Key Highlights

- A lathe mill combo machine combines turning and milling functions, saving space and money in your machine shop.

- Choosing the right combination lathe involves assessing your specific project needs, from simple tasks to complex shapes.

- Key features to look for include a rigid build material like cast iron, variable spindle speed, and robust motor power.

- Benchtop and mini versions of the milling machine are perfect for small workshops, while heavy-duty models suit industrial use.

- The main advantage of a mill combo is workflow efficiency, as you don’t need to move workpieces between separate machines.

- Proper maintenance, including regular cleaning and lubrication, is essential for the longevity of your combo machine.

Introduction

Are you looking to expand your workshop’s capabilities without taking up too much space? A lathe and milling machine combo might be the perfect solution. These versatile tools merge the functions of two essential machines into a single, compact unit. Whether you’re a hobbyist just starting or a seasoned machinist, a combination machine can help you tackle a wide range of projects with precision and efficiency. This guide will walk you through everything you need to know to choose the right lathe mill for your needs.

Understanding Lathe and Milling Machine Combos

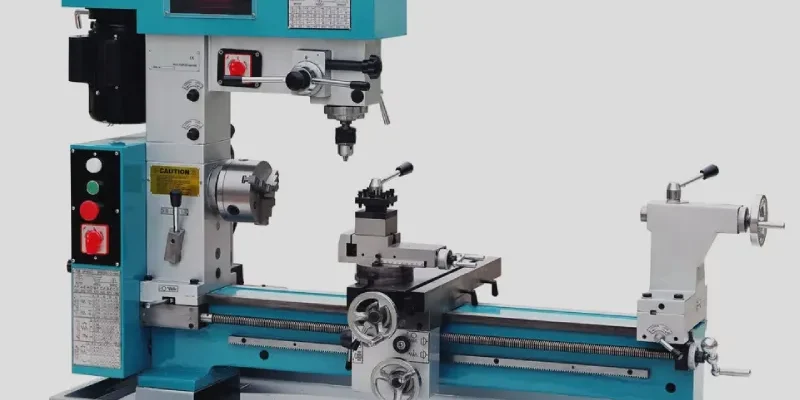

A combination lathe and milling machine, often called a mill combo, is a powerful tool that offers incredible versatility. By integrating two different machining processes into one frame, this combo machine becomes a go-to for workshops where space or budget is a concern. It allows you to perform both turning and milling operations without needing two separate, bulky pieces of equipment.

Understanding how these machine tools work and what makes them unique will help you decide if one is right for you. We will explore what a combination machine is, how it differs from standalone units, and the key advantages it offers.

What is a Lathe and Milling Machine Combo?

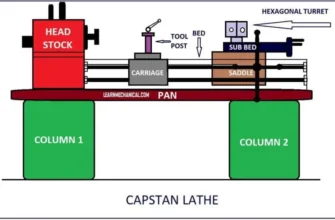

At its core, a lathe milling machine is a hybrid tool that brings together the capabilities of a lathe and a milling machine. A lathe spins a workpiece on an axis to perform operations like cutting, sanding, or turning. A milling machine, on the other hand, uses a rotating cutter to remove material from a stationary workpiece, allowing for more complex milling operations.

The combo machine integrates these functions, enabling you to switch between turning and milling on a single piece of equipment. This is a significant advantage for any machine shop, especially for those with limited floor space. You get the functionality of two essential machine tools without the footprint of both.

This consolidation streamlines the manufacturing process. Instead of setting up a project on a lathe and then moving it to a milling machine, you can often complete multiple steps on the same mill combo. This saves time and reduces the potential for errors, making your workflow much more efficient.

Key Differences Between Combo Machines and Standalone Machines

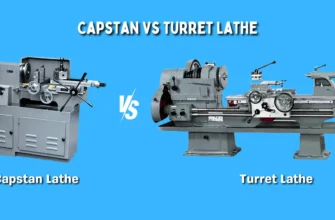

When you’re weighing your options, it’s important to understand the fundamental differences between a combination machine and separate, standalone machines. While a mill lathe offers great convenience, there are trade-offs to consider in terms of performance and functionality. The primary distinctions often come down to space, cost, and specialization.

Standalone machines are built for one purpose, which can sometimes mean they offer higher rigidity and power for very heavy-duty, industrial-scale tasks. A combination machine must balance two functions, which can impact its overall size and capacity. However, for most hobbyists and small shops, the performance of a combo is more than sufficient.

Here are some key differences:

- Space: A combination machine takes up significantly less floor space than two separate machine tools.

- Cost: Purchasing one combo machine is typically more budget-friendly than buying a separate lathe and mill.

- Workflow: You save time by not having to move a workpiece between machines, but you might need to change the setup between lathing and milling operations.

Main Advantages of Using a Combo Machine

Opting for a combo machine brings several compelling benefits to your machine shop, making it an attractive choice for many users. The most obvious advantage is the efficient use of space. For those working in a garage or a small commercial shop, a mill combo provides two-in-one functionality without demanding a large footprint.

Another major plus is cost savings. Investing in a single combination machine is almost always more economical than purchasing both a lathe and a milling machine separately. This allows you to allocate your budget to other essential tools or materials. The streamlined workflow is also a significant perk, as it reduces setup time and enhances productivity on projects that require both turning and milling.

Here’s a quick rundown of the main advantages:

- Space Efficiency: Combines two machines into one, ideal for smaller workshops.

- Cost-Effectiveness: Lower initial investment compared to buying two separate machines.

- Streamlined Workflow: Reduces the need to move workpieces, saving time and effort.

- Versatility: Capable of handling a wide array of tasks to meet your specific needs.

- Convenience: All your turning and milling tools are in one central location.

Core Features to Look for in a Quality Combo Lathe-Mill

When you’re ready to invest in a combination lathe, knowing which features to prioritize is key to making a smart purchase. A quality mill combo should deliver high precision, durability, and ease of use. Paying close attention to the machine’s specifications will ensure it can handle the projects you have in mind.

From the build material to the motor’s power, every component plays a role in the machine’s performance. You’ll want to examine the spindle speed, axis capabilities, and safety controls to find a combination machine that is both powerful and user-friendly.

Build Material and Rigidity

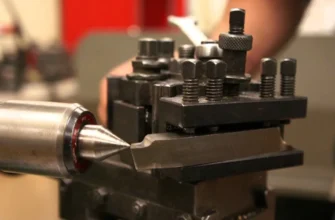

The build material of a lathe-mill combo is directly linked to its rigidity and, ultimately, its accuracy. An excellent machine is often constructed from cast iron. This heavy and dense material provides a stable foundation that absorbs vibrations during operation, which is crucial for achieving high precision. A machine that vibrates will produce sloppy cuts and poor surface finishes.

Look for features like hardened and ground bed ways. These surfaces allow the carriage and tailstock to slide smoothly and accurately, and their durability ensures the machine maintains its precision over years of use in your machine shop. The overall mill weight can also be an indicator of stability; a heavier machine is less likely to shift or flex under load.

A lack of rigidity is a common complaint with cheaper, lighter machines. Investing in a combo with a solid build ensures your cuts are true and your projects meet tight tolerances. Don’t underestimate the importance of a sturdy frame when searching for a reliable machine.

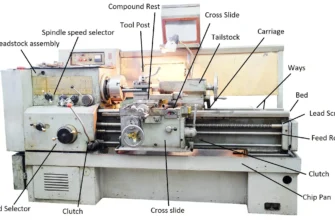

Spindle Speed, Motor Power, and Axis Capabilities

The heart of any lathe-mill combo is its motor and spindle system. Motor power determines the machine’s ability to cut through tough materials without bogging down. Some higher-end models feature independent motors for the lathe and mill functions, which can offer more consistent power and performance for both operations. A variable speed control is a must-have feature, as it allows you to adjust the spindle speed to suit the material and type of cut you’re making.

Axis capabilities refer to how the cutting tool can move. At a minimum, you’ll need a cross slide for moving the tool toward and away from the workpiece. More advanced machines might offer additional axes of movement, providing greater flexibility for complex jobs. Pay attention to the size of the spindle bore as well, as this determines the maximum diameter of the stock that can pass through the headstock.

Features like reverse switches can also be very useful, especially for tapping threads. When evaluating a machine, consider the range of its spindle speed and the robustness of its motor power to ensure it aligns with your intended projects.

Safety Features and User-Friendly Controls

Safety should always be a top priority in the workshop. A good combo machine will include several built-in safety features to protect you during operation. Look for things like a chuck guard, which prevents chips from flying toward you and keeps your hands away from the spinning lathe chuck. An emergency stop button that is easily accessible is another critical feature.

User-friendly controls make the machine easier and safer to operate, especially for beginners. Digital readouts (DROs) are a fantastic feature that provides precise measurements of the tool’s position, reducing guesswork and improving accuracy. Clearly labeled reverse switches and speed control knobs also contribute to a safer, more intuitive experience.

When purchasing, check for a manufacturer’s year warranty, as this can provide peace of mind and protection against defects. Ensuring the machine includes standard accessories like a drill chuck and proper guarding will help you get started safely and efficiently. Always read the manual thoroughly before your first use to understand all the controls and safety precautions.

Evaluating Your Workshop Needs

Before you buy a new machine, take a moment to evaluate your own workshop and project goals. The best lathe-mill combo for a large industrial machine shop is very different from the ideal choice for a hobbyist with limited shop space. Thinking about your specific needs will help you filter through the options and find the perfect fit.

Consider the size of your workspace, the types of projects you plan to tackle, and your own experience level. Answering these questions will guide you toward a machine with the right footprint, capabilities, and user-friendliness for your situation.

Size Considerations for Small Spaces

If your shop space is at a premium, a compact machine is the way to go. This is where benchtop combo machines and mini lathe combos truly shine. These models are designed to sit on a sturdy workbench, saving you valuable floor space that would otherwise be taken up by two separate machines.

When choosing a machine for a small workshop, look at its overall dimensions and mill weight. You’ll need to ensure your bench can safely support the machine’s weight. Beyond the physical footprint, consider the machine’s work envelope. This refers to the maximum size of a workpiece the machine can handle.

Make sure the work envelope is large enough for the projects you envision. While a mini lathe is great for small parts, it might be too restrictive if you plan to work on larger components. Balancing a compact size with adequate capacity is the key to finding the best combo for a small workshop.

Types of Projects Ideal for Combo Machines

A combination machine opens the door to an impressive variety of projects. Its dual functionality allows you to perform both turning and milling operations, making it an incredibly versatile tool for hobbyists and professionals alike. You can create parts with both cylindrical and flat surfaces without moving the workpiece to a different machine.

This makes them perfect for prototyping, repair work, and creating custom parts. Whether you’re making a custom bolt, shaping a metal bracket, or crafting intricate components for a model engine, a combo machine can handle a wide range of jobs. The ability to perform complex operations in a single setup is a major advantage.

Projects well-suited for a combination machine include:

- Turning custom shafts, pins, and bushings.

- Milling flat surfaces, slots, and keyways.

- Drilling precise holes and patterns.

- Cutting threads for screws and bolts.

- Creating parts with complex shapes that require both turning and milling.

- Prototyping and one-off custom parts.

Suitability for Beginners vs. Experienced Users

A combo machine can be an excellent choice for both beginners and experienced machinists, but the ideal model may differ based on skill level. For beginners, a simple, manual combo machine offers a great way to learn the fundamentals of both lathing and milling without the overwhelming cost and complexity of two separate machines.

Many entry-level models are designed with user-friendliness in mind, making them less intimidating for someone new to the machine shop. As a beginner, you can develop core skills in turning, facing, drilling, and milling on one versatile machine.

For a veteran machinist, a more advanced combo machine, such as a CNC lathe model, might be more appealing. These machines offer higher precision, automation, and the ability to execute complex programs.

- For Beginners: A manual combo machine is a great learning tool.

- For Experienced Users: A high-precision or CNC lathe combo offers advanced capabilities.

- Overall: They provide a cost-effective way for anyone to add both turning and milling to their workshop.

Popular Types and Models Available in the United States

The market offers a wide variety of lathe-mill combos, from compact units for hobbyists to large, industrial machines. In the United States, you can find everything from a mini lathe perfect for a small garage to a heavy-duty combination gunsmithing lathe designed for specialized, high-precision work.

Popular types include benchtop models, advanced CNC lathe options, and robust industrial machines like the Smithy Granite series. Understanding the different categories will help you narrow down your search and find a mill lathe that fits both your projects and your budget.

Multi-Purpose Mini and Benchtop Combos

For hobbyists, model makers, or anyone with limited shop space, a mini or benchtop combo is an ideal choice. These compact machines pack the essential functions of a lathe and milling machine into a single unit that can fit on a sturdy workbench. They are among the most budget-friendly options available, making metalworking more accessible.

A mini lathe combo is perfect for small-scale projects, such as making custom fittings, small engine parts, or jewelry. While they have smaller motors and a more limited work envelope than their larger counterparts, they are more than capable of handling common materials like aluminum, brass, and mild steel with precision.

The primary appeal of a benchtop mill combo is its ability to provide dual functionality without dominating your workshop. It’s a practical and economical starting point for anyone looking to get into machining or for professionals who need a small, secondary machine for quick jobs.

CNC Combo Machines for Precision Work

For those who require the utmost precision and repeatability, a CNC combo machine is the ultimate tool. CNC, which stands for Computer Numerical Control, uses a computer to automate the machine’s movements. You create a digital design, and the CNC lathe and milling machine executes the cuts with incredible accuracy.

These machines are ideal for producing complex parts with tight tolerances, making them popular in industries like aerospace, medical device manufacturing, and high-end prototyping. The performance of a CNC combination machine can rival that of standalone CNC machines for many applications, as they offer automated control over spindle speed, tool paths, and more.

While they represent a larger investment, a CNC milling machine combo boosts productivity significantly. The ability to run complex programs allows you to create identical parts repeatedly, reducing manual labor and the potential for human error. They are the top choice for any workshop focused on high-precision, automated production.

Heavy-Duty Industrial Lathe-Mill Options

When your projects demand more power and capacity, heavy-duty industrial lathe-mill combos are the answer. These machines are built for serious machining, featuring larger motors, greater mill weight for stability, and a much bigger work envelope. They can handle large, heavy workpieces and cut through tough materials with ease.

Brands like Smithy Granite are well-known in this category, offering robust machines that are popular in professional fabrication shops, repair facilities, and small manufacturing businesses. These heavy-duty models often come with more advanced features, such as power feeds on all axes and the option to add accessories like a rotary table for more complex milling.

If you’re working on large-scale projects like automotive parts, industrial components, or sizable custom fabrications, a heavy-duty machine is essential. They provide the rigidity, power, and capacity needed to tackle demanding jobs that smaller benchtop models simply cannot handle.

Performance Comparison: Combo vs. Separate Machines

One of the most common questions is how a combination machine stacks up against separate, standalone machines. A mill lathe offers undeniable convenience, but are there performance trade-offs? In general, for most hobbyist and light commercial work, a quality combo machine performs exceptionally well.

However, in a high-production, industrial environment, standalone machines might have an edge in power and rigidity. Let’s break down the comparison to help you understand the nuances in accuracy, workflow, and potential limitations.

Pros and Cons for Metalworking Accuracy

When it comes to accuracy, both combination and standalone machine tools can achieve high precision. The key factors are the machine’s rigidity, the quality of its components, and the operator’s skill. A well-built, heavy combo machine can be just as accurate as separate machines for most tasks.

The main difference emerges in extreme, heavy-duty applications. A dedicated industrial lathe or mill is designed for a single purpose, so its entire mass and structure are optimized for that task. This can give it a slight edge when taking very heavy cuts on tough materials. For a combination machine, the headstock that performs the metal lathe function may also double as part of the milling setup, which can introduce a small degree of compromise.

However, for the vast majority of users, this difference is negligible. A quality combo machine will deliver excellent precision for all but the most demanding industrial jobs.

| Feature | Combination Machine | Standalone Machines |

|---|---|---|

| Precision | Excellent for most tasks; may have slight compromises in extreme heavy-duty use. | Optimized for a single function, offering maximum rigidity and precision. |

| Setup | Single setup for multiple operations can improve overall project accuracy. | Requires moving the workpiece, which can introduce small alignment errors. |

| Rigidity | Generally good, but may be less than a dedicated industrial machine of the same size. | Typically higher, as the entire frame is dedicated to one type of force. |

Workflow Efficiency and Project Turnaround

This is where a combo machine truly excels. Workflow efficiency gets a massive boost because you don’t have to move your workpiece from one machine to another. Imagine you need to turn a shaft down to a specific diameter and then mill a keyway into it. On separate machines, you would have to unclamp the part from the lathe, carry it over to the mill, and set it up all over again.

With a combo machine, you can often perform both operations in a single clamping. You simply finish the turning, reconfigure the machine for milling, and cut the keyway. This drastically reduces setup time, which in turn speeds up your overall project turnaround.

For a busy machine shop or a hobbyist with limited time, this enhanced efficiency is a game-changer. It means less time spent on setup and more time spent making parts. While you may need to swap a tool or adjust the setup, it’s almost always faster than a complete machine changeover.

Common Limitations of Combo Machines

While combo machines are incredibly useful, it’s important to be aware of their common limitations before you buy. One of the most frequently cited drawbacks is the process of switching between lathe and mill functions. On some models, this can be a bit time-consuming, as you might need to move the milling head or other components.

Another limitation can be the work envelope. Because the machine has to accommodate both a lathe and a milling setup, the capacity for either function might be slightly smaller than what you’d find on a comparable standalone machine. For example, the swing over the bed or the size of the spindle bore might be more restrictive.

Here are a few common limitations to consider:

- Changeover Time: Switching between lathing and milling can require setup adjustments.

- Work Envelope: The size of workpieces may be more limited compared to dedicated machines.

- Simultaneous Use: You cannot use the lathe and mill functions at the same time.

- Power Compromises: Some entry-level models may have less power than standalone units.

- Accessory Use: Using accessories like a follow rest or steady rest might be more complex.

Price Range and Budget-Friendly Choices

The price of a combo machine can vary dramatically, from a few hundred dollars for entry-level models to tens of thousands for premium, industrial-grade CNC units. This wide range means there are budget options available for nearly everyone, whether you’re a hobbyist setting up a home workshop or a business investing in new machine tools.

Understanding the differences between entry-level and premium models will help you find a machine that offers the best value for your money. You should also factor in the additional costs of tooling and accessories to get a complete picture of your total investment.

Comparing Entry-Level and Premium Models

Entry-level models of a combination lathe are typically smaller, benchtop units designed for hobbyists and light-duty work. These machines are a fantastic, budget-friendly way to get into metalworking. They generally have smaller motors and simpler controls but are perfectly capable of handling softer metals and smaller projects.

Premium models, on the other hand, are built for more demanding applications. These can include larger, heavy-duty manual machines or sophisticated CNC mill combo units. They offer more power, higher precision, greater capacity, and advanced features like digital readouts, power feeds, and stronger motors. They are also built with higher-quality materials for better rigidity and longevity.

Here’s a quick comparison:

- Entry-Level Models: Best for hobbyists, small projects, and limited budgets.

- Premium Models: Ideal for professional shops, heavy-duty work, and high-precision requirements.

- Warranty: Premium models often come with a better year warranty and support.

- Features: Expect more advanced features like variable speed and DROs on premium machines.

Additional Costs: Tooling, Accessories, and Upgrades

When budgeting for your new machine, remember that the initial purchase price is just the beginning. To get the most out of your lathe-mill combo, you will need to invest in tooling and accessories. These items are rarely included with the base machine and are essential for performing various operations.

The list of potential tooling is long, but some basics include cutting tools for the lathe, end mills for the milling machine, a quality vise, and a set of calipers for measuring. Depending on your projects, you might also need a boring bar for creating precise internal diameters, a different lathe chuck, or a drill bit set.

As you gain experience, you may want to consider upgrades to enhance your machine’s capabilities.

- Essential Tooling: Lathe cutting bits, end mills, and a vise.

- Useful Accessories: A quick-change or turret tool post, a boring bar, and clamping kits.

- Potential Upgrades: Digital readout (DRO) kits, power feeds, or a new lathe chuck.

- Milling Specifics: Collets for holding end mills are a must.

Where to Buy Reliable Lathe-Milling Machine Combos Online

Once you’ve decided on the type of combo machine you need, the next step is finding a reputable place to buy it. Thanks to the internet, you have access to a global market of suppliers. You can find these machines through specialized equipment dealers, major tool retailers, and large online marketplaces.

Shopping online gives you the ability to compare prices and specifications from numerous sellers. However, it’s important to buy from trusted suppliers to ensure you receive a quality machine and good customer support for your machine shop.

Trusted U.S. Suppliers and Online Marketplaces

In the United States, there are several well-regarded suppliers of machine tools. Many machinists prefer to buy from established US suppliers known for their customer service and support. These companies often carry popular brands like Jet, Grizzly, and Smithy Granite, and can provide expert advice to help you choose the right combination mill lathe.

Large online marketplaces like Alibaba.com, Amazon, and eBay also offer a vast selection of machines from suppliers around the world. These platforms are great for comparing a wide range of models and prices, from mini-lathes to heavy-duty industrial units. When using these sites, pay close attention to seller ratings and reviews.

Here are some places to look:

- Specialty Tool Retailers: Companies that focus on machine shop equipment.

- Direct from Manufacturers: Brands like Smithy sell directly to consumers.

- Large Online Marketplaces: Offer a huge selection from global suppliers.

- Industrial Supply Companies: Businesses like Grainger or MSC Industrial Supply.

Factors to Consider Before Purchasing Online

Buying heavy machinery online requires careful consideration. Before you click “purchase,” make sure you’ve done your homework to avoid any surprises. Shipping is a major factor; these machine tools are heavy, and freight costs can be significant. Look for suppliers who offer transparent shipping policies or promotions.

Customer support is another critical element. What happens if your machine arrives damaged or you need help with setup? Choose a seller with a good reputation for post-sale support. Check the details of the year warranty, including what it covers and how to make a claim.

Finally, double-check that the combo machine meets your specific needs.

- Shipping Costs: Confirm the total price including freight delivery.

- Warranty and Returns: Understand the policies before you buy.

- Customer Support: Look for sellers with positive reviews regarding service.

- Seller Ratings: Check feedback from other buyers on marketplaces.

- Voltage Requirements: Ensure the machine is compatible with your workshop’s electrical system (e.g., 110V or 220V).

- Included Accessories: See what comes with the machine to avoid buying duplicates.

Maintenance and Care Tips to Increase Longevity

Your combo machine is a significant investment, and proper maintenance is the best way to protect it. Regular care will not only extend the life of your machine tools but also ensure they continue to operate accurately and safely. A little bit of routine cleaning and lubrication goes a long way.

Ignoring maintenance can lead to premature wear, loss of precision, and costly repairs. By following a simple care regimen, you can keep your machine running smoothly for years to come. Let’s cover the essential steps for cleaning, lubrication, and troubleshooting.

Routine Cleaning and Lubrication

Routine cleaning is the most important maintenance task for any machine tool. After every use, take the time to brush away metal chips and wipe down all surfaces. Chips left on the ground bed ways can score the precision surfaces and cause premature wear, leading to inaccuracy. A clean machine is a happy and accurate machine.

Lubrication is equally critical. All moving parts, including the gears, bearings, and lead screws, need regular oiling to reduce friction and prevent wear. Your machine’s manual will specify the correct type of lubricant and the recommended oiling points and schedule. Using the wrong type of oil can do more harm than good.

Follow these simple steps for routine care:

- Clean After Use: Brush away all chips and filings from the bed, carriage, and slides.

- Lubricate Regularly: Follow the manufacturer’s guide for oiling all moving parts.

- Protect Surfaces: Apply a light coat of oil to unpainted surfaces like the bed ways to prevent rust.

- Inspect Often: Regularly check for any loose bolts or signs of wear.

Troubleshooting Common Issues

Even with proper care, you may occasionally run into issues with your machine tools. Knowing how to troubleshoot common problems can save you time and frustration. For example, if you notice a poor surface finish on your workpiece, the cause could be a dull cutting tool, an incorrect spindle speed, or vibrations from a loose part.

Inconsistent performance, such as a fluctuating spindle speed, might point to a loose drive belt or an issue with the motor. If you’re having trouble with threading operations, double-check that your change gears are installed correctly according to the chart on your combo machine.

Here are a few common problems and potential solutions:

- Vibrations or Chatter: Check for loose components, a dull tool, or an unbalanced workpiece.

- Inaccurate Cuts: Verify the alignment of the headstock and tailstock, and check for play in the slides.

- Motor Stalling: You may be taking too deep of a cut, or the drive belt could be slipping.

- Stripped Threads: Ensure your change gears setup is correct for the desired thread pitch.

- Poor Surface Finish: Try adjusting your spindle speed, feed rate, or sharpening your cutting tool.

Conclusion

Choosing the right lathe and milling machine combo can significantly enhance your metalworking experience, whether you are a beginner or an experienced machinist. By understanding the unique features, advantages, and limitations of these machines, you can make an informed decision that aligns with your workshop needs. From evaluating various models to considering your budget and maintenance requirements, each factor plays a crucial role in ensuring you select the best option for your projects. Remember, the goal is to find a reliable, versatile machine that not only boosts your productivity but also inspires creativity in your work. Explore your options today and elevate your metalworking skills!

Frequently Asked Questions

Is a lathe and milling machine combo good for first-time metalworkers?

Yes, a lathe mill combo is an excellent choice for beginners. It provides an affordable and space-saving way to learn the fundamentals of both turning and milling on a single combination machine. Entry-level models are often user-friendly, making them less intimidating than purchasing two separate, complex pieces of equipment.

What are the most common uses for a combo machine?

A combo machine is used for a wide range of jobs that require both lathing and milling. Common tasks include turning shafts, drilling holes, milling flat surfaces and slots, and cutting threads. With accessories like a boring bar, you can also create precise internal diameters, making it versatile for prototyping and repairs.

How do I ensure safe operation and proper setup for a combo lathe-mill?

To ensure safe operation, always read the manufacturer’s manual thoroughly before use. Familiarize yourself with all safety features, such as chuck guards and emergency stops. Ensure your combination machine is set up on a stable, level surface in your machine shop and always wear appropriate personal protective equipment, including safety glasses.