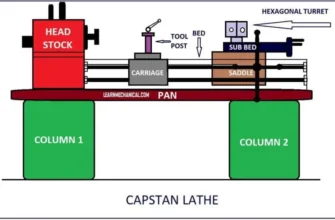

A capstan lathe (often referred to as a ram-type lathe in the US) features a hexagonal tool turret mounted on a slide (ram), which in turn slides within a saddle clamped to the bed. When the operator rotates the “star wheel” handle, the ram moves forward to engage the work. When retracted, the turret automatically indexes to the next tool.

Capstans are designed for speed. Because the moving mass (the ram) is lighter than the whole saddle, they are faster to operate and less fatiguing. They are ideal for small-to-medium batch production of smaller components like studs, pins, and bushings.

Turret Lathe Definition

A turret lathe (saddle-type) is the heavy-duty cousin. Here, the hexagonal turret is mounted directly onto a massive saddle that slides along the main bedways of the lathe.

Because there is no secondary “ram,” the turret lathe is significantly more rigid. It handles heavy interruptions in cutting and large-diameter workpieces. However, moving the entire saddle requires more physical effort or mechanical assistance, making these machines slower but far more powerful than capstans.

Key Differences (Capstan vs Turret)

- Rigidity: Turret lathes are more rigid because the tool holder is mounted directly to the main saddle. Capstan rams have “overhang” when extended, which can introduce vibration on heavy cuts.

- Speed of Operation: Capstan lathes are faster for short-stroke work.

- Workpiece Size: Turret lathes generally handle larger chucking work and longer shafts.

- Tooling Capacities: Turret lathes usually accept larger shank tooling and heavy boring bars.

The Herbert Machine Lineup: Key Models Explained

Herbert No. 2D Capstan Lathe

If there is one machine that defines the genre, it is the Herbert No. 2D. It is arguably the most popular capstan lathe ever made. Compact yet incredibly capable, the 2D was a fixture in technical colleges and factories alike.

Its defining feature was the “Duo-Rate” cross slide and the highly versatile turret system. The 2D was famous for its “Chipstream” box tools, which allowed for high-speed turning of steel with a finish that looked like it had been ground. It typically handled bar stock up to 1.5 inches diameter and was the standard for manufacturing fasteners and small shafts.

Herbert 2M & 3M Auto Robot Capstan Lathes

The “M” series marked the integration of pneumatics. The 2M and 3M Auto Robots were based on the iron of the manual machines but stripped of handwheels. Instead, they featured air cylinders driving the slides and a large electrical cabinet housing the logic cards.

These machines featured automatic bar-feeding mechanisms. Once a 10-foot length of steel was loaded, the machine would cycle continuously—feeding, turning, drilling, parting off, and repeating—until the bar was consumed. They also introduced safety guards with interlocks, a feature less common on earlier manual models.

Herbert 4D, 5, and Larger-Frame Turret Lathes

Moving up the scale, the Herbert No. 4 (Senior and Preoptive models), No. 7, and No. 9 were the heavyweights. These were true turret lathes.

The “Preoptive” headstock was a marvel of mechanical engineering. It allowed the operator to select the next desired spindle speed via a dial while the machine was currently cutting. Once the cut was finished, the operator simply pulled a lever, and the gearbox instantaneously shifted to the pre-selected speed via friction clutches. This saved massive amounts of time during complex operations involving widely varying diameters.

Mechanical Design & Engineering Characteristics

Construction & Materials

Herbert lathes are renowned for their Flamard beds. This was a proprietary process where the cast iron bed ways were flame-hardened and precision ground. This resulted in bearing surfaces that were exceptionally resistant to wear and scoring. Even today, a 70-year-old Herbert often retains the original scraping marks on its ways, a testament to this metallurgy. The castings were heavy, gray iron, designed to dampen the high-frequency vibrations caused by metal cutting.

Tooling & Turret Stations

The heart of the machine is the turret. Most Herbert models feature a 6-station hexagonal turret. The indexing mechanism relies on a Geneva drive or similar mechanical linkage, ensuring that the turret locks into the exact same position (repeatability within tenths of a thousandth of an inch) every time.

Additionally, the cross-slides often featured “square turrets” holding four more tools, allowing for parting off, grooving, and facing operations independent of the main turret.

Spindle & Drive Systems

Drive systems ranged from flat belts on very early antique models to V-belts and geared headstocks on the classic 2D and 4 series. Power ratings were generous; a No. 4 Senior might utilize a 5 to 7.5 HP motor, delivering immense torque at low RPMs for drilling large holes in steel.

Most models were designed for collet chucks (for bar work) or 3-jaw chucks (for individual billets). The bar-feed mechanism utilized gravity weights or pneumatic pushers to advance the stock through the hollow spindle.

Automation Enhancements

Even on manual machines, Herbert incorporated “power feeds.” A driveshaft running the length of the bed allowed the operator to engage a clutch, making the turret or cross slide move automatically at a set feed rate per revolution. This ensured a consistent surface finish that hand-feeding could never match.

Industrial Applications

Mass-Production Work

The primary application for Herbert lathes was the mass production of repetitive cylindrical parts. If a factory needed 5,000 identical specialized bolts for a tank engine, they used a Herbert. The setup time might take two hours, but once set, an operator could produce a part every 45 seconds. Common outputs included threaded studs, plumbing fittings, automotive bushings, and hydraulic valve stems.

Metal Spinning & Forming

While not their primary design, capstan lathes were occasionally used for metal spinning—flowing a disc of sheet metal over a mandrel to create shapes like bowls or light reflectors. The heavy-duty bearings of the Herbert spindle could withstand the lateral pressure, though specific tool rests were usually required to replace the standard cross slide for this work.

High Precision Threading

Herbert is inextricably linked to the Coventry Die Head. This specialized tooling attachment allowed for “self-opening” threading. Unlike a standard die that must be unscrewed from the thread (reversing the lathe), the Coventry head automatically popped open when the thread reached the correct length. This allowed the tool to be withdrawn instantly without stopping the spindle, revolutionizing the speed of threading operations.

Herbert Lathes in Today’s Workshops

Why Enthusiasts Restore Them

For the modern hobbyist or small job shop, a Herbert lathe offers capability far beyond a standard bench lathe. They are incredibly rigid, meaning they can take deep cuts in stainless steel without chattering. Restoration enthusiasts admire the mechanical logic; these are machines that can be fixed with wrenches and scrapers, not software patches.

Buying Considerations

When purchasing a vintage Herbert, distinct wear points must be checked:

- Bed Wear: Check the “Flamard” ways near the headstock where 90% of the work happens.

- Turret Indexing: Does the turret lock up tight, or is there “slop” when you wiggle it?

- Clutches: On Preoptive models, slipping clutches are a complex repair.

- Accessories: A Herbert without its specific tool holders (box tools, die heads, collets) is limited. Tooling can be harder to find than the machine itself.

Market Prices & Collectability

Prices vary wildly. Because they are heavy (often 1.5 to 3 tons), “scrap value” sets the floor. A working but worn No. 2D might sell for £300–£800 ($400–$1000), effectively the price of the iron. However, a fully restored, “plug-and-play” model with a cabinet full of tooling can command £2,500 to £4,000. The 2M/3M Auto Robots are less desirable to hobbyists due to their pneumatic complexity and lack of manual feel.

Restoration Guide

Disassembly & Cleaning

Restoration begins with disassembly. These machines were often flooded with cutting oil, which over decades turns into a sticky, varnish-like resin. Industrial degreasers and steam cleaning are usually required. Note that components are heavy; an engine hoist or gantry crane is essential for removing the turret saddle or headstock.

Overhauling Slides, Bearings & Mechanisms

The “gibs” (strips that adjust the tightness of the slides) often need replacement or re-scraping to restore precision. Spindle bearings in Herbert lathes are usually high-precision tapered rollers or plain bearings in older models. If the spindle has excessive runout, bearing replacement is a precision task requiring clean-room practices.

The turret indexing mechanism often accumulates metal chips. Cleaning this internal gearing usually restores the crisp “click-clack” action of the index.

Electrical System Renewal

The electrical cabinets of the 1950s and 60s often contain obsolete contactors and oil-filled capacitors. For safety, most restorers strip the electricals.

- Phase Conversion: Most Herbert lathes are 3-phase industrial voltage (415V in the UK). Home workshops often use a Rotary Phase Converter or a Variable Frequency Drive (VFD) to run them on single-phase power.

- Control Cards (2M/3M): For the Auto Robots, the vintage logic cards are often dead. Some ambitious restorers rip out the old logic and replace it with a modern PLC (Programmable Logic Controller) or Arduino-based system to run the pneumatics.

Spare Parts & Tooling Sources

Original spares from the factory are non-existent. However, the UK has a robust network of used machinery dealers (like G & M Tools or reliable eBay breakers) who strip old machines for parts.

Fortunately, the “Coventry” die head inserts (chasers) are still manufactured or available as New Old Stock (NOS) because they became an industry standard.

Comparing Herbert Lathes with Other Heritage Brands

Ward, CVA, Colchester, Hardinge

- Ward: The H.W. Ward company was Herbert’s fiercest British rival. Ward lathes are very similar in capability. Generally, Ward capstans are considered slightly more agricultural and robust, while Herberts were seen as slightly more refined in their controls.

- CVA: Producing under license from Kearney & Trecker, CVA machines were incredibly high quality, often featuring more modern styling and higher spindle speeds than pre-war Herberts.

- Colchester: Known for engine lathes (like the Student or Master). A Colchester is more versatile for one-off repair work, but a Herbert destroys a Colchester in speed when making 50 of the same item.

- Hardinge: The American benchmark for super-precision. Hardinge lathes (like the HLV-H) are far more precise than a standard Herbert but lack the raw material removal rate and grunt of a Herbert No. 4.

Strengths and Weaknesses

Herbert Strengths: unparalleled vibration damping, longevity, availability of parts in the UK, ingenious Preoptive speed changing.

Herbert Weaknesses: Extremely heavy, large footprint, not suited for single “one-off” repair jobs (due to setup time), low maximum RPM on older models limits use with modern carbide tooling.

FAQs

What is the main difference between a turret lathe and capstan lathe?

The main difference lies in how the tool-holding turret is mounted. On a capstan lathe, the turret is mounted on a secondary slide (ram) that moves within a saddle, allowing for fast, light operation. On a turret lathe, the turret is mounted directly to the saddle which slides on the bed, providing greater rigidity for heavy work but slower operation.

Can bolts be made on a Herbert lathe?

Yes, manufacturing bolts is one of the primary functions of these machines. Using a box tool to turn the diameter and a Coventry self-opening die head to cut the threads, a skilled operator on a Herbert lathe can produce high-quality bolts faster than almost any manual method.

Can you spin metal on a capstan lathe?

Technically, yes, but it is not the machine’s intended purpose. You would need to remove the cross-slide and install a specialized spinning rest. However, the Herbert’s heavy-duty spindle bearings are certainly capable of withstanding the pressures involved in metal spinning.

Are Herbert lathes good for beginners?

They can be challenging for absolute beginners compared to a standard engine lathe. The controls are designed for production cycles, not simple experimentation, and they lack a “compound slide” for cutting tapers easily. However, for a learner interested in production engineering or manufacturing history, they are an excellent education in mechanical logic.

Are spare parts still available?

New parts from the original manufacturer are no longer available, as Alfred Herbert Ltd closed in the 1980s. However, the second-hand market is active. Enthusiasts typically source parts from machine breakers, online marketplaces like eBay, or by purchasing “donor” machines to keep a primary lathe running.

Conclusion

The Herbert Capstan and Turret lathes are more than just obsolete cast iron; they are monuments to a time when Britain was the workshop of the world. They represent a specific philosophy of engineering—one where weight, rigidity, and mechanical ingenuity solved the problems of mass production.

For the modern restorer or machinist, preserving a Herbert lathe is an act of stewardship. These machines built the engines, the aircraft, and the infrastructure of the 20th century. With the rise of CNC, their role has shifted from frontline production to heritage craft, but their ability to turn metal with precision and authority remains undiminished. Whether sitting in a museum or making chips in a home workshop, the Herbert lathe endures as an icon of industrial heritage.