In an era dominated by automated manufacturing and AI-driven design, the manual engine lathe remains the undisputed king of the machine shop for one-off repairs, prototyping, and fundamental fabrication. While CNC (Computer Numerical Control) machining offers speed for mass production, it cannot replicate the tactile feedback, immediate adaptability, or the foundational understanding of metallurgy that a manual lathe provides.

In 2025, the relevance of the manual lathe hasn’t diminished; it has evolved. Modern manufacturing now demands a hybrid skillset—machinists who can program a robot but also possess the intuition to turn a custom bushing on a manual machine when the software fails. Whether you are a gunsmith, an automotive restorer, or a fabrication shop owner, the ability to manipulate metal manually is a critical asset.

What You Will Learn:

By the end of this guide, you will understand exactly how to select the right machine for your needs. We will cover the top picks for 2025, how to decode confusing specifications like “swing over cross slide,” realistic budget expectations, and a robust framework for deciding when to stick with manual operation versus investing in CNC.

2. What Is a Manual Engine Lathe?

A manual engine lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

The term “engine” dates back to the industrial revolution when these machines were driven by steam engines. Today, it differentiates the standard shop lathe from other variations.

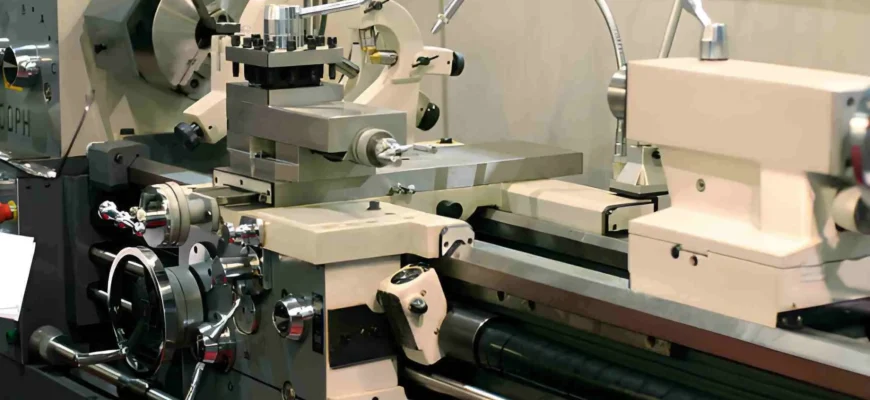

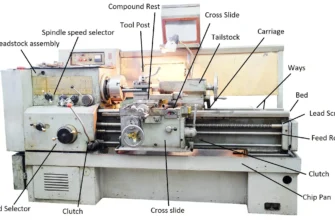

Core Components

To evaluate a lathe, you must understand its anatomy:

- The Bed: The heavy, rigid base (usually cast iron) that supports all other components. It features precision-ground “ways” (rails) on which the carriage rides.

- Headstock: Located on the left, it houses the main spindle, speed change gears (or pulleys), and the motor. This is the source of the machine’s power and precision.

- Tailstock: Located on the right, it can slide along the bed. It is used to support long workpieces with a “center” or to hold drill bits for axial hole creation.

- Carriage: The assembly that moves along the bed, carrying the cutting tool. It consists of the saddle, cross slide (moves perpendicular to the bed), and compound rest (swivels for angles).

- Lead Screw: A long, precision-threaded screw running the length of the bed, used to drive the carriage automatically for cutting threads.

Typical Uses

- Turning & Facing: Reducing diameter or creating a flat surface on the end of a part.

- Boring: Enlarging a drilled hole to a precise diameter.

- Threading: Cutting internal or external screw threads (UNF, UNC, Metric).

- Tapering: Creating conical shapes.

- Restoration: Repairing damaged shafts, resurfacing brake drums, or making obsolete parts.

Manual vs. Bench vs. Turret Lathes

- Engine Lathe: The standard, all-purpose floor-standing machine with automatic feeds.

- Bench Lathe: A smaller version of the engine lathe designed to be mounted on a workbench. often lacking the rigidity of a floor model but capable of high precision.

- Turret/Capstan Lathe: Designed for production. Instead of a simple tailstock, it has a rotating turret holding multiple tools for rapid sequential operations. These have largely been replaced by CNC turning centers.

3. Key Specs That Matter

When reading a spec sheet, it is easy to get lost in the numbers. Here is a breakdown of the specifications that actually impact your workflow.

Swing Over Bed vs. Swing Over Cross Slide

- Swing Over Bed: This is the absolute maximum diameter of a workpiece that can rotate over the main ways. A “14-inch lathe” has a swing of 14 inches.

- Swing Over Cross Slide: This is often the more critical number. Because the carriage sits on top of the bed, the saddle and cross slide reduce the available diameter. If you are turning a brake rotor or a large flywheel, the swing over cross slide determines if it fits.

Distance Between Centers (DBC)

This measures the maximum length of a workpiece the lathe can hold between the headstock and tailstock.

- Buyer Tip: You cannot use the full DBC for turning. You must account for the length of the chuck and the live center. A “40-inch DBC” might only give you 34 inches of usable turning length.

Spindle Bore and Speed Range

- Spindle Bore: The diameter of the hole passing through the headstock. If you are a gunsmith working on barrels, a 1.5-inch bore is often the minimum requirement. If the stock doesn’t fit through the bore, you are limited to the DBC length.

- Speed Range: Low speeds (40–100 RPM) are essential for threading and cutting hard steels or large diameters. High speeds (2000+ RPM) are necessary for small diameter work and polishing.

Bed Type & Material

- Cast Iron: The gold standard. Look for “hardened and ground” cast iron ways. Cast iron absorbs vibration (damping), which leads to a smoother surface finish.

- Welded Steel: Rarely used for engine lathe beds because it rings (vibrates) rather than absorbs energy.

- Rigidity: Mass is your friend. A heavier lathe resists deflection during heavy cuts.

Lead Screw, Feeds & Threading

Does the lathe have a separate feed rod and lead screw?

- Feed Rod: Saves wear on the precision lead screw during general turning.

- Quick Change Gearbox (QCGB): Essential for 2025. Avoid lathes that require you to manually swap gears to change thread pitches. A gearbox allows you to switch from cutting to threading with levers.

Motor Power & Control

- Single Phase (110V/220V): ideal for home shops.

- Three Phase (220V/440V): Common in industrial machines. Smoother power delivery but requires a converter for residential use.

- VFD (Variable Frequency Drive): The modern standard. It converts single-phase to three-phase and allows for infinite speed control via a dial, rather than shifting belts.

Precision & Tolerances

Factory specs (e.g., spindle runout <0.0005″) are a baseline. However, achievable precision often depends on setup. A generic import lathe can hold tight tolerances if the operator levels the bed correctly and adjusts the gibs.

Critical Accessories

- Chucks: 3-Jaw (self-centering for speed) and 4-Jaw (independent for precision and odd shapes).

- Steady Rest / Follow Rest: Essential for supporting long, thin shafts to prevent bowing.

- Quick Change Tool Post (QCTP): The single best upgrade for efficiency.

4. Price Ranges & What to Expect

The market in 2025 divides sharply by build quality and intended use.

Budget / Hobby ($400 – $2,000)

- Typical Machines: Mini Lathes (7×10, 7×14), micro-bench lathes.

- Expectations: Low rigidity, plastic gears (often a failure point), and significant “out of the box” tuning required.

- Trade-offs: You can make small parts (bushings, pins), but removing material from steel will be slow. Accuracy requires patience.

Prosumer / Light Industrial ($2,000 – $8,000)

- Typical Machines: 10×22 to 14×40 belt-drive or gear-head lathes. Brands like Precision Matthews, Grizzly (G series), or high-end imports.

- Expectations: Hardened ways, metal gears, QCTP included, better bearings, and significantly more mass (500–1,500 lbs).

- Trade-offs: Capable of gunsmithing and decent production work.

Industrial / Heavy Duty ($8,000+)

- Typical Machines: 14×40 and up, heavy cast bases, 5HP+ motors. Brands like Jet Elite, Clausing, or rebuilt American iron (Monarch, Hardinge).

- Expectations: Extreme rigidity. You can take a 0.200″ depth of cut in steel without the machine groaning.

- Trade-offs: Requires 3-phase power, concrete reinforced floors, and professional rigging to move.

Price Band Summary

| Category | Price Range | Typical Swing | Typical Weight | Target Buyer |

|---|---|---|---|---|

| Hobby | $400 – $2k | 7″ – 9″ | 80 – 250 lbs | Model makers, Learners |

| Prosumer | $2k – $8k | 10″ – 14″ | 400 – 1,200 lbs | Gunsmiths, Restorers |

| Industrial | $8k – $50k+ | 14″ – 20″+ | 2,000+ lbs | Job Shops, Production |

5. Top Picks: Best Manual Lathes for 2025

Note: Prices and availability fluctuate. Always check current listings.

A. Best for Beginners / Small Shop: [Archetype: 7×14 Mini Lathe]

- Summary: The classic starting point for model engineering and learning the basics.

- Best For: Learning, making small bushings, plastic, aluminum, and brass work.

- Key Specs: 7″ Swing, 14″ DBC, ~500W Motor.

- Price Range: $700 – $1,100

- Pros: fits on any workbench, runs on standard household outlets, huge community support/mods.

- Cons: Low rigidity, plastic change gears, requires “tramming” and cleanup before serious use.

- Recommended Accessories: Metal gear upgrade kit, 4-inch 4-jaw chuck.

B. Best for Precision & Hobbyists: [Archetype: Precision Matthews PM-1030V]

- Summary: A massive step up in quality with Variable Frequency Drive (VFD) and high-precision bearings.

- Best For: Serious hobbyists, small engine repair, high-tolerance part making.

- Key Specs: 10″ Swing, 30″ DBC, 1HP Brushless Motor, Power Cross Feed.

- Price Range: $2,800 – $3,500

- Pros: Power cross feed (rare in this size), VFD for torque at low RPM, very smooth operation.

- Cons: Heavy for one person to move (requires shop crane), stand often sold separately.

- Recommended Accessories: AXA Quick Change Tool Post, Digital Readout (DRO).

C. Best Value / Prosumer: [Archetype: Grizzly G4003G Gunsmith Lathe]

- Summary: The “Goldilocks” lathe for many shops—large enough for automotive work, precise enough for barrels.

- Best For: Gunsmithing, automotive shafts, general fabrication shop use.

- Key Specs: 12″ Swing, 36″ DBC, Camlock Spindle, Gearhead.

- Price Range: $4,500 – $6,000

- Pros: “Gunsmith” features usually mean a spider on the outboard side of the spindle (for supporting barrels), heavy cast iron stand included, very rigid.

- Cons: Gear changes can be noisier than belt drives; oil changes required.

- Recommended Accessories: Taper attachment, high-quality live center set.

D. Best Heavy-Duty / Production: [Archetype: Jet 1440 or Summit]

- Summary: A true industrial workhorse designed to run 8 hours a day.

- Best For: Job shops, heavy material removal, maintenance departments.

- Key Specs: 14″ Swing, 40″ DBC, 3-Phase 5HP Motor, 2″+ Spindle Bore.

- Price Range: $12,000 – $20,000+

- Pros: Massive rigidity allows for heavy roughing cuts; rapid foot brake; induction hardened gears.

- Cons: Requires industrial power infrastructure; large footprint.

- Recommended Accessories: Newall DRO, coolant system, Aloris Tool Post.

E. Best Refurbished / Classic: [Archetype: South Bend Heavy 10 or Monarch 10EE]

- Summary: Vintage American iron that, when restored, offers precision modern imports struggle to match.

- Best For: Purists, tool & die makers, those who appreciate history and extreme smoothness.

- Key Specs: Varies, but typically 10-13″ swing.

- Price Range: $1,500 (project) – $15,000 (fully rebuilt)

- Pros: Unmatched vibration damping, “super precision” capabilities (especially the Monarch 10EE), holds value.

- Cons: Spare parts can be rare/expensive; requires mechanical knowledge to restore; wear on the “ways” is a major risk.

6. Manual vs. CNC: How to Decide

For the digital product builder or modern entrepreneur, the allure of CNC (Computer Numerical Control) is strong. However, the manual engine lathe holds a specific strategic advantage.

Decision Framework

| Factor | Manual Lathe Wins When… | CNC Lathe Wins When… |

|---|---|---|

| Quantity | You are making 1 to 5 parts. | You are making 50 to 5,000 parts. |

| Complexity | Geometry is simple (cylinders, tapers, standard threads). | Geometry involves complex arcs, spheres, or multi-axis contouring. |

| Workflow | “I need a spacer now.” | “I need 100 spacers by Friday.” |

| Skillset | You want to learn the feel of metal cutting. | You are proficient in CAD/CAM and G-Code. |

| Setup Time | 2 minutes (chuck part, touch off tool). | 30+ minutes (program, set work offsets, tool offsets). |

The “One-Off” Rule

If a shaft on a conveyor belt breaks, you can walk to a manual lathe, measure the broken part, and machine a replacement in 20 minutes. On a CNC, you would need to model the part in CAD, generate the CAM toolpath, post-process the code, set up the tools, and dry-run the program. For repair work and prototyping, manual is faster.

The Hybrid Approach

In 2025, the line is blurring.

- DRO (Digital Readout): adding glass scales to a manual lathe gives you digital precision (0.0001″) without the programming. This is highly recommended for all manual lathes.

- Teach Lathes: These are CNC lathes that have handwheels. You can use them manually or “record” your manual movements to repeat them automatically.

- Retrofit: Converting a manual lathe to CNC is a popular project, but often results in a machine that is “okay” at both but excellent at neither.

Total Cost of Ownership (TCO)

- Manual: Purchase price + Tooling + Power. Low maintenance.

- CNC: Purchase price (3x manual) + Software subscriptions (CAD/CAM) + Tooling + Air compressor + Higher power bills + Specialized repair technicians.

7. Setup, Safety & First-Time Tips

Your machine is only as good as its setup.

Workshop Layout

- Clearance: Ensure you have 2-3 feet of clearance behind the lathe for maintenance access and chip cleanup.

- Lighting: Avoid fluorescent lights that flicker at 60Hz; this can create a strobe effect where a spinning chuck looks stationary. Use high-quality LED task lighting.

- Anchoring: Industrial lathes must be leveled and bolted to the floor (or placed on leveling pads) to prevent the bed from twisting under its own weight.

Essential PPE & Safety

- No Gloves: NEVER wear gloves while operating a lathe. Rotating machinery catches fabric and pulls hands in.

- Eye Protection: Polycarbonate safety glasses with side shields are non-negotiable.

- Hair/Clothing: Tie back long hair; roll up sleeves past the elbow. Remove rings and watches.

- Chuck Key: Never take your hand off the chuck key until it is removed from the chuck.

First-Time Setup Checklist

- Cleaning: Remove the factory packing grease (cosmoline) using kerosene or WD-40.

- Leveling: Use a precision machinist’s level. A twisted bed turns tapers. Adjust the feet until the bed is perfectly flat.

- Tailstock Alignment: Turn a test bar between centers. If the diameter varies from end to end, adjust the tailstock offset.

- Break-in: Run the lathe at low speed for 30 minutes, checking for bearing heat or odd noises.

8. Upgrades, Accessories & Maintenance

To get the most out of your investment, prioritize these upgrades.

High-Impact Upgrades

- Quick Change Tool Post (QCTP): Replaces the standard “lantern” or “4-way” post. Wedge-type QCTPs (Aloris style) allow you to swap tools in seconds with repeatable height accuracy.

- Digital Readout (DRO): Eliminates backlash calculation and counting handwheel turns. Essential for holding tight tolerances.

- Quality Chuck: A high-precision Set-Tru style chuck allows you to dial out runout for perfect concentricity.

Maintenance Plan

- Daily: Wipe down ways; apply way oil. Clear chips from the lead screw.

- Monthly: Check belt tension. Check oil levels in the headstock/gearbox.

- Yearly: Drain and replace gearbox oil. Check motor brushes (if applicable). Check gibs for play and adjust.

9. Common Mistakes & How to Avoid Them

- Under-sizing the Lathe: Buying a 7×10 mini lathe hoping to turn automotive brake drums. Fix: Always buy slightly more capacity than you think you need.

- Ignoring Rigidity: Focusing on “Swing” but ignoring machine weight. A light machine will chatter (vibrate) on steel, leaving a poor finish. Fix: Check the machine’s weight relative to its size.

- Using Cheap Tooling: Putting $2 carbide inserts on a $5,000 lathe. Fix: Buy high-quality HSS (High-Speed Steel) tooling or branded carbide inserts.

- Crashing the Compound: Running the tool post into the spinning chuck. Fix: Always rotate the chuck by hand once before turning the power on to ensure clearance.

10. Buyer’s Checklist & Comparison Matrix

Print this section when evaluating a used or new lathe.

Buyer’s Inspection Checklist

- Ways Condition: Are there deep scores, rust, or a “ridge” near the headstock (indicating heavy wear)?

- Spindle Runout: Put a dial indicator on the spindle nose. Is it under 0.0005″?

- Backlash: How much can you turn the cross-slide handle before the slide actually moves? (Over 0.010″ is sloppy but manageable; over 0.050″ is bad).

- Gear Noise: Run it in all gears. Are there clicking or grinding sounds (broken teeth)?

- Tailstock: Does the quill extend smoothly? Does it lock firmly?

- Parts Availability: Can you buy a replacement motor or half-nuts today?

Comparison Matrix Template

| Model | Swing / DBC | Spindle Bore | Motor | Weight | Best For |

|---|---|---|---|---|---|

| Model A | 7″ / 14″ | 0.8″ | 0.5 HP | 90 lbs | Small Hobby Parts |

| Model B | 10″ / 22″ | 1.0″ | 1 HP | 400 lbs | Precision / Gunsmithing |

| Model C | 12″ / 36″ | 1.5″ | 2 HP | 1,100 lbs | Auto Repair / Fabrication |

| Model D | 14″ / 40″ | 2.125″ | 5 HP | 2,200 lbs | Heavy Industrial |

11. FAQs

Is a manual lathe harder to learn than a CNC?

Initially, yes. Manual machining requires developing a “feel” for feeds and speeds. However, the learning curve is linear. CNC requires learning CAD, CAM, and setup before you can make a single cut.

Can I retrofit a manual lathe to CNC later?

Yes, usually by replacing lead screws with ball screws and adding stepper motors. However, it is often more cost-effective and accurate to buy a machine designed for CNC from the start.

What size lathe do I need for automotive shaft work?

A lathe with at least 12″ to 13″ of swing and 36″ to 40″ between centers is standard for automotive driveshafts and axles. A spindle bore of 1.5″ or larger is highly recommended.

How accurate are manual lathes for threads?

Very accurate. With a tight lead screw and a skilled operator, a manual lathe can cut Class 3 threads (aerospace tolerance).

Is a DRO (Digital Readout) worth the investment?

Absolutely. It reduces operator error, speeds up workflow by 50%, and helps compensate for older machines that may have backlash in the handwheels.

12. Conclusion & Next Steps

The manual engine lathe remains a cornerstone of mechanical innovation in 2025. Whether you are looking to prototype products for your business, restore classic machinery, or simply learn the craft of metalworking, there is no substitute for the versatility of a good manual machine.

Recommendation:

If you want the best: Search for a refurbished Monarch 10EE or a heavy-duty Jet.

If you are tight on space: Look at the [Model B: Precision Matthews 1030V] class.

If you need to make money with it immediately: The [Model C: Grizzly G4003G] offers the best balance of power and precision.