Unleashing Precision in Your Home Woodworking Shop

The allure of transforming a raw block of wood into a perfectly formed, functional, or artistic piece is at the heart of woodworking. For the modern hobbyist, the home workshop is a sanctuary of creativity, but space is often the ultimate constraint. This is where the mini wood lathe emerges not as a compromise, but as a powerful tool for precision. The rise of the DIY movement has fueled demand for compact yet capable machinery—73% of Millennials identify as DIYers, driving growth in the home workshop equipment market. This comprehensive guide to selecting and utilizing the best mini and compact wood lathes brings uncompromising accuracy to your home woodworking shop, whether you’re focused on pen turning, spindle work, or small bowls.

The Allure of Mini & Compact Wood Lathes for the Home Workshop

Mini lathes offer a compelling proposition: full-scale woodturning capability in a benchtop footprint. Specifically engineered for enthusiasts who may not have a dedicated, expansive workshop but still demand high-quality results, a mini lathe provides accessibility, lower initial investment, and surprising versatility. From intricate pens and detailed spindles to small bowls and custom tool handles, a benchtop wood lathe empowers artisans to explore the full spectrum of woodturning without surrendering valuable floor space. The focus on smaller projects inherently encourages greater attention to detail, making these machines perfect for precision-oriented work and woodturning mastery.

Defining “Precision Home Workshops” and Why it Matters

A “precision home workshop” is not defined by its size, but by its philosophy. It’s a space where accuracy, tight tolerances, and a flawless finish are the primary goals. In this context, the tools must be more than just functional; they must be extensions of the craftsman’s intent. Choosing a lathe machine for this environment means looking beyond basic specifications and evaluating features that contribute directly to control and repeatability. This mindset matters because it elevates woodworking from a simple craft to an art form, where the quality of the final piece is a direct reflection of the care and precision invested in its creation.

What This Guide Offers: A Focused Approach to Precision Lathe Selection and Use

This guide moves beyond generic buyer’s lists. It dissects the anatomy of a precision mini lathe, highlighting the components that separate a capable machine from a basic one. We review top-rated models specifically through the lens of their ability to deliver accuracy. Furthermore, we explore the essential accessories, techniques, and workshop setups that transform a good mini lathe into an exceptional woodturning system. Our goal is to equip you with the knowledge to not only choose the right lathe machine but to master its potential for creating truly precise work.

Understanding the Anatomy of a Precision Mini Wood Lathe

To select a machine that delivers uncompromising accuracy, you must first understand the components that make it possible. A mini wood lathe is a system where each part plays a critical role in stability, control, and the final quality of your woodturning project.

What Qualifies as Mini or Compact for Home Use?

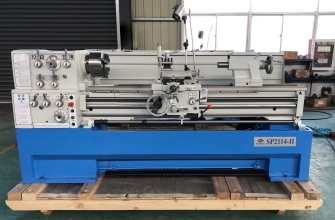

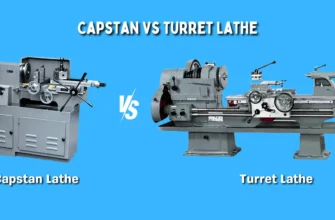

A mini or compact wood lathe machine is typically defined by its capacity. These machines usually feature a “swing over bed”—the maximum diameter of a workpiece—of 8 to 12 inches. The “distance between centers,” which dictates the maximum length of a workpiece, generally falls between 12 and 20 inches. Their benchtop lathe design is a key characteristic, allowing them to be placed on a sturdy workbench rather than requiring dedicated floor space. This smaller scale makes them ideal for home workshops where every square foot counts, without significantly limiting the scope of projects for hobbyists focused on smaller, detailed items such as turning kits and pen turning kits.

The Unique Precision Challenges and Advantages of Compact Models

The smaller size of mini lathes presents both challenges and advantages for precision work. A primary challenge is managing vibration. Lighter machines are inherently more susceptible to vibration, which can translate into tool chatter and a rough surface finish. However, their advantage lies in ergonomics and control. Working on a smaller scale allows for a more intimate connection with the workpiece. The shorter tool rest and bed allow for finer, more controlled tool movements, which is a significant benefit when turning intricate details on pens, finials, or other small-scale projects.

Key Components and Their Role in Achieving Uncompromising Accuracy

Every part of a lathe machine contributes to its overall precision. Understanding these components is crucial for making an informed choice.

Motor and Power: The heart of the lathe is its motor. For mini lathes, a variable speed DC motor is often preferred over an AC motor because it provides more consistent torque, especially at lower speeds. This consistent power is vital when making delicate cuts on hardwoods. Look for a motor with at least 1/2 HP, with 3/4 HP to 1 HP being ideal for more demanding work like turning small bowls.

Variable Speed Control: Perhaps the most critical feature for precision is electronic variable speed control. The ability to adjust the spindle speed on the fly without stopping to change a belt is a game-changer. A wide RPM range allows you to set the optimal speed for the task at hand—slower for large, unbalanced blanks and faster for sanding and finishing. This fine-tuned control minimizes tear-out and results in a smoother surface.

Headstock and Spindle: The headstock houses the drive mechanism and the spindle, which rotates the workpiece. A high-quality spindle with precision-ground bearings is essential to minimize “runout” or wobble. The spindle thread (e.g., 1″ x 8 TPI) must be standard to ensure compatibility with a wide range of accessories like chucks and faceplates.

Tailstock: The tailstock provides support for the opposite end of a workpiece. For precision, it must align perfectly with the headstock spindle. A robust locking mechanism and a smooth-operating quill (the part that extends) are non-negotiable features. This alignment ensures that long spindles are turned true and that drilling operations are perfectly centered.

Tool Rest and Banjo: The tool rest is your guide and pivot point for turning tools. It must be easily adjustable and lock down rigidly. A poorly secured tool rest will vibrate, leading to inaccurate cuts. The banjo is the assembly that holds the tool rest, and its ability to slide smoothly and lock firmly is equally important for positioning and stability.

Top-Rated Mini & Compact Wood Lathes for Specific Precision Needs

Selecting the right mini wood lathe depends on your specific goals. Here are our top picks, evaluated for their ability to deliver precision for different types of woodturning projects in a home shop environment.

Best Overall for Versatile Precision Woodturning in a Home Shop

For the woodturner who wants to tackle everything from pens to small bowls with exceptional accuracy, a lathe with a powerful motor, wide variable speed range, and solid cast-iron construction is essential. Models like the Jet JML-1221VS (also designated JWL-1221VS) and the Laguna Revo 12|16 stand out in this category.

The Jet JML-1221VS features a 1 HP DC motor, providing ample power and torque across a broad RPM range (60-3600 RPM across three speed ranges). Its heavy cast-iron bed dampens vibration effectively, and its precision-machined headstock and tailstock ensure excellent alignment, which is critical for turning true, concentric forms. The lathe includes 24 integrated indexing positions and electronic digital readout for easy speed selection.

The Laguna Revo 12|16 offers similar capabilities with a variable speed 1 HP PWM (Pulse Width Modulation) motor that maintains consistent torque at all speeds, particularly beneficial for low-speed, high-torque work. It features a 12.5″ swing over bed and can accommodate outboard turning for bowl blanks up to 16″. The digital display and smooth forward-reverse transition make it exceptional for detailed work.

Ideal for Micro-Detail & Pen Turning Enthusiasts

Pen turners and hobbyists focused on miniature, detailed work require a lathe that prioritizes smooth operation at high speeds and exceptional control. The RIKON 70-105 Mini Lathe is a popular choice specifically designed for this purpose.

While more modest in power (1/2 HP), its design is perfectly suited for small-diameter work such as pen turning. Key features include five discrete speed ranges (500, 1,175, 1,850, 2,225, 3,200 RPM), a well-aligned tailstock for drilling precise pen blanks, and a compact tool rest that allows for intricate tool manipulation. The lathe is constructed of cast iron, minimizing vibration issues common in lighter machines. The focus here is less on raw power and more on finesse and the ability to maintain stability at the higher RPMs needed for a glass-smooth finish on small items, making it ideal for those interested in turning supplies and pen turning kits.

High-Performance Options for Small Bowl & Hollow Form Turning

Turning small bowls and hollow forms places unique demands on a mini lathe, requiring significant low-end torque to handle unbalanced blanks and the rigidity to support outboard turning or heavier cuts. The NOVA Comet II DR Midi Lathe is a strong contender, offering robust construction and a powerful 3/4 HP motor with a versatile speed range (250-4000 RPM via three pulley positions).

Its ability to reverse direction is a significant advantage for sanding, ensuring a flawless finish inside and out. The solid construction and reliable power delivery make it a capable machine for artisans pushing the boundaries of what a compact lathe can do. The digital readout display allows precise speed adjustments without stopping the lathe.

Great Value for Money: Achieving Precision on a Budget

For those entering the world of precision woodturning without a large budget, several brands offer excellent value. Lathes from WEN or Grizzly often provide features like electronic variable speed and cast-iron beds at a very competitive price point. The WEN LA3421 features an 8″ swing and 13″ distance between centers, with variable speed from 750-3200 RPM, making it suitable for pen turning and small spindle work.

While they may not have the same level of fit and finish as premium models, they are more than capable of producing highly accurate work. The key is to carefully inspect the machine upon arrival, ensuring the headstock and tailstock align properly and that all locking mechanisms are secure. These lathes prove that precision is accessible without breaking the bank.

A Note on CNC Mini Lathes for Automated Precision

The integration of Computer Numerical Control (CNC) is a growing trend in woodworking. While more common in commercial settings, compact CNC mini lathe machines are becoming more accessible for home workshops. These machines offer unparalleled repeatability for producing identical parts, perfect for small production runs of items like chess pieces or custom knobs. While they replace some manual skill with programming, the precision they offer is undeniable. In 2024, over 135,000 CNC woodworking machines were sold globally, indicating a clear trend toward automated accuracy in both commercial and advanced hobbyist settings.

Essential Accessories and Upgrades for Enhanced Precision

A great mini lathe is just the starting point. The right accessories and upgrades are what truly unlock its potential for high-precision work, transforming it from a basic tool into a comprehensive woodturning system.

Premium Workholding: Upgrading Chucks and Faceplates

The standard drive center and faceplate that come with most mini lathes are functional, but upgrading your workholding is the single most impactful step you can take to improve precision.

Four-Jaw Scroll Chuck: A high-quality four-jaw chuck is a non-negotiable accessory. It allows for the secure gripping of a workpiece from either the inside (for hollowing bowls) or the outside (for turning tenons). A well-made chuck ensures the piece is perfectly centered on the spindle’s axis of rotation, which is fundamental for creating symmetrical, balanced forms. Options with dovetail jaws provide superior holding power compared to serrated alternatives.

Precision Faceplates: For larger, flatter pieces like shallow platters, a robust, machined faceplate provides superior support compared to screwing directly into the wood. A quality faceplate will be perfectly flat and balanced, preventing vibration and ensuring the workpiece runs true.

The Edge of Precision: Quality Turning Tools and Sharpening Systems

Your lathe can only be as accurate as the tools cutting the wood. A set of high-quality High-Speed Steel (HSS) or carbide turning tools is essential. HSS tools offer the ability to be sharpened to a razor’s edge for the finest cuts, while carbide tools provide durability and ease of use with replaceable cutters. High-speed steel excels at producing clean edges and is cost-effective for hobbyists, while carbide maintains sharpness longer but is more brittle and expensive.

Regardless of your choice, a reliable sharpening system, such as a slow-speed grinder with a jig, is critical. A sharp tool cuts wood fibers cleanly, requiring less tool pressure and resulting in a smoother surface with less tear-out.

Precision Measurement Tools: Calipers, Dial Indicators, and Gauges

Precision woodturning relies on accurate measurement.

Digital Calipers: Essential for measuring diameters, depths, and tenon sizes with an accuracy of a thousandth of an inch. They are indispensable for creating parts that need to fit together perfectly, particularly important in bowl turning and complex projects.

Dial Indicators: For the ultimate in precision setup, a dial indicator with a magnetic base can be used to check for spindle runout or to ensure a workpiece is perfectly centered in a chuck. This tool is invaluable for verifying machine accuracy before critical work.

Gauges: Thickness gauges for bowl turning and profile gauges for replicating shapes ensure consistency and accuracy across projects.

Maintaining a Pristine Environment: Effective Dust Collection

Precision work requires clear visibility. A robust dust collector is not just about safety and cleanliness; it’s about accuracy. Fine dust can obscure layout lines and make it difficult to see the tool’s cutting edge interacting with the wood. A dedicated dust port near the headstock connected to a shop vacuum keeps the work area clear, allowing you to focus on the fine details.

Specialized Accessories for Specific Projects

Beyond the basics, specialized accessories can dramatically improve precision for specific tasks. Pen mandrels ensure that pen blanks are turned perfectly concentric to the brass tubes inside. Bowl coring systems allow for efficient material use. Steady rests provide additional support for long, thin spindles, preventing flexing and vibration that would otherwise ruin a delicate piece. These accessories expand the capabilities of your mini lathe machine.

Mastering Precision Techniques on Your Mini Wood Lathe

Owning a precision-capable mini lathe is only half the battle. Mastering fundamental techniques is what translates machine accuracy into flawless finished work. This requires a focus on control, stability, and a deep understanding of how the tool interacts with the wood.

Optimal Spindle Speed Selection for Different Materials and Cuts

Using the correct spindle speed is paramount. A general rule is “slower for larger, faster for smaller.” A large, unbalanced bowl blank should be started at the lowest possible speed to allow it to be trued up safely. As it becomes round and balanced, the speed can be increased. For spindle turning, higher speeds are generally used. The variable speed control on your mini wood lathe is your most important tool here; adjust it constantly to match the diameter of the wood you are cutting and the type of cut you are making. Finer finishing cuts and sanding are best done at higher speeds to achieve a smooth surface.

Tool Presentation and Cutting Angles for Smooth, Accurate Surfaces

How you present the tool to the wood is the essence of woodturning. The tool should be held firmly on the tool rest, which should be positioned as close to the workpiece as possible to minimize leverage and vibration. For most cuts, the goal is to slice the wood fibers, not scrape them. This is achieved by presenting the tool with the bevel rubbing against the wood just behind the cutting edge. Experimenting with different angles for your bowl gouge or skew chisel will reveal how to get the cleanest, most efficient cut on different types of wood.

Strategies for Minimizing Vibration and Chatter

Vibration is the enemy of a fine finish. On a compact wood lathe, this is a constant battle. Ensure your lathe is on a heavy, stable bench. If possible, add weight to the bench or stand. Keep your turning tools sharp, as a dull tool requires more pressure, which induces vibration. Take lighter cuts rather than aggressive, heavy ones. For long, thin spindles, use the tailstock for support whenever possible, and consider using a steady rest for extremely delicate pieces.

Sequential Turning and Precise Measurement for Achieving Tight Tolerances

For projects requiring multiple identical parts or pieces that must fit together, a systematic approach is key. Use digital calipers to constantly check your diameters. When turning a tenon to fit into a mortise (like a box lid), aim for a snug, friction fit. Turn the tenon slightly oversized, then take whisper-thin cuts, checking the fit after each pass until it’s perfect. Using story sticks or templates can help replicate shapes and sizes accurately across multiple components.

Precision Sanding and Finishing Techniques for Flawless Results

The precision you achieve in turning can be lost with poor sanding. Sand with the lathe turning at a moderate to high speed, starting with a lower grit and working your way up. It’s crucial to stop the lathe frequently and sand with the grain to remove any cross-grain scratches left by power sanding. Applying finish on the lathe at a slow speed ensures an even, smooth coat. For a high-gloss finish, techniques like friction polishing can yield spectacular, glass-like results.

Setting Up Your Home Workshop for Optimal Precision

The environment in which you work has a direct impact on the quality of your results. A well-organized, stable, and well-lit workspace is not a luxury but a prerequisite for achieving precision in wood turning. This setup ensures you can focus entirely on the craft without fighting your surroundings.

Workspace Design: Lighting, Stability, and Ergonomics for Focused Work

Lighting: Excellent lighting is non-negotiable. Overhead ambient light should be supplemented with bright, adjustable task lighting aimed directly at the workpiece. This eliminates shadows and allows you to clearly see the tool’s cutting edge and the surface of the wood, which is critical for making fine, detailed cuts.

Stability: Your mini lathe must be mounted to a heavy, stable workbench that does not rock or vibrate. Any movement in the bench will be transferred to the lathe, compromising the finish of your work. Consider bolting the bench to the wall or floor and adding extra weight to its lower shelves to increase mass and dampening.

Ergonomics: Position your lathe so the spindle’s centerline is at or slightly below your elbow height. This allows you to control the tools with your body, not just your arms, reducing fatigue and increasing control. Keep your most-used tools, chucks, and measuring devices within easy reach to maintain a smooth workflow.

Power Requirements: Ensuring Consistent, Reliable Electricity for Your Lathe

A mini wood lathe’s motor, especially one with electronic variable speed control, performs best with a consistent supply of electricity. Plug the lathe into a dedicated circuit if possible to prevent power fluctuations that can occur when other large tools, like a dust collector or air compressor, cycle on. Using a heavy-gauge extension cord is essential to avoid voltage drop, which can strain the motor and affect its performance. A stable power supply ensures the motor delivers the consistent torque and speed needed for precision cuts, from roughing out a blank to applying a delicate finish.

Conclusion: Transforming Your Precision Woodturning Practice

The pursuit of precision is at the core of fine woodworking, and the mini wood lathe has proven itself to be an exceptionally capable tool for the modern home workshop. It is no longer a tool of compromise but a gateway to intricate detail and flawless execution in a compact footprint. As the woodworking market continues to expand—with projections showing it will grow from USD 5.23 billion in 2025 to USD 7.88 billion by 2032—the innovation and capability of these smaller machines will only increase.

By understanding the critical components—a powerful DC motor, responsive variable speed control, and a rigid, well-aligned structure—you can select a machine that serves as a solid foundation for accuracy. Elevating this foundation with essential accessories like a quality four-jaw chuck and sharp turning tools further enhances your capabilities. However, the ultimate precision comes from mastering the techniques of tool presentation, speed control, and vibration management, supported by a well-designed woodworking shop setup.

Your next step is to evaluate your own workshop space and project aspirations. Choose a mini wood lathe machine that not only fits your physical space but also aligns with your creative goals. Invest in the key accessories that will provide the greatest return in accuracy, and commit to practicing the fundamental techniques. By combining the right benchtop lathe with the right skills, you can transform your compact workshop into a hub of precision woodturning, creating pieces that reflect the highest standards of craftsmanship and attention to detail.

Whether your passion is pen turning, bowl turning, or exploring hollow forms, the path to precision starts with understanding your tool and the dedication to mastering your craft. The investment in a quality mini lathe and a commitment to precision technique will yield results that far exceed the modest footprint of your machine.